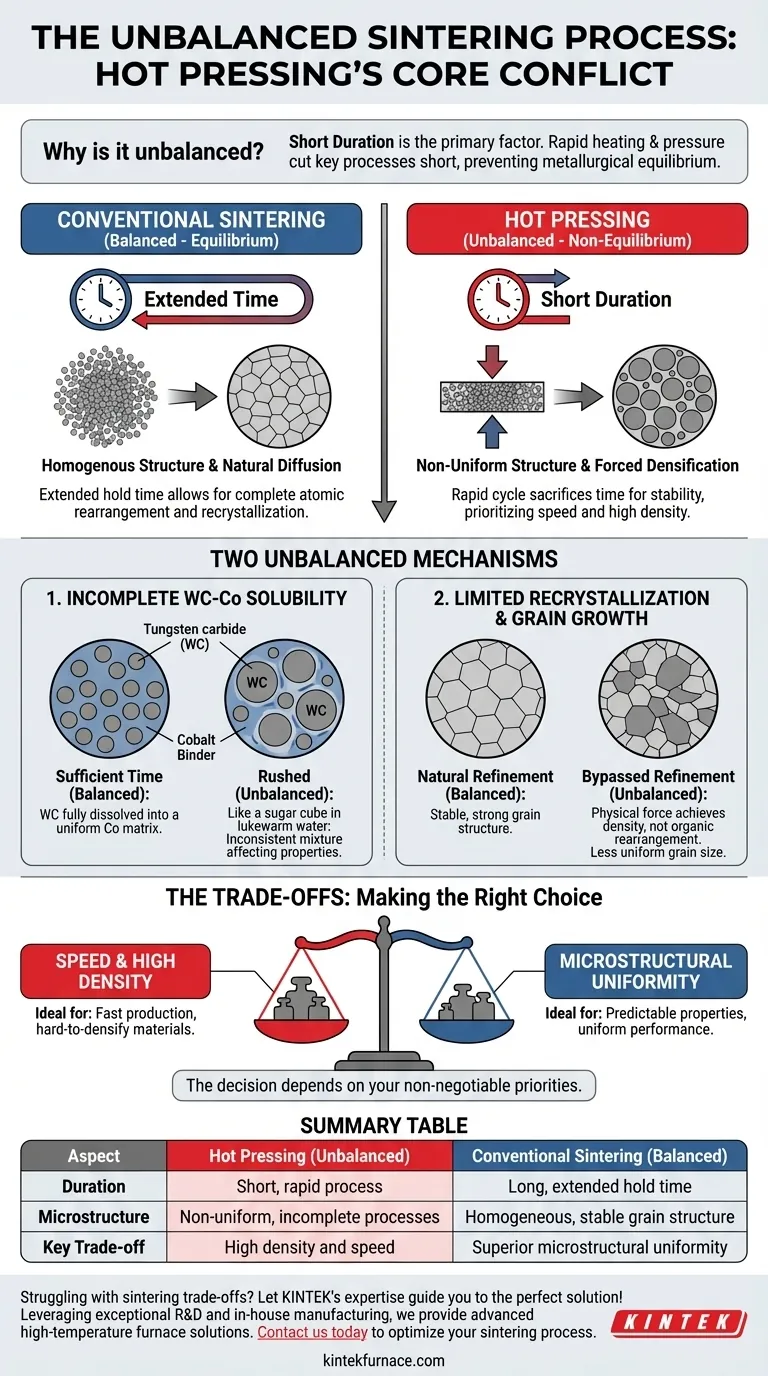

In essence, the primary factor that makes the hot pressing sintering process "unbalanced" is its short duration. The rapid heating and application of pressure do not allow sufficient time for the material to reach a state of metallurgical equilibrium. Key processes, such as the dissolution of tungsten carbide (WC) into cobalt (Co) and the recrystallization of grains, are cut short, leading to a non-uniform microstructure.

