In short, automation enhances the hot pressing process by introducing precise, repeatable control over every critical variable, from temperature and pressure to cycle timing. This systematic approach drastically reduces human error, minimizes material waste, and ensures a consistently high-quality output that is difficult to achieve with manual operation.

The core value of automation in hot pressing is not just about speed; it's about transforming the process from an operator-dependent art into a data-driven science. This ensures that every part produced meets exact specifications, every time.

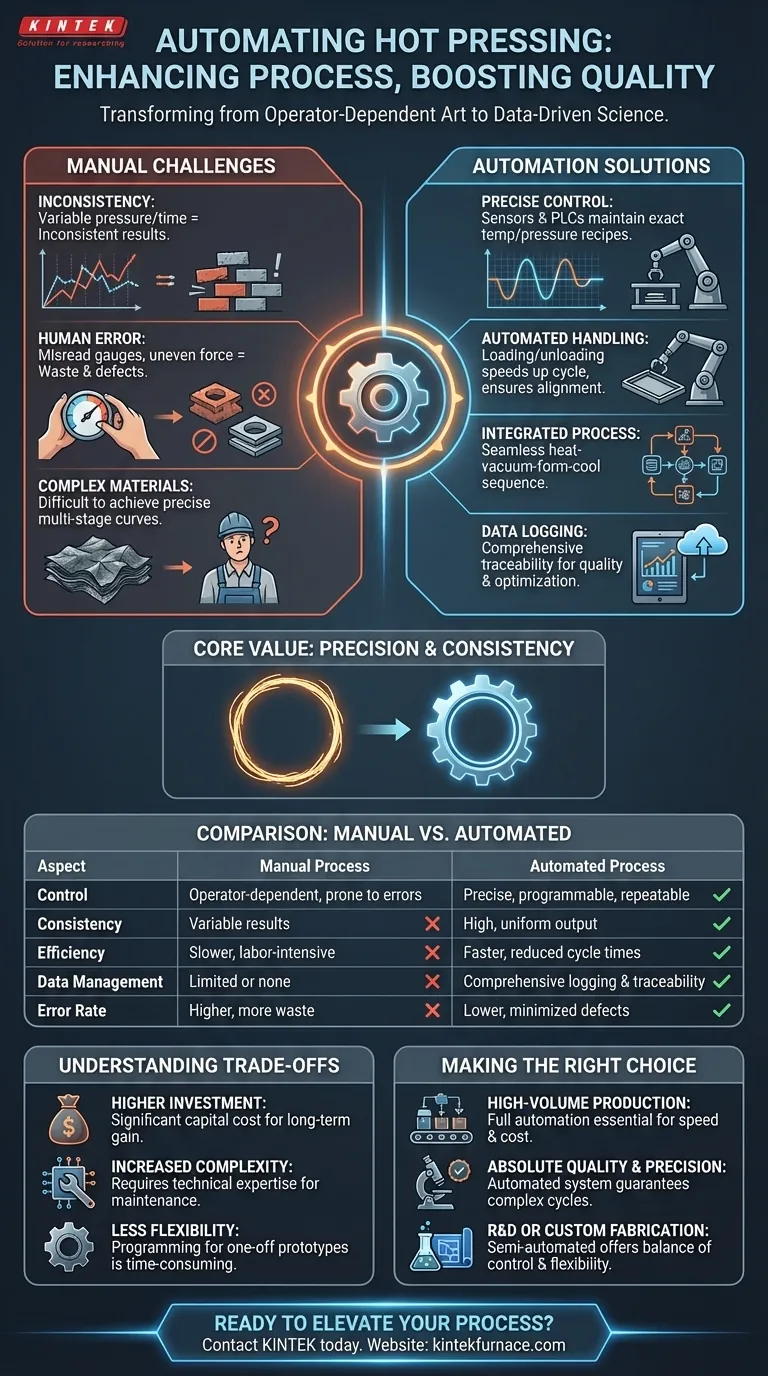

Why Manual Control Falls Short

To understand the impact of automation, we must first acknowledge the inherent limitations of manual hot pressing. The process relies on a delicate balance of heat, pressure, and time.

