In composite material processing, vacuum pressing is primarily used for two key functions: consolidating multiple material layers into a unified laminate and shaping pre-heated composite sheets into complex forms. These applications, which include hot vacuum pressing, thermoforming, and vacuum forming, leverage vacuum not just as a mechanical force but as a way to control the material's chemical and physical environment during fabrication.

The true value of vacuum pressing extends beyond simply applying pressure. By creating a vacuum, you eliminate atmospheric interference, enabling uniform compaction, preventing oxidation at high temperatures, and fundamentally enhancing the final material's density and structural integrity.

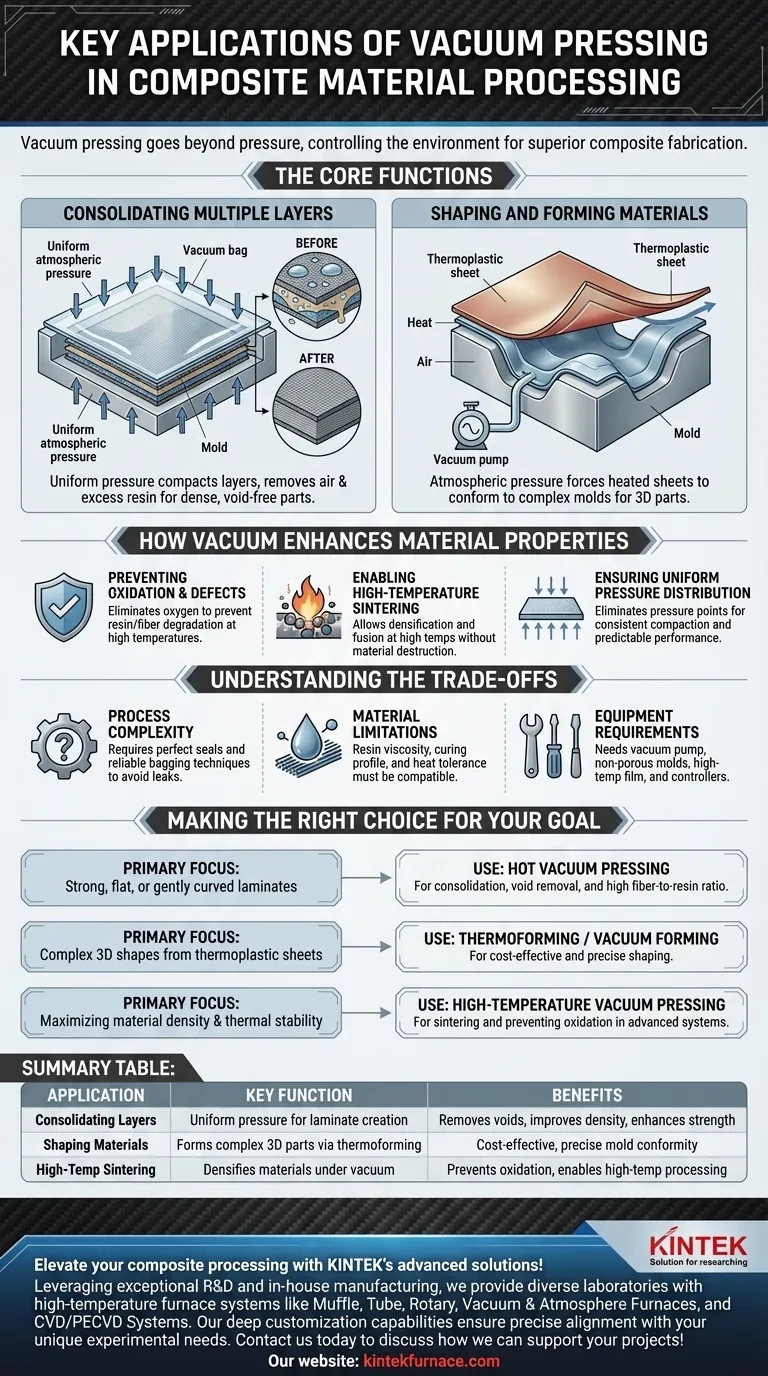

The Core Functions of Vacuum in Composite Processing

The term "vacuum pressing" describes several related techniques that use atmospheric pressure to achieve consolidation and shaping. The removal of air from a sealed bag or chamber creates a pressure differential, forcing the atmosphere to press down uniformly on the part inside.

Consolidating Multiple Layers

For creating composite laminates, multiple layers of fabric (like carbon fiber or fiberglass) and resin are placed in a stack. This stack is then sealed inside a vacuum bag.

When a vacuum is pulled, the atmospheric pressure outside the bag presses down evenly across the entire surface. This uniform pressure compacts the layers, squeezes out excess resin, and removes trapped air or volatile compounds, resulting in a dense, void-free part. This is often done with heat (hot vacuum pressing) to cure the resin simultaneously.

Shaping and Forming Materials

Vacuum is also central to thermoforming and vacuum forming. In these processes, a thermoplastic or pre-impregnated composite sheet is heated until it becomes pliable.

The softened sheet is then draped over a mold, and a vacuum is applied between the sheet and the mold surface. The atmospheric pressure forces the material to conform precisely to the mold's shape. This is an efficient way to create complex, three-dimensional parts like enclosures, fairings, or interior panels.

How Vacuum Enhances Material Properties

The use of a vacuum is not merely a clamping method; it fundamentally alters the processing environment to improve the final component's quality.

Preventing Oxidation and Defects

By removing air, vacuum pressing eliminates oxygen from the processing environment. This is critical when working at elevated temperatures, as it prevents oxidation of the resin and fibers, which would otherwise degrade the material's mechanical properties and surface finish.

Enabling High-Temperature Sintering

Certain advanced materials, including some composites and ceramics, require a process called sintering to achieve full density and strength. Sintering involves heating a material to just below its melting point, causing the particles to fuse together.

Using a vacuum allows materials to be heated to very high temperatures that would cause them to vaporize or decompose at normal atmospheric pressure. Under vacuum, the material can be heated, densified under pressure, and properly sintered without being destroyed.

Ensuring Uniform Pressure Distribution

Unlike a mechanical press that applies force at specific points, vacuum pressing uses atmospheric pressure that is perfectly distributed across every part of the component's surface. This eliminates pressure points and ensures consistent compaction and resin flow, which is critical for achieving predictable performance in the final part.

Understanding the Trade-offs

While powerful, vacuum-assisted processing requires careful control and carries specific considerations.

Process Complexity

Achieving a perfect vacuum seal is critical. Leaks can compromise pressure, introduce moisture, and lead to voids or other defects in the final part. This requires careful bagging techniques and reliable equipment.

Material Limitations

The process is most effective with specific resin systems and materials designed for it. The viscosity of the resin, its curing profile, and the material's ability to withstand the heat and pressure cycles must all be compatible with the chosen technique.

Equipment Requirements

Professional vacuum pressing requires an investment in equipment, including a reliable vacuum pump, non-porous molds, high-temperature bagging film, sealant tape, and accurate temperature controllers, especially for hot pressing applications.

Making the Right Choice for Your Goal

The specific vacuum technique you choose depends directly on your desired outcome.

- If your primary focus is creating strong, flat, or gently curved laminates: Use hot vacuum pressing to consolidate multiple layers, remove voids, and achieve a high fiber-to-resin ratio.

- If your primary focus is forming complex 3D shapes from thermoplastic sheets: Use thermoforming or vacuum forming for a cost-effective and repeatable shaping process.

- If your primary focus is maximizing material density and thermal stability: Leverage high-temperature vacuum pressing to enable sintering and prevent oxidation in advanced composite systems.

Ultimately, mastering vacuum pressing empowers you to create higher-quality composite parts by precisely controlling the forces and environment during fabrication.

Summary Table:

| Application | Key Function | Benefits |

|---|---|---|

| Consolidating Layers | Uniform pressure for laminate creation | Removes voids, improves density, enhances strength |

| Shaping Materials | Forms complex 3D parts via thermoforming | Cost-effective, precise mold conformity |

| High-Temperature Sintering | Densifies materials under vacuum | Prevents oxidation, enables high-temperature processing |

Elevate your composite processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, improving efficiency and material outcomes. Contact us today to discuss how we can support your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?