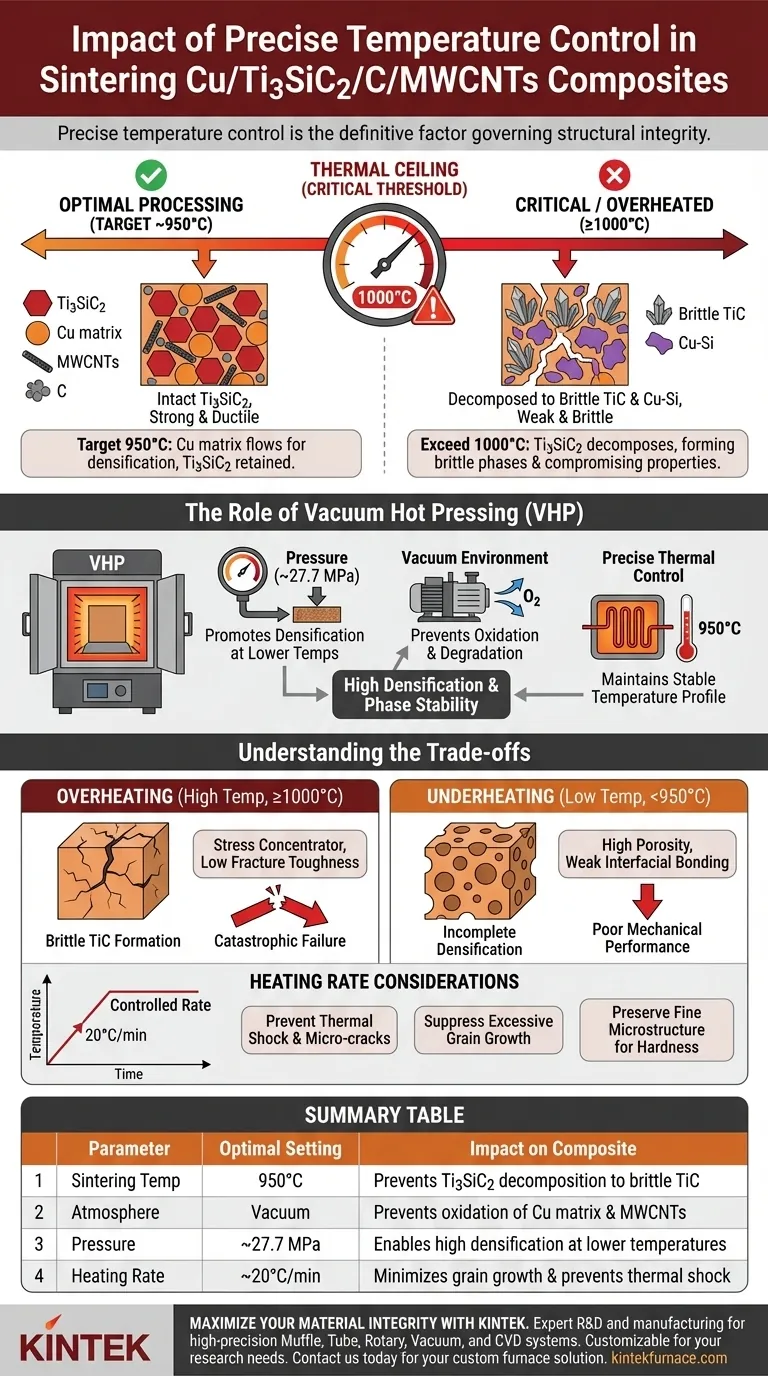

Precise temperature control is the definitive factor governing the structural integrity of Cu/Ti3SiC2/C/MWCNTs composites during fabrication.

If the sintering temperature exceeds the critical threshold (specifically reaching or exceeding 1000°C), the primary reinforcing phase, Ti3SiC2, undergoes thermal decomposition. This reaction transforms the desirable reinforcing phase into brittle Titanium Carbide (TiC) and Copper-Silicon (Cu-Si) compounds, severely compromising the material's mechanical properties.

Core Takeaway The fabrication of this composite requires a strict "thermal ceiling." You must maintain a stable sintering temperature (optimally around 950°C) to facilitate matrix flow and densification without triggering the chemical breakdown of the Ti3SiC2 reinforcement into brittle byproducts.

The Mechanism of Phase Stability

Avoiding Thermal Decomposition

The primary risk in sintering this composite is the instability of Ti3SiC2 at elevated temperatures.

While Ti3SiC2 provides excellent mechanical reinforcement, it is thermally sensitive in the presence of copper.

If the furnace temperature fluctuates upwards to 1000°C, the Ti3SiC2 phase decomposes. Instead of a reinforced composite, you are left with a matrix contaminated by brittle TiC phases and Cu-Si compounds.

The Optimal Processing Window

To prevent this degradation, the equipment must maintain a stable temperature profile, typically targeting 950°C.

At this temperature, the copper matrix softens sufficiently to flow and densify under pressure.

Crucially, this temperature is low enough to preserve the chemical structure of the Ti3SiC2, ensuring the composite retains its intended ductility and strength.

The Role of Vacuum Hot Pressing (VHP)

Integrating Pressure with Temperature

Precise thermal control does not work in isolation; it must be paired with mechanical pressure.

A Vacuum Hot Pressing (VHP) furnace applies significant pressure (e.g., 27.7 MPa) alongside the heat.

This pressure promotes the plastic deformation and flow of the copper particles into voids. This allows for high densification at 950°C, preventing the need to raise temperatures to the dangerous 1000°C level purely for density.

Preventing Oxidation via Vacuum

The vacuum environment is the third pillar of phase stability.

High temperatures usually accelerate oxidation. In a vacuum, atmospheric oxygen is eliminated.

This prevents the copper matrix from forming oxide inclusions and protects the Carbon Nanotubes (MWCNTs) and Ti3SiC2 from degrading or burning off before the composite is fully formed.

Understanding the Trade-offs

The Consequence of Overheating (High Temp)

As noted, exceeding the target temperature leads to phase transformation.

The formation of brittle TiC acts as a stress concentrator within the material. This significantly reduces fracture toughness, making the final component prone to catastrophic failure under load.

The Consequence of Underheating (Low Temp)

Conversely, failing to reach the optimal sintering temperature results in incomplete densification.

If the temperature is too low, the copper matrix viscosity remains too high to fill interstitial pores.

This results in a porous structure with weak interfacial bonding between the copper and the reinforcements, leading to poor mechanical performance.

Heating Rate Considerations

Precision also applies to how fast you reach the target temperature.

Programmable control (e.g., 20°C/min) helps balance the densification rate with grain growth.

Controlled heating prevents thermal shock, which can cause micro-cracks, and suppresses excessive grain growth, preserving the fine microstructure necessary for hardness.

Making the Right Choice for Your Goal

To optimize the sintering process for Cu/Ti3SiC2/C/MWCNTs composites, align your thermal strategy with your specific quality metrics:

- If your primary focus is Phase Purity: strictly cap your maximum temperature at 950°C to ensure zero decomposition of the Ti3SiC2 phase into brittle TiC.

- If your primary focus is Densification: maximize the mechanical pressure (e.g., ~27.7 MPa) within the vacuum environment to achieve full density without exceeding the thermal limit.

- If your primary focus is Microstructural Homogeneity: utilize programmable heating rates to prevent thermal shock and minimize grain growth during the ramp-up phase.

Success lies in navigating the narrow window where the copper flows freely, but the Ti3SiC2 remains chemically inert.

Summary Table:

| Parameter | Optimal Setting | Impact on Composite |

|---|---|---|

| Sintering Temp | 950°C | Prevents Ti3SiC2 decomposition into brittle TiC |

| Atmosphere | Vacuum | Prevents oxidation of Cu matrix and MWCNTs |

| Pressure | ~27.7 MPa | Enables high densification at lower temperatures |

| Heating Rate | ~20°C/min | Minimizes grain growth and prevents thermal shock |

Maximize Your Material Integrity with KINTEK

Precision is the difference between a high-performance composite and a brittle failure. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique research needs. Whether you are sintering advanced Cu/Ti3SiC2/C/MWCNTs composites or developing new alloys, our equipment ensures the stable thermal ceiling and vacuum environments required for phase purity.

Ready to elevate your lab's capabilities? Contact us today to find your custom furnace solution!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why does the reactive sintering process of RuTi alloys rely on the high vacuum environment provided by a vacuum hot press furnace? Essential for Purity and Density

- What are the advantages of using a Spark Plasma Sintering (SPS) system for UHTCs? Master Rapid Densification

- What types of shapes can be manufactured using vacuum hot pressing? From Simple Blocks to Complex Components

- Why is a high-vacuum environment required during SPS for transparent materials? Achieve Optical Purity

- How does a vacuum hot pressing furnace contribute to high-hardness composites? Achieve Near-Theoretical Density

- How do graphite molds function during the SPS of Ti-6Al-4Zr-4Nb alloys? Mastering Dual-Action Sintering

- How does hot-press sintering contribute to manufacturing high-density Ta-Al-C MAX phase ceramics? Optimize Consolidation

- How does the pressure-assisted mechanism in a Vacuum Hot Press Furnace improve YAG ceramics? Unlock Optical Clarity