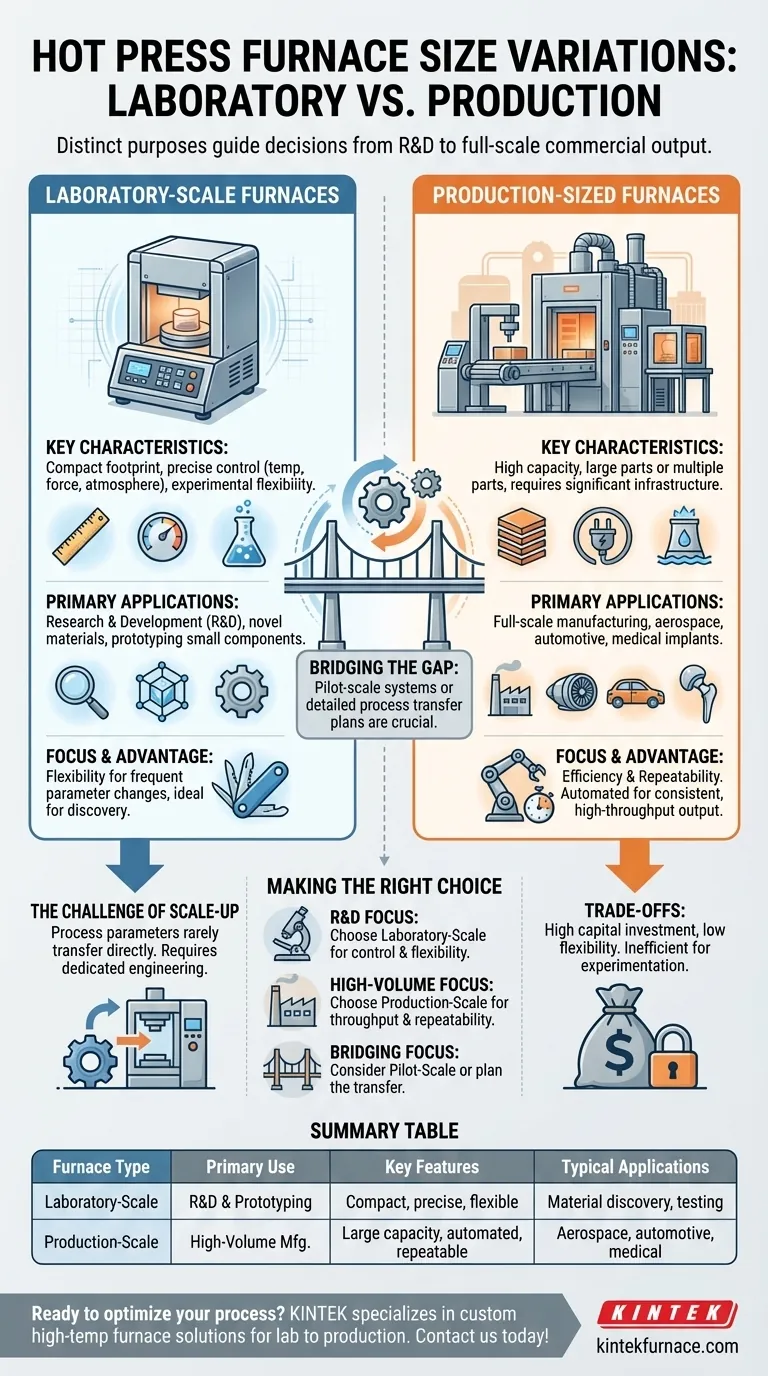

In essence, hot press furnaces are available in two primary size categories designed for distinct purposes. These range from smaller, versatile laboratory-sized units ideal for research and development to much larger production-sized furnaces built for high-volume manufacturing.

The distinction between laboratory and production furnaces is not merely about physical dimensions. It reflects a fundamental difference in purpose, guiding decisions from initial material discovery and process development to the demands of full-scale commercial output.

