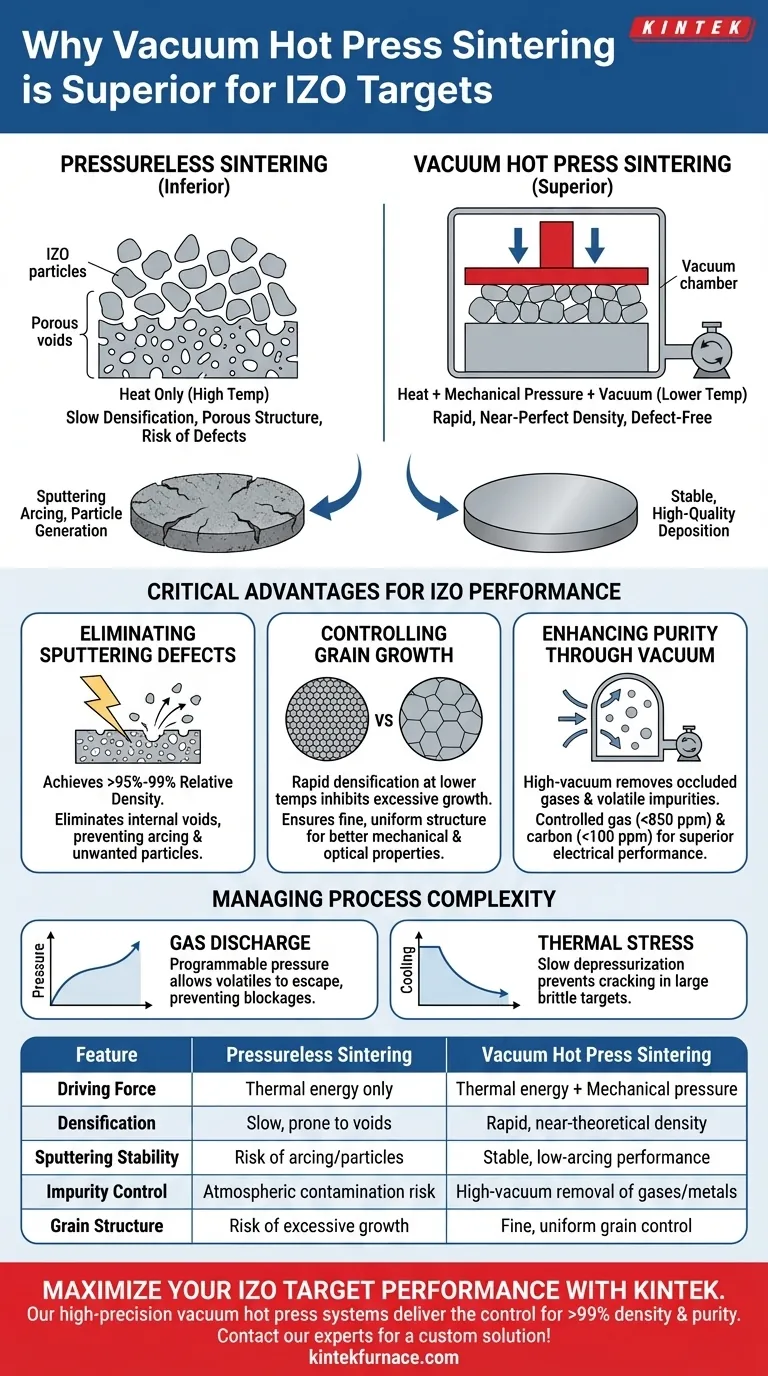

Vacuum hot press sintering is the superior manufacturing choice for high-performance IZO targets because it simultaneously applies mechanical pressure, high temperature, and a vacuum environment to the raw material. This combination forces particle rearrangement and plastic flow, accelerating densification to achieve near-perfect density at lower temperatures than pressureless methods, which is critical for preventing sputtering defects.

The Core Takeaway Pressureless sintering relies solely on heat, often leaving microscopic voids. Vacuum hot press sintering adds physical force to close these voids and a vacuum to extract impurities, resulting in a dense, defect-free target essential for stable, high-quality thin-film deposition.

The Mechanics of Superior Densification

Accelerating Particle Rearrangement

In pressureless sintering, particles bond slowly through thermal diffusion. Vacuum hot pressing introduces mechanical pressure (typically 5–30 MPa) as an additional driving force.

This external force promotes immediate contact and plastic flow among the powder particles. It physically forces grains together, significantly accelerating the elimination of pores that thermal energy alone might not close.

Achieving Density at Lower Temperatures

Because mechanical pressure aids the diffusion process, the material reaches full densification at significantly lower temperatures compared to pressureless methods.

This reduction in thermal load is crucial. It minimizes the risk of altering the chemical composition of the IZO material while ensuring the structural integrity of the final ceramic body.

Critical Advantages for IZO Performance

Eliminating Sputtering Defects

The primary enemy of a high-performance target is porosity. Internal pores in a target lead to sputtering arcing (electrical discharges) and the generation of unwanted particles during the coating process.

By achieving relative densities exceeding 95%–99%, vacuum hot pressing effectively removes these internal voids. This ensures a smooth, consistent deposition process essential for semiconductor and display applications.

Controlling Grain Growth

The rapid densification provided by hot pressing requires shorter holding times at peak temperatures. This effectively inhibits excessive grain growth.

Maintaining a fine, uniform grain structure significantly improves the mechanical properties of the target. For optical ceramics, this microstructure also enhances optical transmittance.

Enhancing Purity Through Vacuum

The process operates in a high-vacuum environment. This facilitates the removal of occluded gases and promotes the volatilization of low-melting-point metal impurities.

The result is a target with strictly controlled gas (<850 ppm) and carbon content (<100 ppm). High purity is non-negotiable for IZO targets, as impurities directly degrade the electrical performance of the sputtered film.

Managing Process Complexity and Risks

The Challenge of Gas Discharge

While pressure is beneficial, applying it too quickly can trap gases inside the powder compact.

To prevent blockages caused by poor gas discharge, programmable pressure functions are required. Pressure must be applied slowly during the heating phase to allow volatiles to escape before the outer shell seals completely.

Mitigating Thermal Stress

Large ceramic targets are brittle and prone to cracking under thermal stress.

Vacuum hot press furnaces mitigate this through precise depressurization. Slow depressurization during the cooling phase is essential to prevent the target from cracking due to rapid release of thermal and mechanical stress.

Making the Right Choice for Your Goal

When selecting a manufacturing method for IZO targets, prioritize vacuum hot pressing based on your specific performance requirements.

- If your primary focus is Sputtering Stability: Choose this method to maximize density and eliminate internal pores, which directly prevents arcing and particle contamination.

- If your primary focus is Film Purity: Rely on the vacuum environment to remove volatile impurities and occluded gases that would otherwise degrade electrical conductivity.

- If your primary focus is Structural Integrity: Utilize the programmable pressure capabilities to produce large-sized, crack-free targets with uniform grain structures.

Vacuum hot press sintering transforms the production of IZO targets from a simple heating process into a precision engineering operation, delivering the density and purity required for high-tech applications.

Summary Table:

| Feature | Pressureless Sintering | Vacuum Hot Press Sintering |

|---|---|---|

| Driving Force | Thermal energy only | Thermal energy + Mechanical pressure |

| Densification | Slow, prone to voids | Rapid, near-theoretical density |

| Sputtering Stability | Risk of arcing/particles | Stable, low-arcing performance |

| Impurity Control | Atmospheric contamination risk | High-vacuum removal of gases/metals |

| Grain Structure | Risk of excessive growth | Fine, uniform grain control |

Maximize Your IZO Target Performance with KINTEK

Don't settle for porous ceramic targets that lead to sputtering defects. KINTEK’s high-precision vacuum hot press systems deliver the mechanical pressure and thermal control necessary to achieve >99% relative density and superior chemical purity.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique lab and industrial needs. Whether you are producing advanced semiconductors or optical coatings, our technology ensures your materials meet the highest standards of structural integrity.

Ready to elevate your material science? Contact our technical experts today for a custom solution!

Visual Guide

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- What is the principle of hot pressing in manufacturing? Achieve High-Density Components with Precision

- Why is a vacuum hot press furnace required for sintering CNT-Al composites? Optimize Density and Interface Bonding

- What are the mechanical property advantages of AlxCoCrFeNi HEAs via VHPS vs Arc Melting? Unlock Superior Hardness

- Why is the synchronous axial pressure function of a Spark Plasma Sintering (SPS) furnace essential for MgTiO3-CaTiO3?

- What role does a vacuum hot press play in the consolidation of metallic glass powders? Expert Consolidation Insights

- How are vacuum hot pressing sintering furnaces classified based on their operating temperature? A Guide to Low, Medium, and High-Temp Ranges

- What role do hot press furnaces play in powder metallurgy? Achieve High-Density Components Efficiently