From a material quality standpoint, hot pressing creates exceptionally dense and pure components by simultaneously applying high temperature and pressure in a controlled, often vacuum, environment. This process fundamentally minimizes internal defects like porosity and prevents oxidation, resulting in a final material with significantly improved strength, hardness, and overall structural integrity.

The true advantage of hot pressing is not merely shaping a material, but re-engineering its internal microstructure. It eliminates the voids and impurities that act as failure points, allowing the material to achieve its maximum theoretical performance.

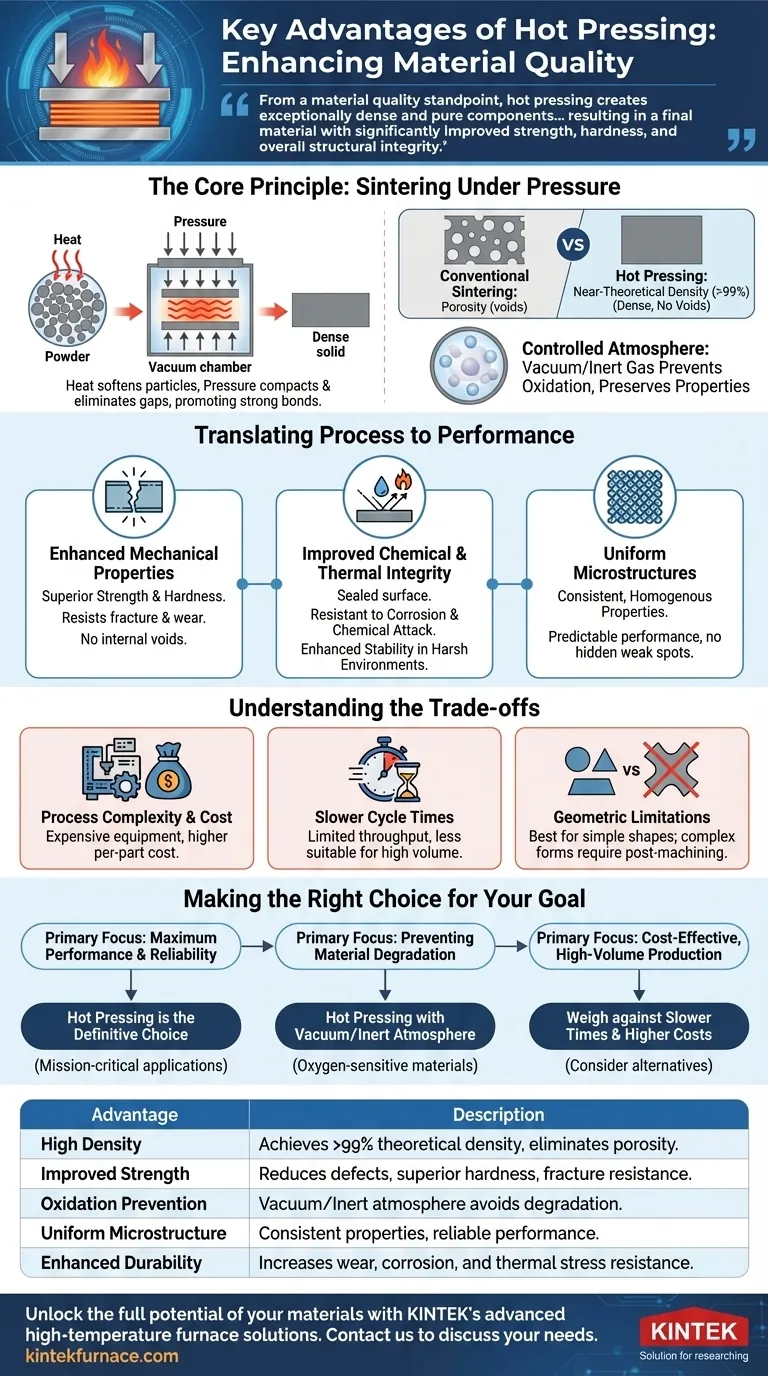

The Core Principle: Sintering Under Pressure

Hot pressing is an advanced manufacturing process that consolidates powders or pre-formed parts into a dense solid. It works by heating the material to a temperature where its particles become plastic, while simultaneously applying external pressure to force them together.

How Heat and Pressure Work Together

Heat provides the thermal energy needed to soften the material particles, increasing their atomic diffusion rate. Pressure then acts as the driving force, compacting the particles, eliminating gaps between them, and promoting strong, uniform bonds across the entire structure.

Achieving Near-Theoretical Density

The primary outcome of this combined action is the drastic reduction of porosity, or the tiny empty spaces within a material. By physically squeezing out these voids, hot pressing can achieve densities that are over 99% of the material's theoretical maximum. This lack of internal defects is critical for high-performance applications.

The Role of a Controlled Atmosphere

Most hot pressing is conducted in a vacuum or an inert gas atmosphere. This is a crucial detail, as it prevents the material from reacting with oxygen at high temperatures. The result is a component free from oxidation, which preserves the material's inherent properties and prevents the formation of brittle oxide layers.

Translating Process to Performance

The superior internal structure created by hot pressing directly translates into measurable improvements in the final component's performance characteristics.

Enhanced Mechanical Properties

A dense, non-porous microstructure provides exceptional strength and hardness. With no internal voids to act as stress concentration points, the material is far more resistant to fracture and deformation under load. This also leads to superior wear resistance.

Improved Chemical and Thermal Integrity

The low porosity achieved through hot pressing seals the material's surface and internal structure. This makes it significantly more resistant to corrosion and chemical attack, as there are fewer pathways for aggressive agents to penetrate the component. It also enhances thermal properties and stability in harsh environments.

Creating Uniform Microstructures

The combination of heat and pressure ensures that the densification process occurs evenly throughout the entire part. This results in a highly uniform and homogenous microstructure, which means the material's properties are consistent and predictable, with no hidden weak spots.

Understanding the Trade-offs

While hot pressing offers unparalleled quality, it is essential to understand its limitations to determine if it is the right process for your application.

Process Complexity and Cost

Hot press systems, which require vacuum furnaces and high-pressure hydraulic equipment, are complex and expensive to acquire and operate. This often translates to a higher per-part cost compared to simpler methods like conventional sintering.

Slower Cycle Times

Hot pressing is generally a slower, more deliberate process. The time required for heating, pressing, and cooling cycles can limit manufacturing throughput, making it less suitable for very high-volume production where speed is the primary driver.

Geometric Limitations

The process is best suited for producing parts with relatively simple geometries, such as discs, blocks, and cylinders. Complex, three-dimensional shapes can be difficult or impossible to press uniformly, which may require extensive post-process machining.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on your end goal. Hot pressing is a powerful tool when used for the right reasons.

- If your primary focus is maximum performance and reliability: Hot pressing is the definitive choice for creating materials with the lowest possible porosity and highest density, making it ideal for mission-critical applications.

- If your primary focus is preventing material degradation: The vacuum or inert atmosphere is essential for processing oxygen-sensitive materials like advanced ceramics, alloys, and composites.

- If your primary focus is cost-effective, high-volume production: You must weigh the superior quality of hot pressing against the higher costs and slower cycle times of alternatives like cold pressing and sintering.

Ultimately, choosing hot pressing is an investment in material integrity, ensuring your components perform without compromise.

Summary Table:

| Advantage | Description |

|---|---|

| High Density | Achieves over 99% theoretical density by eliminating porosity through combined heat and pressure. |

| Improved Strength | Reduces internal defects, leading to superior mechanical properties like hardness and fracture resistance. |

| Oxidation Prevention | Conducted in vacuum or inert atmospheres to avoid material degradation and brittleness. |

| Uniform Microstructure | Ensures consistent and homogenous material properties for reliable performance. |

| Enhanced Durability | Increases resistance to wear, corrosion, and thermal stress in harsh environments. |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision-engineered products like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior material quality. Contact us today to discuss how our hot pressing technologies can enhance your lab's performance and reliability!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What is a hot press used for? Fabricate Dense, High-Performance Materials