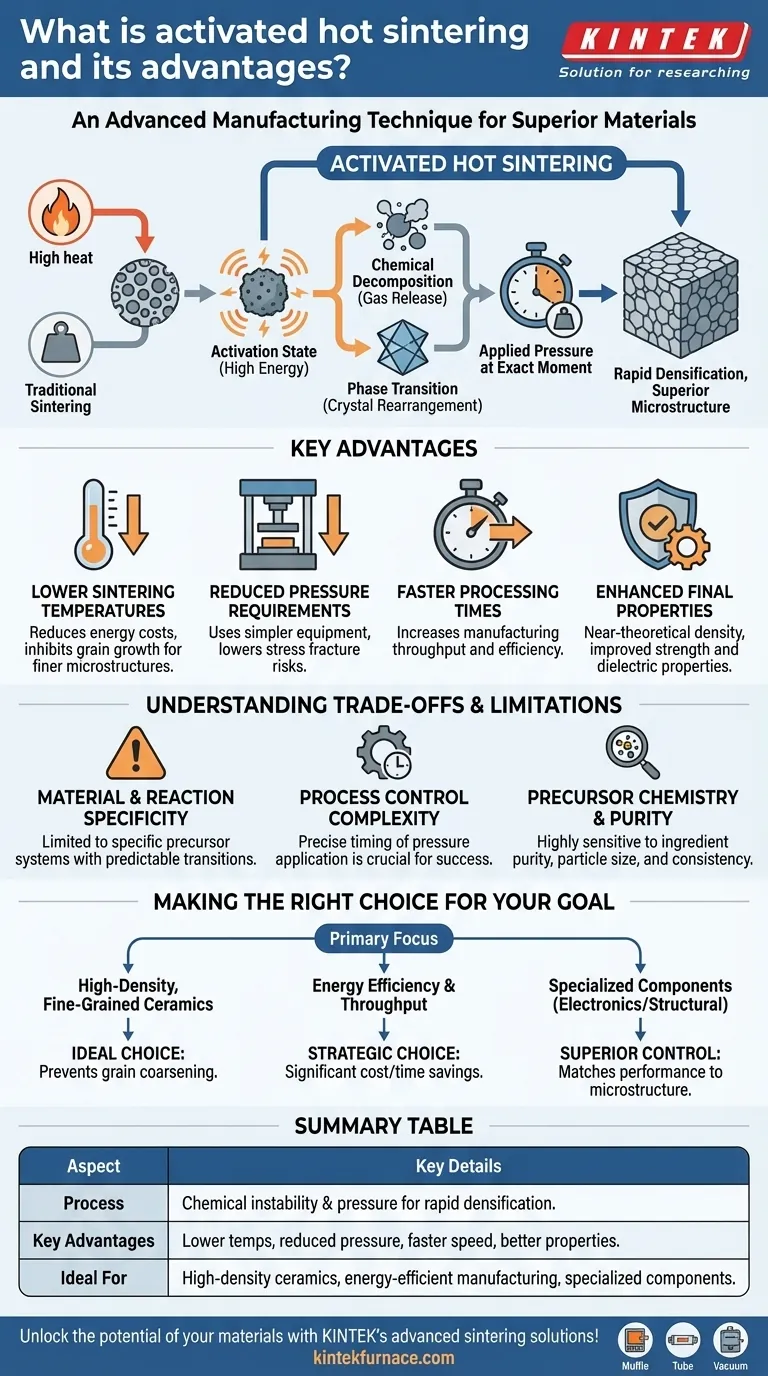

At its core, Activated Hot Sintering is an advanced manufacturing technique that harnesses a material's own chemical instability to achieve densification. It strategically applies pressure during a phase transition or chemical decomposition, a moment when the material is in a temporary, high-energy "activated" state, allowing for the rapid formation of dense solids at significantly lower temperatures and pressures than traditional methods.

The true advantage of this method is not just energy savings; it is about using precise chemical timing to create superior materials. By leveraging a material's fleeting reactive state, it enables the production of high-density components with finer microstructures that are often impossible to achieve with conventional high-temperature firing.

The Principle Behind "Activation"

What is Sintering?

Sintering is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction. In traditional methods, immense heat and pressure are required to force solid particles to bond and reduce the empty space between them.

The Role of High-Energy States

"Activation" refers to the process of putting the material into a highly reactive state just before or during compaction. This is typically achieved in two ways:

- Chemical Decomposition: Using a precursor compound (like a metal hydroxide) that breaks down when heated, releasing gas and leaving behind a new, highly reactive oxide.

- Phase Transition: Heating a material to a point where its internal crystal structure rearranges, which creates transient surface energy and defects that promote bonding.

How Activation Aids Densification

The freshly formed surfaces and structural defects present during these "activated" moments are extremely unstable and possess high surface energy. The atoms are much more mobile and eager to bond with neighboring particles to reach a more stable, lower-energy state.

By applying pressure at this exact moment, the densification process is dramatically accelerated. It requires far less external energy (heat and pressure) to eliminate porosity and achieve a dense final product.

Key Advantages Over Traditional Methods

Lower Sintering Temperatures

This is the most significant benefit. Operating at lower temperatures drastically reduces energy consumption and operational costs. Crucially, it also inhibits unwanted grain growth, which allows for a final product with a finer, more uniform microstructure and superior mechanical properties.

Reduced Pressure Requirements

Because the material is chemically primed to densify, the amount of external pressure needed is much lower. This allows for the use of simpler, less expensive, and less massive hot-pressing equipment. It also reduces the risk of introducing stress fractures into the final component.

Faster Processing Times

The high reactivity of the activated powder means the entire densification process can be completed in a much shorter time frame. This increases manufacturing throughput and efficiency.

Enhanced Final Properties

The combination of low temperature and controlled pressure typically results in ceramics with near-theoretical density and exceptionally fine grain structures. This directly translates to improved performance, such as higher strength in structural ceramics or better dielectric properties in electronic components like barium titanate.

Understanding the Trade-offs and Limitations

Material and Reaction Specificity

Activated Hot Sintering is not a universal solution. Its success hinges entirely on having a suitable precursor material that undergoes a predictable and useful decomposition or phase transition at a workable temperature. This limits its application to specific material systems.

Process Control Complexity

Timing is everything. The pressure must be applied in precise synchronization with the chemical reaction. If pressure is applied too early or too late, the benefits are lost. If a decomposition reaction releases gas too quickly, it can create pores and defects, undermining the goal of achieving high density.

Precursor Chemistry and Purity

The final product is only as good as the starting ingredients. This method is highly sensitive to the purity, particle size, and chemical consistency of the precursor powders. Impurities can cause unpredictable reactions and compromise the final material properties.

Making the Right Choice for Your Goal

Activated Hot Sintering is a strategic choice for producing advanced materials where microstructure control is paramount.

- If your primary focus is producing high-density, fine-grained ceramics: This method is ideal, as the lower temperatures inherently prevent the grain coarsening that plagues high-temperature processes.

- If your primary focus is energy efficiency and throughput: This process offers significant cost and time savings over traditional hot pressing, provided a suitable precursor chemistry exists for your material.

- If your primary focus is fabricating specialized components: For advanced electronic or structural materials where performance is directly tied to microstructure, this technique provides a level of control that is difficult to match.

Ultimately, adopting this technique is a calculated decision to trade material selection flexibility for exceptional control over the final product's density and structure.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Uses chemical instability during phase transition/decomposition for rapid densification under pressure. |

| Key Advantages | Lower temperatures, reduced pressure, faster processing, finer microstructures, and improved material properties. |

| Limitations | Material-specific, requires precise timing and pure precursors; not universally applicable. |

| Ideal For | High-density ceramics, energy-efficient manufacturing, and specialized components in electronics/structural applications. |

Unlock the potential of your materials with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, helping you achieve superior densification and efficiency. Ready to enhance your process? Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results

- What is a hot press used for? Fabricate Dense, High-Performance Materials