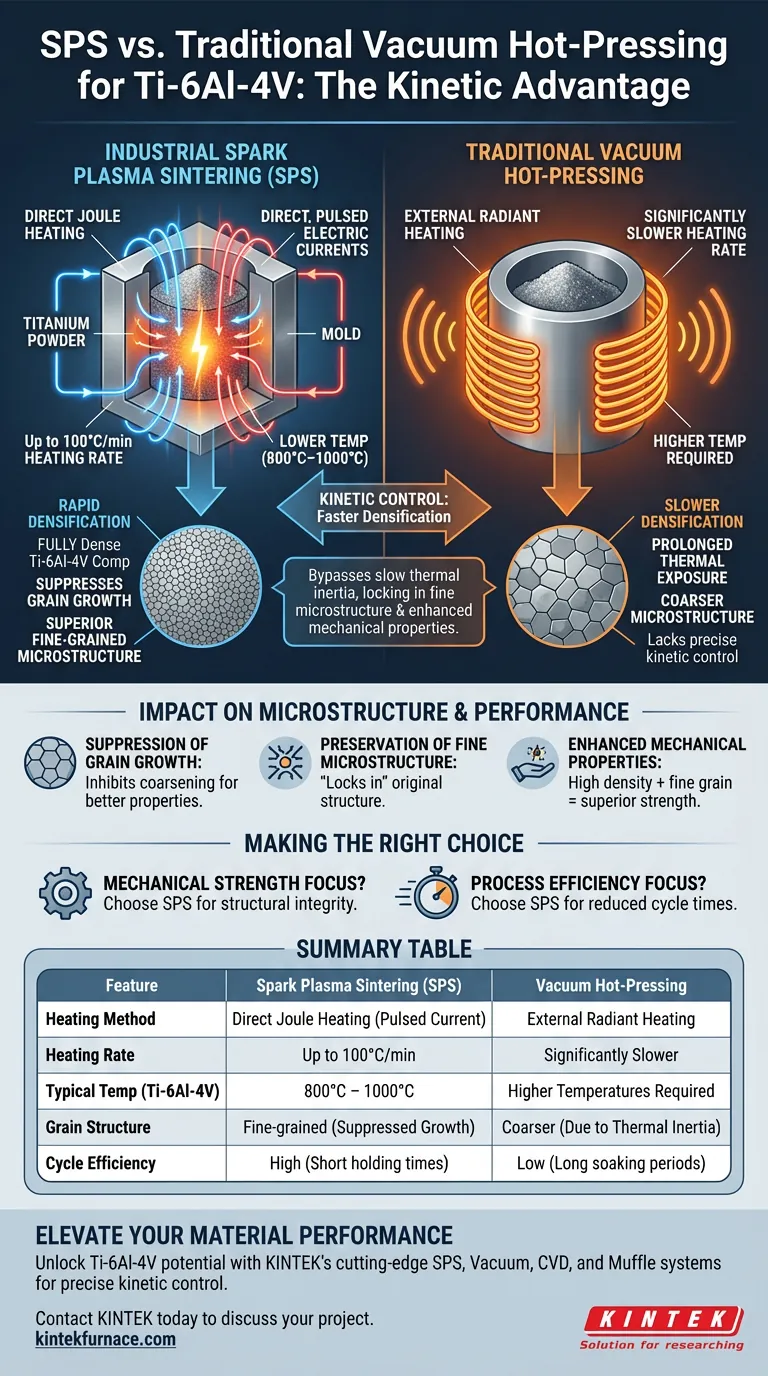

The primary advantage of Industrial Spark Plasma Sintering (SPS) systems over traditional vacuum hot-pressing lies in their ability to apply pulsed electric current directly to the titanium powder and mold. This "direct" heating method enables rapid heating rates of up to 100°C/min, allowing the Ti-6Al-4V alloy to reach near-full density at significantly lower temperatures (800°C–1000°C) while effectively suppressing grain growth.

The core difference is kinetic: SPS densifies the material faster than the grains can grow. By bypassing the slow thermal inertia of traditional furnaces, you achieve a fully dense Ti-6Al-4V component that retains a superior, fine-grained microstructure.

