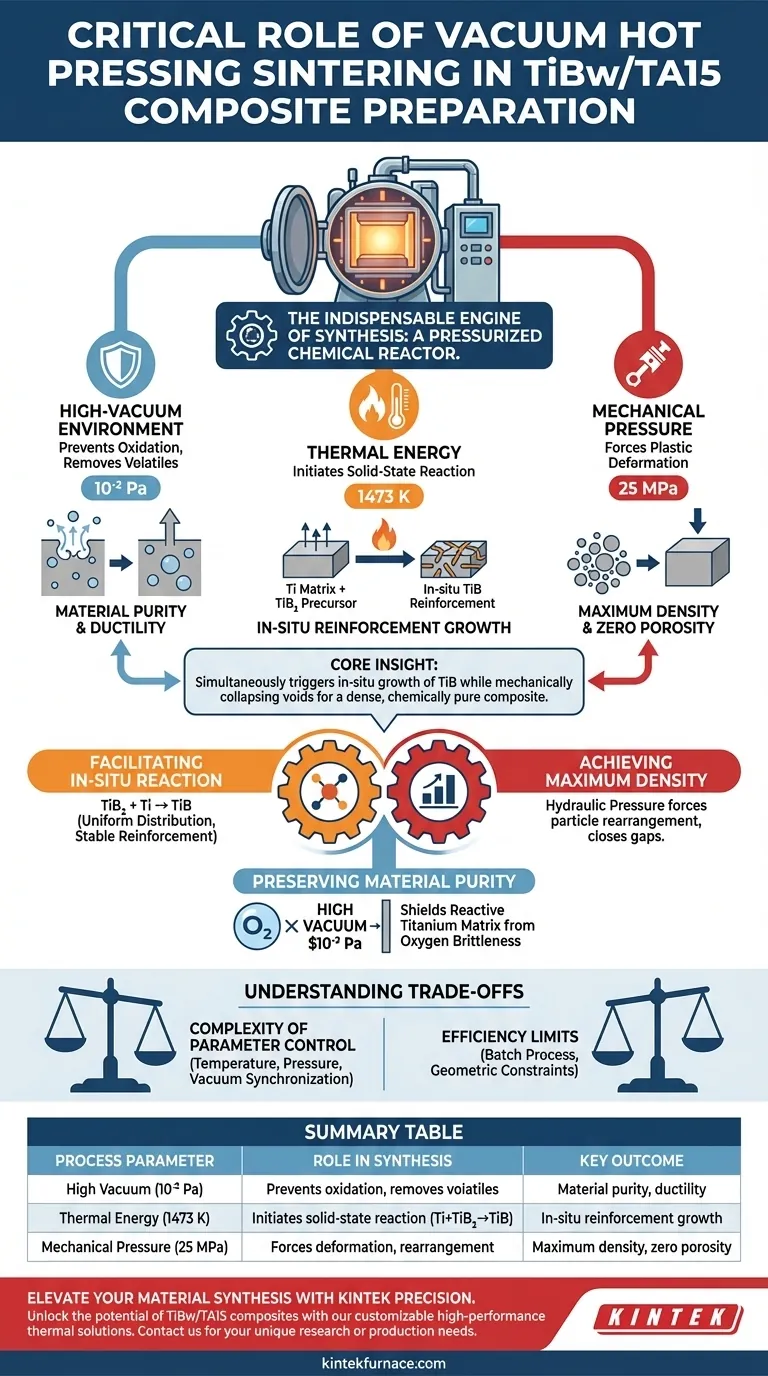

The vacuum hot pressing sintering furnace is the indispensable processing engine for creating in-situ synthesized TiBw/TA15 composites. It serves a triple function: it creates a high-vacuum environment (approx. $10^{-2}$ Pa) to prevent oxidation, applies thermal energy (1473 K) to drive chemical reactions, and exerts mechanical pressure (25 MPa) to force physical densification.

Core Insight: The furnace does not merely heat the material; it acts as a pressurized chemical reactor. Its primary value lies in its ability to simultaneously trigger the in-situ growth of TiB reinforcement phases while mechanically collapsing voids, ensuring the final composite is both chemically pure and structurally dense.

Facilitating the In-Situ Chemical Reaction

To create a high-performance TiBw/TA15 composite, you cannot simply mix ingredients; you must synthesize the reinforcement phase within the matrix.

Triggering the Transformation

The furnace provides the specific thermal conditions (e.g., 1473 K) required to initiate a solid-state reaction.

Under these conditions, the added $\text{TiB}_2$ reacts with the Titanium (Ti) matrix. This reaction transforms the precursors into the desired TiB reinforcement phase directly inside the material.

Uniform Distribution

Because this reaction occurs "in-situ" (in place) under heat and pressure, the resulting reinforcement phase is thermodynamically stable and chemically compatible with the matrix.

Achieving Maximum Density

A common failure mode in powder metallurgy is porosity—tiny air gaps that weaken the material. The vacuum hot pressing furnace solves this through mechanical force.

Mechanical Pore Elimination

While the material is hot and malleable, the furnace applies significant hydraulic pressure (e.g., 25 MPa).

This pressure forces the powder particles to rearrange and undergo plastic deformation. It physically closes the gaps between particles that thermal sintering alone might leave behind.

Ensuring Structural Integrity

By eliminating these pores, the process maximizes the relative density of the composite. This is critical for achieving the high strength and fatigue resistance required of TA15 titanium alloys.

Preserving Material Purity

Titanium alloys are notoriously reactive; they act as "oxygen sponges" at high temperatures, which destroys their ductility.

The Role of High Vacuum

The furnace maintains a high-vacuum environment ($10^{-2}$ Pa) throughout the heating cycle.

This effectively shields the Titanium matrix from oxidation. Without this vacuum, the titanium would react with atmospheric oxygen, leading to embrittlement and composite failure.

Removal of Volatiles

The vacuum also assists in evacuating any adsorbed gases trapped within the powder interstices before the pores are sealed by the pressure.

Understanding the Trade-offs

While vacuum hot pressing is superior for quality, it introduces specific constraints that must be managed.

Complexity of Parameter Control

Success relies on the precise synchronization of three variables: temperature, pressure, and vacuum level.

If pressure is applied too early (before adequate heating), particle bonding may be weak. If applied too late, the material may not densify fully.

Efficiency Limits

Unlike continuous sintering methods, vacuum hot pressing is typically a batch process.

It limits production speed and limits the geometric complexity of the parts produced, as the pressure is usually uniaxial (applied in one direction).

Making the Right Choice for Your Goal

When configuring your sintering process for TiBw/TA15, tailor your parameters to your specific performance requirements.

- If your primary focus is Mechanical Strength: Prioritize the pressure parameters (25 MPa) to ensure maximum pore elimination and the highest possible density.

- If your primary focus is Ductility and Purity: Focus on maintaining a rigorous vacuum level ($10^{-2}$ Pa) to prevent interstitial oxygen contamination that causes brittleness.

Summary: The vacuum hot pressing furnace is the critical link that translates raw powder and chemical potential into a dense, high-purity, and reinforced structural composite.

Summary Table:

| Process Parameter | Role in TiBw/TA15 Synthesis | Key Outcome |

|---|---|---|

| High Vacuum ($10^{-2}$ Pa) | Prevents oxidation and removes volatiles | Material purity and ductility |

| Thermal Energy (1473 K) | Initiates solid-state reaction (Ti + $\text{TiB}_2$ $\rightarrow$ TiB) | In-situ reinforcement growth |

| Mechanical Pressure (25 MPa) | Forces plastic deformation and particle rearrangement | Maximum density and zero porosity |

Elevate Your Material Synthesis with KINTEK Precision

Unlock the full potential of your TiBw/TA15 composites with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems—all fully customizable to meet your specific research or production requirements.

Whether you need to optimize mechanical strength through precise pressure control or preserve purity with high-vacuum environments, our team is ready to design the perfect furnace for your laboratory. Contact us today to discuss your unique needs and experience the KINTEK advantage in high-temperature engineering.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the advantages of benchtop SPS/FAST for titanium R&D? Accelerate Your Microstructural Engineering

- Why is a high vacuum essential for ZnS hot press sintering? Achieve Maximum Infrared Transmittance

- What are the core functions of graphite molds in the hot press sintering process of Nb-22.5Cr-5Si alloys? Find Out Now

- What are the technical advantages of Vacuum SPS systems for large transparent ceramics? Achieve Peak Optical Clarity

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength

- What role does a vacuum hot press furnace play in the densification of nanocomposites? Achieve Near-Theoretical Density

- What are the primary applications of vacuum press technology in metalworking? Achieve Precision in Aerospace, Automotive, and Electronics

- How does a vacuum hot press work? Unlock Superior Material Density and Purity