The Problem of Inconsistency

Manual adjustments by an operator, no matter how skilled, are susceptible to small variations. These slight differences in pressure application or timing can lead to inconsistent product density, surface finish, and structural integrity.

The Risk of Human Error

Operators can misread gauges, apply pressure unevenly, or misjudge timing. These errors can result in rejected parts, wasted material, and lost production time, directly impacting profitability.

The Challenge of Complex Materials

Modern manufacturing often involves advanced composites and polymers that require extremely precise heating and pressure curves. Achieving these complex multi-stage cycles manually is impractical and unreliable.

How Automation Delivers Precision and Efficiency

Automation addresses these challenges by integrating control over the entire hot pressing workflow. It systematizes each step for optimal and repeatable results.

Precise Temperature and Pressure Control

Automated systems use sensors and programmable logic controllers (PLCs) to maintain the exact temperature and pressure required for a specific material. The system can execute pre-programmed recipes, guaranteeing that the ideal conditions are met for every cycle.

Automated Material Handling

Modern presses automate tasks like loading raw materials (table feeding) and unloading finished parts (demolding). This not only speeds up the cycle but also ensures materials are positioned correctly, preventing defects caused by misalignment.

Integrated Process Steps

Automation seamlessly combines heating, vacuuming (to remove trapped air and volatiles), forming, and cooling into one continuous, optimized sequence. This eliminates the delays and potential errors that occur when moving between manual stations.

Data Logging and Traceability

An automated system logs the exact parameters used for every part produced. This data is invaluable for quality control, process optimization, and providing traceability for industries like aerospace or medical manufacturing where it is a requirement.

Understanding the Trade-offs

While the benefits are significant, adopting automation is a strategic decision with clear trade-offs that must be considered.

Higher Initial Investment

Fully automated hot press systems represent a significant capital expenditure compared to simpler, manual equipment. The return on this investment must be calculated based on expected gains in quality, throughput, and reduced labor costs.

Increased Complexity and Maintenance

Automated systems incorporate sophisticated electronics, sensors, and software. This requires a higher level of technical expertise for maintenance and troubleshooting. A machine failure can cause more significant downtime if in-house expertise is not available.

Less Flexibility for One-Off Prototypes

Programming an automated press for a complex, one-off part can be time-consuming. For rapid, low-fidelity prototyping, a manual press can sometimes offer more immediate flexibility, though with less precision.

Making the Right Choice for Your Goal

Your decision to leverage automation should be driven by your primary manufacturing objective.

- If your primary focus is high-volume production: Full automation is essential for achieving the speed, consistency, and low per-unit cost required to be competitive.

- If your primary focus is absolute quality and precision: An automated system is the only way to guarantee that complex curing cycles for advanced materials are executed perfectly every time.

- If your primary focus is R&D or custom fabrication: A semi-automated system may offer the best balance, providing precise control over key variables while retaining flexibility for frequent changes.

By removing variability and implementing precise control, automation empowers you to achieve predictable, high-quality results at scale.

Summary Table:

| Aspect | Manual Process | Automated Process |

|---|---|---|

| Control | Operator-dependent, prone to errors | Precise, programmable, repeatable |

| Consistency | Variable results | High, uniform output |

| Efficiency | Slower, labor-intensive | Faster, reduced cycle times |

| Data Management | Limited or none | Comprehensive logging and traceability |

| Material Handling | Manual, risk of misalignment | Automated, precise positioning |

| Error Rate | Higher, more waste | Lower, minimized defects |

Ready to elevate your hot pressing with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental and production requirements. Whether you're in high-volume manufacturing, R&D, or custom fabrication, our automated systems ensure consistent quality and reduced costs. Contact us today to discuss how we can enhance your process!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What are the typical operational steps when using a vacuum press? Master Flawless Bonding and Forming

- What role do vacuum hot press furnaces play in research and development laboratories? Unlock Next-Gen Material Innovations

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What are the benefits of the vacuum environment system in a vacuum hot press furnace? Unlock High-Density Sintering

- What role do graphite molds play in ZnS vacuum hot pressing? Optimize Densification and Optical Purity

- What components are used in hot press furnaces to apply pressure? Essential Parts for Precise High-Temp Compression

- How does the axial pressure applied by a vacuum hot pressing sintering furnace contribute to material densification?