Hot pressing intentionally sacrifices the time needed for a material's internal structure to fully stabilize. This "unbalanced" state is a deliberate trade-off, prioritizing speed and high density over the microstructural perfection achieved in slower, equilibrium-based methods.

The Core Conflict: Time vs. Equilibrium

Hot pressing is fundamentally a non-equilibrium process. To understand why this matters, we must first define what a balanced, or equilibrium, state looks like in traditional sintering.

What "Equilibrium" Means in Sintering

In a conventional, longer sintering process, the material is heated and held at temperature for an extended period. This allows time for natural diffusion and rearrangement to occur.

Components like the hard WC phase slowly dissolve into the liquid cobalt binder, creating a homogenous solution. Simultaneously, smaller grains dissolve and re-precipitate onto larger ones, a process called recrystallization, which minimizes energy and creates a stable, strong grain structure.

The Role of Short Duration in Hot Pressing

Hot pressing accelerates densification by applying external pressure. The entire cycle—heating, pressing, and cooling—is much faster than conventional sintering.

This speed is the source of the imbalance. The process is completed before the material's atoms have enough time to naturally diffuse and settle into their most stable, low-energy positions.

Two Key Unbalanced Mechanisms

The "unbalanced" nature of hot pressing manifests in two critical microstructural processes that are left incomplete.

Incomplete WC-Co Solubility

For optimal properties in cemented carbides, the tungsten carbide (WC) must properly dissolve into the cobalt (Co) binder during the liquid phase of sintering. This requires time.

Hot pressing rushes this step. It's like trying to dissolve a sugar cube in lukewarm water by stirring it for only a few seconds. Some will dissolve, but you are left with an inconsistent mixture. This results in a non-uniform distribution of WC within the Co binder, affecting the final mechanical properties.

Limited Recrystallization and Grain Growth

Recrystallization is how the material refines its grain structure, leading to enhanced strength and toughness. This is a slow, methodical process of atomic rearrangement through the liquid phase.

Hot pressing largely bypasses this natural refinement. The external pressure physically forces the material particles together to achieve density, rather than allowing them to rearrange organically. This can result in a less uniform grain size and distribution compared to slower methods.

Understanding the Trade-offs: Speed vs. Homogeneity

Choosing hot pressing is a strategic decision that involves accepting a specific set of trade-offs. The unbalanced nature of the process is not necessarily a flaw, but a characteristic with distinct advantages and disadvantages.

The Advantage: Speed and Density

The primary benefit of hot pressing is its ability to achieve near-full density very quickly. This is especially valuable for materials that are difficult to densify using conventional, pressureless sintering. The result is a dense part produced in a fraction of the time.

The Consequence: A Non-Equilibrium Structure

The downside is the resulting microstructure. Because the process is unbalanced, it can lead to less predictable shrinkage, making it harder to control final part dimensions. Furthermore, the non-uniform microstructure may result in variations in properties like hardness and strength across the component.

Making the Right Choice for Your Goal

The decision to use hot pressing depends entirely on your project's non-negotiable priorities.

- If your primary focus is maximum density and production speed: Hot pressing is the superior choice, but you must implement tight process controls to manage the consequences of the non-equilibrium microstructure.

- If your primary focus is microstructural uniformity and predictable properties: A slower, conventional sintering process is often preferred, as it allows the material the time it needs to approach a stable equilibrium state.

Understanding this fundamental trade-off between processing speed and metallurgical equilibrium is the key to mastering your material's final performance.

Summary Table:

| Aspect | Hot Pressing (Unbalanced) | Conventional Sintering (Balanced) |

|---|---|---|

| Duration | Short, rapid process | Long, extended hold time |

| Microstructure | Non-uniform, incomplete processes | Homogeneous, stable grain structure |

| Key Trade-off | High density and speed | Superior microstructural uniformity |

| Ideal For | Fast production, hard-to-densify materials | Predictable properties, uniform performance |

Struggling with sintering trade-offs? Let KINTEK's expertise guide you to the perfect solution! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you prioritize speed, density, or microstructural control. Contact us today to optimize your sintering process and achieve superior results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength