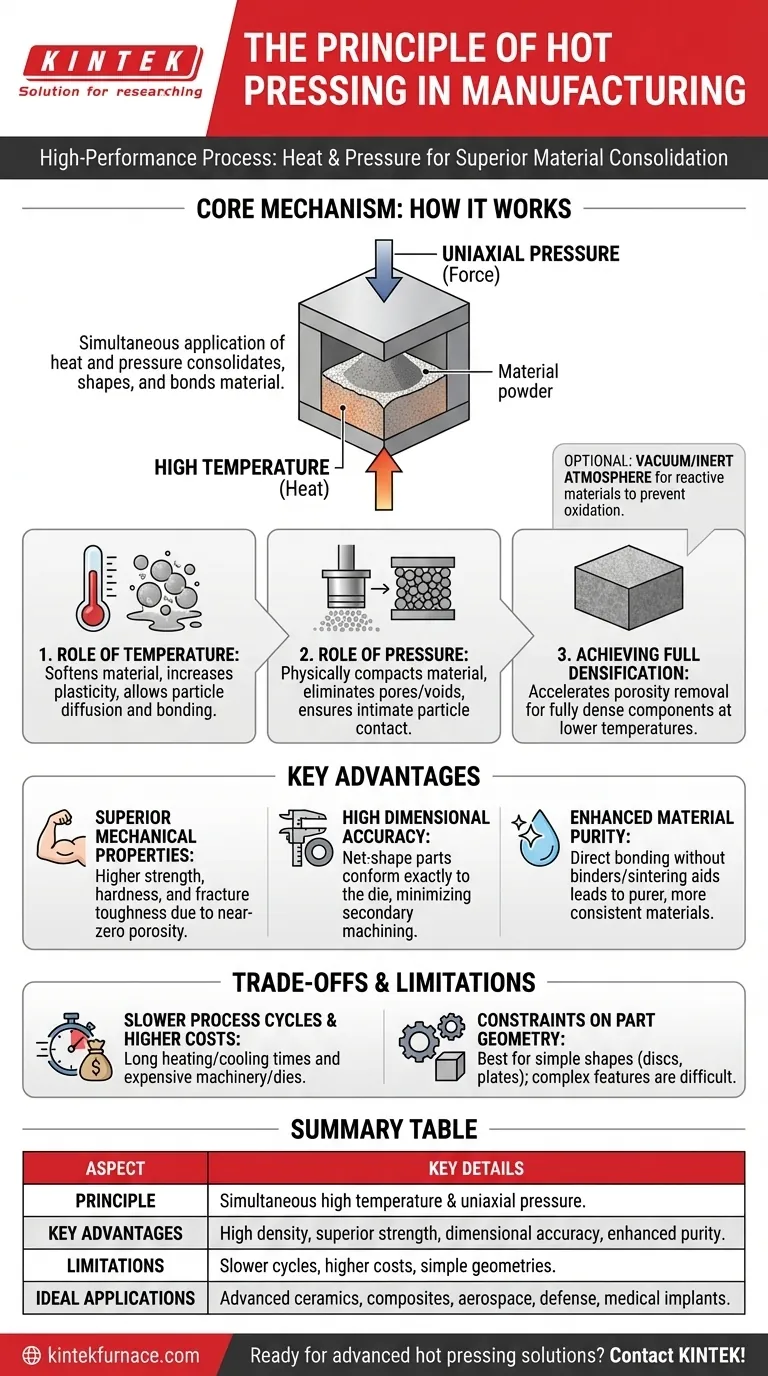

At its core, hot pressing is a high-performance manufacturing process that simultaneously applies high temperature and pressure to a material contained within a die. This dual action consolidates, shapes, and bonds the material, allowing for the creation of components with exceptionally high density and superior mechanical properties that are difficult to achieve through other methods.

The fundamental principle of hot pressing is not just about shaping a part, but about using thermal energy to make the material pliable enough for pressure to eliminate internal voids, forcing particles into intimate contact to create a dense, monolithic structure.

How Hot Pressing Works: The Core Mechanism

Hot pressing fundamentally changes a material's internal structure. It leverages the synergy between heat and force to overcome the limitations of using pressure or heat alone.

The Role of Temperature

The primary function of heat is to soften the material, increasing its plasticity. As the temperature rises below the material's melting point, its atoms can move more freely. This thermal energy makes the material significantly easier to deform and allows particles to diffuse and bond with each other.

The Role of Pressure

While heat makes the material pliable, uniaxial pressure provides the driving force for consolidation. This force physically compacts the material, collapsing internal pores and voids. The pressure ensures that the softened particles are pushed into intimate, uniform contact, which is the prerequisite for strong bonding.

Achieving Full Densification

The combination of heat and pressure accelerates densification—the process of removing porosity from a starting material. This synergy allows for the creation of a fully dense or near-fully dense component at lower temperatures and pressures than would be required by other processes, minimizing thermal stress and unwanted grain growth.

The Optional Vacuum Environment

For reactive materials like certain metals or advanced ceramics, hot pressing is often performed in a vacuum or inert gas atmosphere. This controlled environment prevents oxidation and contamination at high temperatures, preserving the material's chemical purity and structural integrity.

Key Advantages of the Hot Pressing Process

The precise control over temperature and pressure gives hot-pressed components a distinct set of advantages, making it the preferred method for demanding applications.

Superior Mechanical Properties

Because hot pressing virtually eliminates porosity, the resulting parts exhibit significantly higher strength, hardness, and fracture toughness. With fewer internal voids acting as potential failure points, the component is stronger and more reliable under stress.

High Dimensional Accuracy

The material is consolidated within a rigid, high-precision mold (die). This process results in net-shape or near-net-shape parts that conform exactly to the mold's dimensions. This minimizes or eliminates the need for costly and time-consuming secondary machining.

Enhanced Material Purity and Bonding

Hot pressing can create direct, solid-state diffusion bonds between material particles without the need for binders or sintering aids. These additives can often become weak points in the final component, so their elimination results in a purer material with more consistent properties throughout.

Understanding the Trade-offs and Limitations

Despite its benefits, hot pressing is not a universal solution. Its specialized nature comes with practical and economic trade-offs that are critical to understand.

Slower Process Cycles

Heating the tooling and material to the target temperature and then cooling it back down is an inherently slow process. These long cycle times make hot pressing less suitable for high-volume, rapid manufacturing when compared to processes like injection molding or stamping.

Higher Equipment and Tooling Costs

The machinery required to safely generate and contain extreme heat and pressure is expensive. Furthermore, the dies must be made from robust materials like graphite or ceramic composites that can withstand the harsh processing conditions, adding to the overall cost.

Constraints on Part Geometry

Hot pressing is typically best suited for producing parts with relatively simple geometries, such as discs, plates, or cylindrical shapes. Creating complex three-dimensional shapes with undercuts or intricate internal features is often difficult or impossible due to the nature of the uniaxial pressing.

Making the Right Choice for Your Application

Selecting a manufacturing process depends entirely on your project's primary objective. Hot pressing excels where performance and precision are non-negotiable.

- If your primary focus is maximum material performance: Hot pressing is the ideal choice for creating components with the highest possible density and strength, especially for advanced ceramics, metal matrix composites, and powder metallurgy parts.

- If your primary focus is precision with minimal finishing: This process is superior for manufacturing components to tight dimensional tolerances, making it a go-to for critical applications in aerospace, defense, and medical implants.

- If your primary focus is high-volume, low-cost production: For less demanding applications, alternative processes like conventional sintering, casting, or injection molding will almost always be more economical.

By mastering the interplay of heat and pressure, hot pressing transforms raw materials into components of exceptional quality and reliability.

Summary Table:

| Aspect | Key Details |

|---|---|

| Principle | Simultaneous application of high temperature and uniaxial pressure in a die to consolidate and shape materials. |

| Key Advantages | High density, superior strength, dimensional accuracy, and enhanced material purity without binders. |

| Limitations | Slower cycles, higher costs, and constraints on complex part geometries. |

| Ideal Applications | Advanced ceramics, metal matrix composites, aerospace, defense, and medical implants requiring precision and performance. |

Ready to enhance your manufacturing with advanced hot pressing solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact us today to discuss how our expertise can help you achieve superior material performance and efficiency in your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density