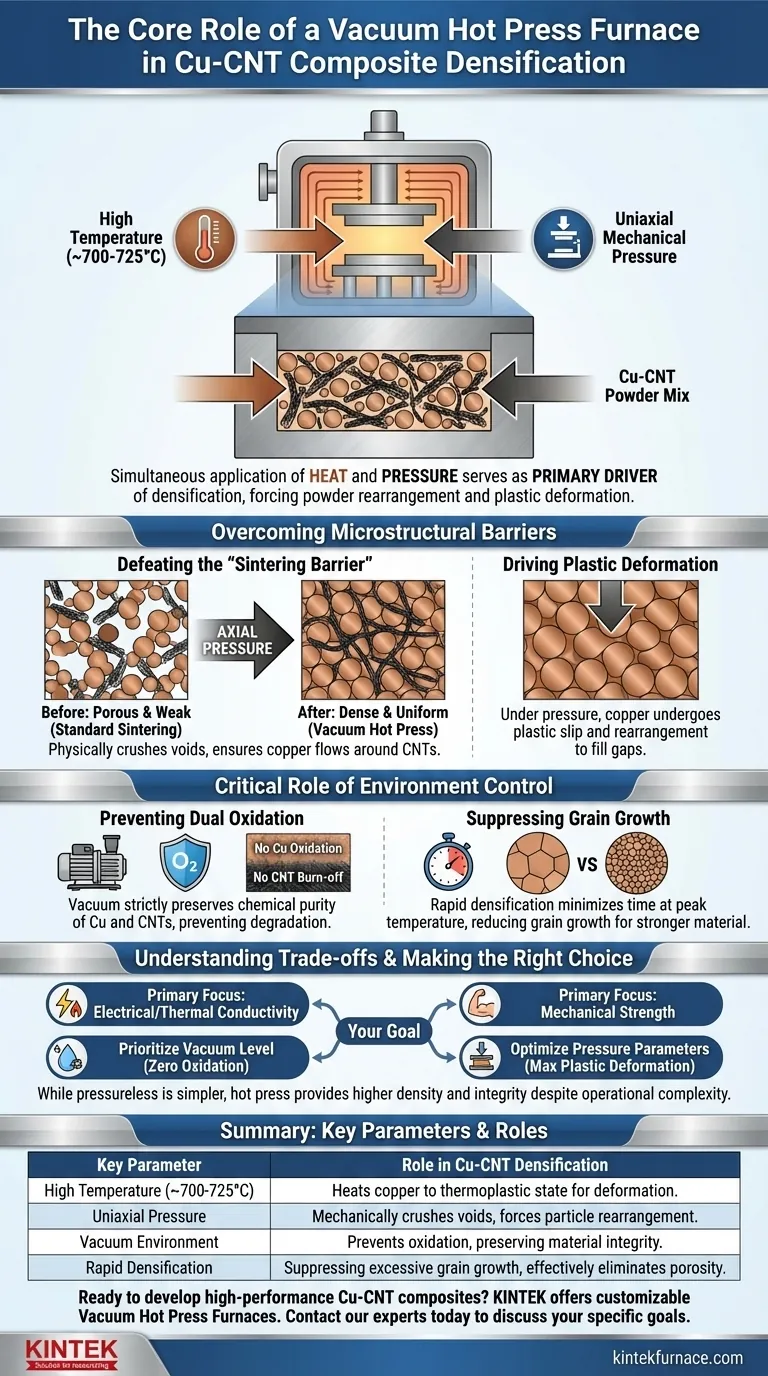

A vacuum hot press furnace serves as the primary driver of densification for copper-carbon nanotube (Cu-CNT) composites by simultaneously applying high heat (approximately 700-725°C) and uniaxial mechanical pressure. This dual-action approach physically forces powder particles to rearrange and undergo plastic deformation, overcoming the natural resistance to sintering created by carbon nanotubes to achieve near-theoretical density.

The core value of this equipment lies in its ability to mechanically eliminate porosity that temperature alone cannot resolve, while the vacuum environment strictly preserves the chemical purity of both the copper matrix and the carbon nanotubes.

Overcoming Microstructural Barriers

Defeating the "Sintering Barrier"

Carbon nanotubes are notoriously difficult to incorporate into metal matrices because they inhibit diffusion and create spacing between particles.

Standard pressureless sintering often fails to close these gaps, resulting in a porous, weak material. The vacuum hot press furnace overcomes this by applying axial mechanical pressure. This force physically crushes the voids and ensures the copper matrix flows around the nanotubes.

Driving Plastic Deformation

The furnace operates by heating the copper to a thermoplastic state.

Under the influence of the applied pressure, the copper particles undergo plastic slip and rearrangement. This mechanism forces the material to fill interstitial spaces, resulting in a dense, uniform structure that is difficult to achieve through diffusion mechanisms alone.

The Critical Role of Environment Control

Preventing Dual Oxidation

The "vacuum" component of the furnace is as critical as the pressure. Copper oxidizes readily at high temperatures, which degrades electrical and thermal conductivity.

Furthermore, carbon nanotubes can degrade or burn away in the presence of oxygen. The high-vacuum environment ensures that neither the matrix nor the reinforcement oxidizes during the heating process, maintaining the integrity of the composite.

Suppressing Grain Growth

Achieving high density often requires high heat, which can lead to excessive grain growth—a side effect that weakens the material.

The hot press method facilitates rapid densification. Because the pressure aids densification so effectively, the material spends less time at peak temperatures compared to conventional methods. This effectively suppresses excessive grain growth while still eliminating pores.

Understanding the Trade-offs

Equipment Complexity vs. Material Quality

While pressureless sintering is simpler, it creates composites with lower density and structural integrity.

The trade-off here is operational complexity for performance. You are exchanging a simple firing process for a system that must manage hydraulics, vacuum integrity, and precise thermal profiles simultaneously. This is necessary because Cu-CNT composites possess high inter-particle friction and covalent bonding characteristics that simple heating cannot overcome.

Limitations of Uniaxial Pressure

It is important to note that hot pressing typically applies pressure in one direction (uniaxial).

While this is excellent for flat plates or simple shapes, it forces particle rearrangement primarily in the direction of the force. For highly complex geometries, this can present challenges compared to isostatic pressing methods, though it remains superior for producing dense bulk billets.

Making the Right Choice for Your Goal

To maximize the utility of a vacuum hot press furnace for your Cu-CNT project, consider your primary performance metrics:

- If your primary focus is Electrical/Thermal Conductivity: Prioritize the vacuum level to ensure zero oxidation of the copper matrix, as oxides act as insulators.

- If your primary focus is Mechanical Strength: Focus on the optimization of the pressure parameters (e.g., 700-725°C range) to maximize plastic deformation and reach theoretical density limits.

Ultimately, the vacuum hot press furnace is not just a heating element; it is a mechanical forming tool essential for forcing reluctant materials into a unified, high-performance composite.

Summary Table:

| Key Parameter | Role in Cu-CNT Densification |

|---|---|

| High Temperature (~700-725°C) | Heats copper to a thermoplastic state for deformation. |

| Uniaxial Pressure | Mechanically crushes voids, forces particle rearrangement and plastic flow. |

| Vacuum Environment | Prevents oxidation of copper and carbon nanotubes, preserving material integrity. |

| Rapid Densification | Suppresses excessive grain growth while effectively eliminating porosity. |

Ready to develop high-performance copper-carbon nanotube composites?

Backed by expert R&D and manufacturing, KINTEK offers a range of customizable Vacuum Hot Press Furnaces designed to overcome the sintering barriers of advanced materials like Cu-CNTs. Our systems ensure the precise control of temperature, pressure, and vacuum environment critical for achieving maximum density, conductivity, and strength.

Contact our experts today to discuss how a KINTEK vacuum hot press furnace can be tailored to your specific research and production goals.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a hot press sintering furnace play in Cf-UHTC production? Achieve Peak Density in Refractory Composites

- What are the core advantages of high-vacuum hot press sintering for Al2O3/TiC ceramics? Achieve Near-Theoretical Density

- What role does a vacuum hot press sintering furnace play in Ti/Al2O3 processing? Achieve 99% Density

- What are the advantages of using a VHP furnace over CVD for ZnS? Boost Strength and Efficiency with Vacuum Hot Pressing

- What are the advantages of using a Spark Plasma Sintering (SPS) system for UHTCs? Master Rapid Densification

- What is activated hot sintering and its advantages? Achieve Superior Material Densification Efficiently

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- Why is a high vacuum environment necessary in a Vacuum Hot Pressing (VHP) furnace for preparing magnesium alloy composites? Prevent Oxidation and Maximize Performance