Understanding Laboratory-Scale Furnaces

Laboratory or "benchtop" hot press furnaces are the entry point into sintering and diffusion bonding. They are engineered for precision, control, and experimental flexibility.

Key Characteristics

These units are defined by their compact footprint, making them suitable for research environments where space is often limited. They typically process smaller samples, one at a time.

The core focus is on providing precise control over temperature, atmosphere, and pressing force. This allows researchers to meticulously study material behavior under specific conditions.

Primary Applications

Lab-scale furnaces are indispensable tools for research and development (R&D). Scientists use them to create novel materials, test new composite formulas, and develop new manufacturing processes.

They are also critical for prototyping small components and creating test coupons for mechanical or microstructural analysis before committing to larger-scale production.

The Advantage of Flexibility

The strength of a lab furnace lies in its versatility. It is designed for frequent changes in process parameters, materials, and sample geometries, making it the ideal platform for experimentation and discovery.

Scaling Up to Production-Sized Furnaces

Production hot presses are industrial workhorses, designed for repeatability, reliability, and high throughput. Their design philosophy prioritizes efficiency over experimental flexibility.

Key Characteristics

These are significantly larger, heavier systems requiring substantial floor space and dedicated facility infrastructure for power and cooling.

Their primary characteristic is high capacity. They can process much larger individual parts or multiple smaller parts simultaneously in a single cycle, maximizing output.

Primary Applications

Production furnaces are used in full-scale manufacturing environments. Industries like aerospace, defense, automotive, and medical implants rely on them to produce finished components.

The goal is to consistently manufacture parts that meet strict quality and performance specifications, often in a continuous or semi-continuous operation.

The Focus on Efficiency and Repeatability

In a production setting, repeatability is paramount. These furnaces are equipped with advanced automation and process controls to ensure every cycle is identical to the last.

This focus minimizes part-to-part variation and guarantees that the final products adhere to stringent industry standards.

Understanding the Trade-offs

Choosing a furnace size involves balancing capability with cost and operational complexity. The ideal choice for R&D is often inefficient for manufacturing, and vice versa.

Cost and Infrastructure

The capital investment for a production furnace is an order of magnitude higher than for a lab unit. Furthermore, its installation requires significant facility upgrades, including high-amperage electrical service, water cooling systems, and foundation reinforcement.

Operational Flexibility vs. Throughput

A lab furnace offers maximum flexibility to explore new ideas but has very low throughput. A production furnace delivers high throughput for a validated process but is extremely inefficient and costly to use for experimentation.

The Challenge of Process Transfer

A critical and often underestimated challenge is scaling a process developed on a lab unit to a production furnace. Differences in heating rates, thermal uniformity, and platen mechanics mean that parameters rarely transfer directly, requiring a dedicated process engineering effort.

Making the Right Choice for Your Goal

Your application and long-term objectives are the only factors that should guide your decision.

- If your primary focus is material discovery and R&D: A laboratory-scale furnace provides the essential control, precision, and flexibility for experimentation.

- If your primary focus is high-volume manufacturing: A production-sized furnace is necessary to achieve the required throughput, efficiency, and process repeatability.

- If your primary focus is bridging R&D with production: Consider a pilot-scale system or develop a clear engineering plan for transferring processes from a lab unit to a larger machine.

By aligning the furnace's capabilities with your specific goal, you ensure your investment serves as a powerful asset rather than an operational constraint.

Summary Table:

| Furnace Type | Primary Use | Key Features | Typical Applications |

|---|---|---|---|

| Laboratory-Scale | R&D and Prototyping | Compact, precise control, flexible | Material discovery, testing, small components |

| Production-Scale | High-Volume Manufacturing | Large capacity, automated, repeatable | Aerospace, automotive, medical implants |

Ready to optimize your sintering and diffusion bonding processes? KINTEK specializes in high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs—whether for lab research or full-scale production. Contact us today to discuss how our tailored hot press furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing