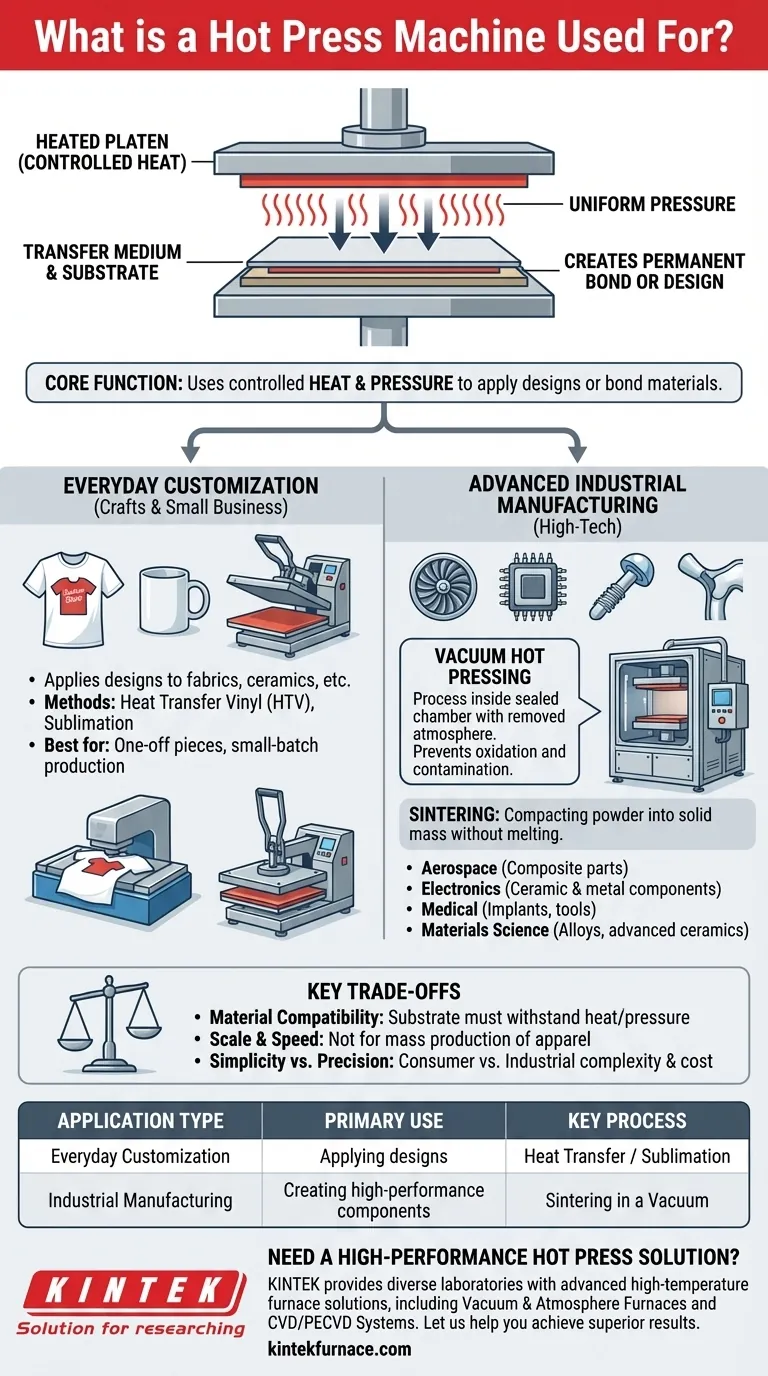

In essence, a hot press is a machine that uses controlled heat and pressure to apply a design or bond materials together. It works by pressing a heated plate (platen) onto a transfer medium and a substrate, causing a physical or chemical change that makes the application permanent. This process is used for everything from printing custom t-shirts to manufacturing high-performance components for the aerospace industry.

A hot press is not just a single tool but a category of technology. Its core function—combining heat and pressure—is fundamental to both simple craft personalization and advanced industrial manufacturing, with the specific application depending entirely on the materials and environment involved.

The Core Principle: How Heat and Pressure Transform Materials

At its heart, a hot press is a simple concept. It precisely controls two key variables—temperature and force—to achieve a desired outcome on a material, known as the substrate.

The Role of Controlled Heat

The top platen of the machine heats to a specific, uniform temperature. This heat is critical for activating thermal adhesives, curing inks, or initiating the process of sublimation, where solid dye turns into a gas to permeate the substrate's surface.

The Function of Uniform Pressure

Simultaneously, the machine applies even pressure across the entire surface. This pressure ensures firm contact between the transfer material and the substrate, allowing the heat to work effectively and creating a durable, permanent bond without gaps or weak spots.

Two Worlds of Application: From Crafts to High-Tech

The term "hot press" covers a wide spectrum of machinery, from simple tabletop devices to massive industrial systems. The application dictates the complexity of the machine.

Everyday Customization: Heat Transfer and Sublimation

For hobbyists and small businesses, a standard heat press is a cornerstone tool. It is primarily used for applying designs to fabrics, ceramics, and other items. Common methods include using Heat Transfer Vinyl (HTV) or sublimation prints to create custom apparel, mugs, and promotional goods.

Advanced Industrial Manufacturing: Vacuum Hot Pressing

In high-tech fields, a far more advanced version called a vacuum hot press is used. This process takes place inside a sealed chamber where the atmosphere is removed. The vacuum prevents oxidation and contamination, which is critical when working with reactive or high-purity materials.

This technique is essential for sintering, a process that uses heat and pressure to compact and form a solid mass of material from powder without melting it to the point of liquefaction.

Industrial Use-Cases

Vacuum hot pressing is vital for creating components with superior strength, thermal, and electrical properties. Key sectors include:

- Aerospace: Fabricating lightweight, high-strength composite parts.

- Electronics: Creating specialized ceramic and metal components.

- Medical: Manufacturing biocompatible implants and surgical tools from advanced materials.

- Materials Science: Producing industrial ceramics, refractory metals, and new alloys through powder metallurgy.

Understanding the Key Trade-offs

While versatile, the hot press process has specific constraints you must understand before committing to it for a project.

Material Compatibility is Crucial

The single biggest limitation is the substrate's ability to withstand heat and pressure. The process is not suitable for materials that will melt, deform, or be damaged by high temperatures.

Scale and Speed Considerations

A standard heat press is best suited for one-off pieces or small-batch production. For true mass production of items like apparel, other methods such as screen printing are often faster and more cost-effective.

Simplicity vs. Industrial Precision

There is a vast difference in complexity and cost. A consumer-grade heat press for t-shirts is relatively simple and affordable. An industrial vacuum hot press is a highly complex, expensive piece of capital equipment requiring specialized knowledge to operate.

Making the Right Choice for Your Goal

To determine if a hot press is the right tool, you must first define your objective.

- If your primary focus is custom apparel, gifts, and promotional items: A standard heat press is the ideal and most accessible tool for applying designs with heat transfer vinyl or sublimation.

- If your primary focus is manufacturing high-performance industrial components: A vacuum hot press is an essential technology for creating advanced ceramics, composites, and metal alloys for critical applications.

Ultimately, the hot press is a powerful tool whose value lies in its remarkable versatility across different scales of production.

Summary Table:

| Application Type | Primary Use | Key Process |

|---|---|---|

| Everyday Customization | Applying designs to fabrics, mugs, etc. | Heat Transfer, Sublimation |

| Industrial Manufacturing | Creating high-performance components | Sintering in a Vacuum |

Need a High-Performance Hot Press Solution?

Whether your project involves custom material bonding or advanced industrial sintering, KINTEK's expertise is your key to success. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let us help you achieve superior results. Contact our experts today to discuss your specific application and discover the perfect hot press solution for your needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does automation enhance the hot pressing process? Boost Precision, Efficiency, and Quality

- What other types of furnaces are related to hot pressing? Explore Key Thermal Processing Technologies

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength

- What are the applications of hot pressing? Achieve Maximum Material Performance