The Mechanism of Rapid Densification

Direct Joule Heating

Unlike traditional hot-pressing, which relies on external heating elements to radiate heat inward, SPS utilizes pulsed current. This generates Joule heating directly within the mold and the powder compact itself.

Superior Heating Rates

This internal heat generation allows for temperature increases as fast as 100°C/min. This is a drastic improvement over the slower ramp-up times required by conventional vacuum furnaces to ensure thermal equilibrium.

Lower Sintering Temperatures

Because the energy is applied so efficiently, Ti-6Al-4V can be sintered to high density at lower temperatures, specifically between 800°C and 1000°C.

Impact on Microstructure and Performance

Suppression of Grain Growth

The most critical metallurgical advantage of SPS is the inhibition of grain coarsening. In traditional processes, long exposure to high heat causes grains to enlarge, which can degrade mechanical properties.

Preservation of Fine Microstructure

By combining rapid heating with short holding times, SPS "locks in" the original microstructure of the powder. This results in a finished product with a finer grain structure compared to the coarser textures often found in hot-pressed materials.

Enhanced Mechanical Properties

The combination of high density and fine grain size directly translates to superior mechanical performance. The alloy maintains the strength benefits of the original powder feedstock without the embrittlement or coarsening associated with prolonged thermal exposure.

Understanding the Trade-offs

The Vacuum Hot-Pressing Benchmark

It is important to acknowledge that traditional vacuum hot-pressing is still a capable technology. It can achieve high relative densities (approx. 98%) and is effective for reducing residual porosity.

The Efficiency Gap

However, traditional hot-pressing achieves these results through extended cycle times and higher thermal loads. While it densifies the material, it lacks the precise kinetic control of SPS, making it more susceptible to altering the material's phase composition and grain size unfavorably.

Making the Right Choice for Your Goal

When selecting between SPS and traditional hot-pressing for Ti-6Al-4V, consider your specific engineering targets:

- If your primary focus is Mechanical Strength: Choose SPS to minimize grain growth and maximize the structural integrity of the alloy.

- If your primary focus is Process Efficiency: Choose SPS to significantly reduce cycle times via rapid heating rates and shorter holding periods.

By leveraging the direct energy delivery of SPS, you transform sintering from a passive thermal soak into an active, precision-controlled manufacturing step.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Vacuum Hot-Pressing |

|---|---|---|

| Heating Method | Direct Joule Heating (Pulsed Current) | External Radiant Heating |

| Heating Rate | Up to 100°C/min | Significantly Slower |

| Typical Temp (Ti-6Al-4V) | 800°C – 1000°C | Higher Temperatures Required |

| Grain Structure | Fine-grained (Suppressed Growth) | Coarser (Due to Thermal Inertia) |

| Cycle Efficiency | High (Short holding times) | Low (Long soaking periods) |

Elevate Your Material Performance with KINTEK

Unlock the full potential of Ti-6Al-4V and other advanced alloys with KINTEK’s cutting-edge thermal processing solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance SPS, Vacuum, CVD, and Muffle systems designed to give you precise kinetic control over your microstructure.

Whether you need to suppress grain growth or maximize process efficiency, our customizable lab and industrial furnaces are built for your unique requirements. Contact KINTEK today to discuss your project and see how our expertise can transform your manufacturing outcomes.

Visual Guide

References

- Yujin Yang. Optimization of large cast Haynes 282 based on thermal induced cracks: formation and elimination. DOI: 10.1051/meca/2024008

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the impact of precise temperature control in a sintering furnace? Optimize Cu/Ti3SiC2/C/MWCNTs Composites

- What makes the sintering process during hot pressing unbalanced? Speed vs. Microstructural Equilibrium

- How are vacuum hot pressing sintering furnaces classified based on their operating temperature? A Guide to Low, Medium, and High-Temp Ranges

- What are the primary applications of vacuum press technology in metalworking? Achieve Precision in Aerospace, Automotive, and Electronics

- How does an industrial-grade hot press sintering system benefit Al2O3/TiC/SiC(w) ceramics? Enhanced Material Density

- What are the technical advantages of Vacuum SPS systems for large transparent ceramics? Achieve Peak Optical Clarity

- What are the key steps in vacuum hot pressing? Achieve High-Density Materials for Demanding Applications

- Why is an industrial hot press critical for lunar ceramic components? Achieve Maximum Density and Impact Resistance