In essence, integrating a vacuum into the hot-pressing process fundamentally alters the manufacturing environment by removing atmospheric gases. This seemingly simple change prevents unwanted chemical reactions like oxidation and allows materials to be processed at higher temperatures without vaporizing, enabling the creation of denser, purer, and stronger final components.

The core challenge in advanced material processing is achieving full densification and absolute purity. Using a vacuum is the key solution, as it removes atmospheric interference, allowing for cleaner sintering and consolidation at temperatures and pressures that would be impossible under normal conditions.

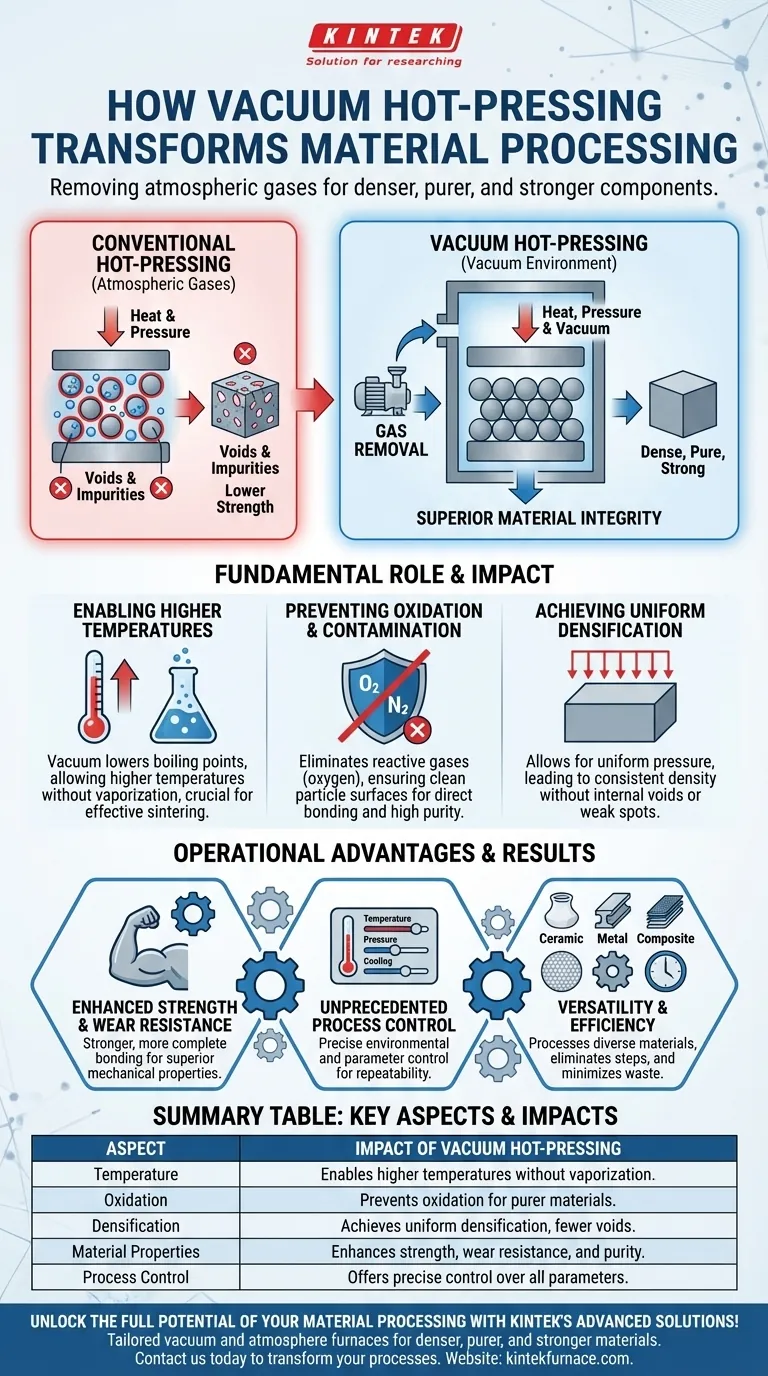

The Fundamental Role of Vacuum in Hot-Pressing

To understand the impact of vacuum hot-pressing, we must look at how it changes the physics and chemistry of the process. It's not just about removing air; it's about creating a new set of rules for how materials behave under heat and pressure.

Enabling Higher Processing Temperatures

At normal atmospheric pressure, many materials will vaporize or decompose before they reach a temperature suitable for effective sintering.

A vacuum lowers the boiling point of materials. This allows the furnace to reach much higher temperatures, causing the material to slightly melt and densify under pressure without being lost to vaporization.

This controlled, high-temperature environment is crucial for facilitating the sintering process, where individual particles fuse together to form a solid, dense mass.

Preventing Oxidation and Contamination

One of the most significant advantages of a vacuum environment is the elimination of reactive gases, primarily oxygen.

Without oxygen, oxidation is completely prevented. This ensures that the surfaces of the material particles are clean and can bond directly with each other, which is critical for achieving high strength.

This creates a clean, impurity-free environment that is essential for producing high-quality, ultra-clean components for sensitive applications in aerospace, medical, and electronics.

Achieving Uniform Densification

The combination of a clean particle surface and precise pressure control leads to more consistent results.

A vacuum furnace allows for uniform pressure distribution across the component. This, combined with the lack of surface contaminants, ensures that the material densifies evenly without internal voids or weak spots.

The result is a final product with highly consistent and predictable mechanical properties throughout its structure.

The Impact on Final Material Properties

The controlled environment of a vacuum hot press directly translates into superior material characteristics that are often unattainable with conventional methods.

Enhanced Strength and Wear Resistance

By creating a stronger, more complete bond between material particles, the process yields components with significantly higher strength and wear resistance.

This improvement reduces the need for secondary hardening or coating processes, streamlining the manufacturing workflow.

Superior Purity and Integrity

The absence of atmospheric contamination means the final material is chemically purer.

This is especially critical for reactive metals, advanced ceramics, and alloys where even trace amounts of oxygen or nitrogen can dramatically degrade performance.

Unlocking Advanced Material Formulations

The precision of vacuum hot-pressing opens the door to creating novel materials.

It provides the versatility to process a wide range of materials, including metals, alloys, ceramics, composites, and magnetic materials, each with its own unique processing requirements.

Understanding the Operational Advantages

Beyond the material itself, implementing vacuum hot-pressing offers significant benefits to the manufacturing operation as a whole.

Unprecedented Process Control

Modern vacuum furnaces offer exceptional and precise control over temperature, pressure, and cooling rates.

This allows engineers to fine-tune the process for a specific material or desired outcome, ensuring repeatability and quality from batch to batch.

Improved Efficiency and Cost-Effectiveness

While the initial investment can be higher, vacuum hot-pressing often leads to long-term savings.

It can eliminate the need for additional processing steps, such as post-sintering cleanup or machining to remove surface defects. This is especially true for small or complex parts where it also minimizes material waste.

Versatility Across Applications

The technology is not limited to a single function. It is used for a variety of thermal processes.

Key applications include sintering, thermoforming of composites, and the hot vacuum pressing of multi-layer materials, making it a flexible asset in an advanced manufacturing facility.

Making the Right Choice for Your Goal

To apply this understanding, consider your primary objective for the material you are processing.

- If your primary focus is material purity and peak performance: The key benefit is the elimination of contamination, which directly leads to superior mechanical properties and chemical integrity.

- If your primary focus is manufacturing complex or sensitive components: Vacuum provides the precise environmental control and uniform pressure needed to produce intricate parts with minimal waste and high consistency.

- If your primary focus is overall process efficiency: Vacuum hot-pressing can reduce total manufacturing costs by consolidating process steps and improving the yield of high-quality, finished parts.

Ultimately, integrating a vacuum into your hot-pressing process is the definitive step toward achieving maximum material integrity and process control.

Summary Table:

| Key Aspect | Impact of Vacuum Hot-Pressing |

|---|---|

| Temperature | Enables higher processing temperatures without vaporization, facilitating sintering |

| Oxidation | Prevents oxidation and contamination for cleaner, purer materials |

| Densification | Achieves uniform densification with fewer voids and consistent properties |

| Material Properties | Enhances strength, wear resistance, and purity for superior performance |

| Process Control | Offers precise control over temperature, pressure, and cooling rates |

Unlock the full potential of your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored vacuum and atmosphere furnaces, including Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you achieve denser, purer, and stronger materials with enhanced efficiency. Contact us today to discuss how our solutions can transform your hot-pressing processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production