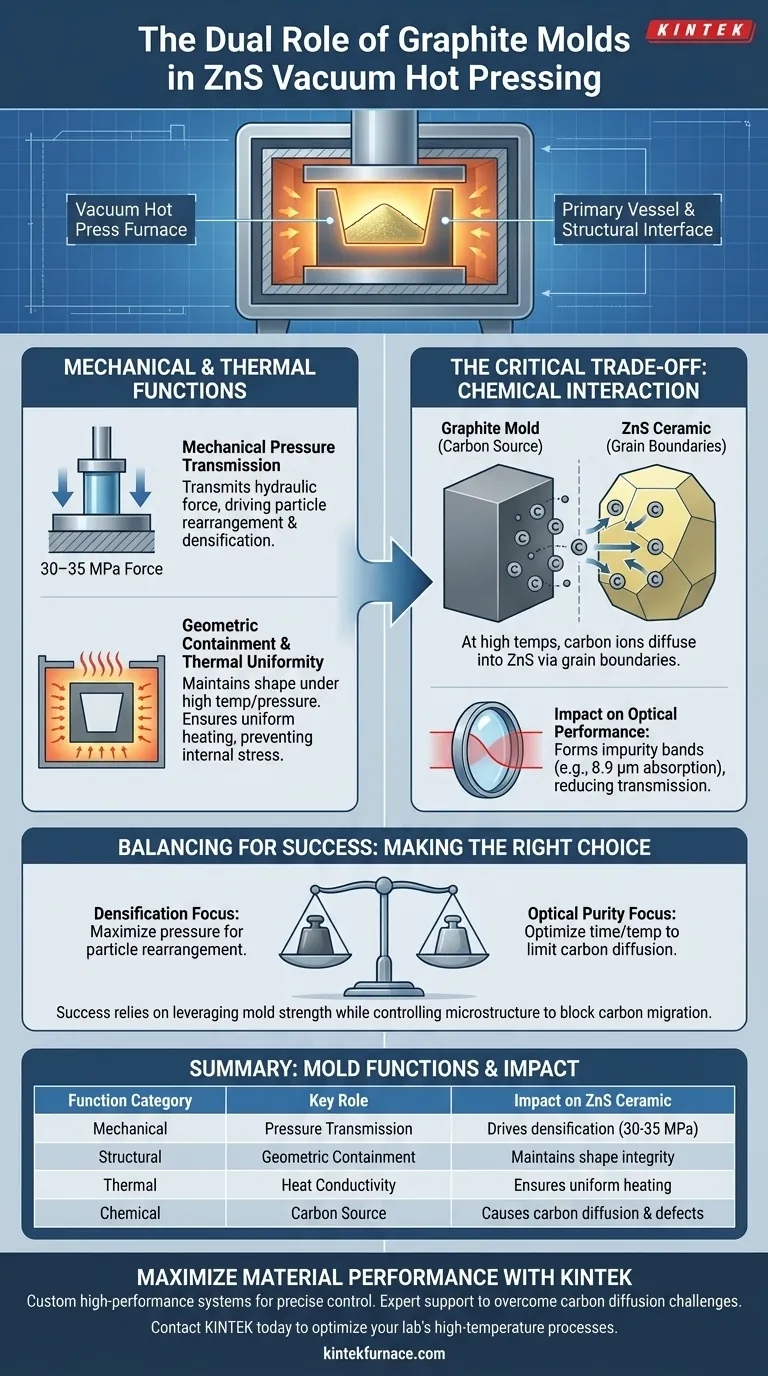

The graphite mold functions as the structural and mechanical interface during the vacuum hot pressing of Zinc Sulfide (ZnS). It serves as the primary vessel for shaping the ceramic powder while simultaneously acting as the essential medium for transmitting the extreme hydraulic pressure and heat required for densification.

The graphite mold is indispensable for converting hydraulic force into the mechanical pressure needed for sintering, yet it introduces a critical trade-off: at high temperatures, it acts as a carbon source that can diffuse into the ceramic, potentially compromising the material's optical purity.

Mechanical and Thermal Functions

The graphite mold is not merely a container; it is an active component in the sintering physics. Its role is defined by its ability to withstand extreme environments while facilitating the physical changes in the ZnS powder.

Mechanical Pressure Transmission

The primary function of the mold is to act as a transmission medium. It transfers the mechanical force generated by the hydraulic system directly to the ZnS powder.

This pressure (often reaching 30–35 MPa) is critical for pressure-assisted sintering. It forces particle rearrangement and plastic deformation, driving the material toward maximum density.

Geometric Containment and Shaping

The mold defines the physical dimensions of the final ceramic. It acts as a high-strength container that holds the loose powder in a specific geometry (the "green body").

It must maintain this structural integrity without deformation, even when subjected to uniaxial pressures and temperatures potentially exceeding 1800°C.

Thermal Conductivity and Uniformity

Graphite possesses excellent thermal conductivity. This property allows the mold to transfer heat efficiently from the furnace elements to the ZnS sample.

This ensures uniform heating throughout the ceramic body. Thermal uniformity is vital for preventing internal stress and ensuring consistent optical properties across the lens or window.

Understanding the Trade-offs: Chemical Interactions

While the mold is mechanically essential, its chemical interaction with ZnS at high temperatures presents a significant challenge. This section addresses the "Deep Need" regarding process control and quality assurance.

The Carbon Source Effect

At elevated sintering temperatures, the graphite mold effectively becomes a carbon source. Carbon ions can detach from the mold surface and migrate toward the ceramic material.

Grain Boundary Diffusion

These carbon ions diffuse into the ZnS ceramic primarily through grain boundaries. The boundaries act as pathways for impurities to penetrate the microstructure of the material.

Impact on Optical Performance

When carbon diffuses into the ZnS, it forms impurity bands or carbonate defects. Specifically, this interaction creates a distinct infrared absorption band at 8.9 μm.

This defect reduces the overall optical transmission and performance of the ceramic. Consequently, process control must focus on managing grain growth to reduce the volume of grain boundaries, thereby suppressing this diffusion effect.

Making the Right Choice for Your Goal

Balancing the mechanical necessity of the mold with its chemical risks is the key to successful ZnS sintering.

- If your primary focus is Densification: Ensure the mold design and grade can withstand maximum uniaxial pressure (30+ MPa) to drive particle rearrangement without structural failure.

- If your primary focus is Optical Purity: Optimize the sintering schedule to achieve density quickly while minimizing the time spent at peak temperatures to limit carbon ion diffusion.

Success in vacuum hot pressing relies on leveraging the mold's strength while strictly controlling the microstructure to block the inevitable carbon migration.

Summary Table:

| Function Category | Key Role | Impact on ZnS Ceramic |

|---|---|---|

| Mechanical | Pressure Transmission | Drives particle rearrangement and 30-35 MPa densification |

| Structural | Geometric Containment | Maintains shape integrity under high-temperature uniaxial pressure |

| Thermal | Heat Conductivity | Ensures uniform heating to prevent internal stresses |

| Chemical | Carbon Source | Can cause carbon diffusion and 8.9 μm infrared absorption defects |

Maximize Your Material Performance with KINTEK

Precise control over vacuum hot pressing requires high-performance equipment that balances mechanical strength with thermal uniformity. KINTEK provides industry-leading solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of ZnS ceramic production and advanced material research.

Our expert R&D and manufacturing teams are ready to help you overcome carbon diffusion challenges and achieve superior optical purity. Contact KINTEK today to optimize your lab's high-temperature processes.

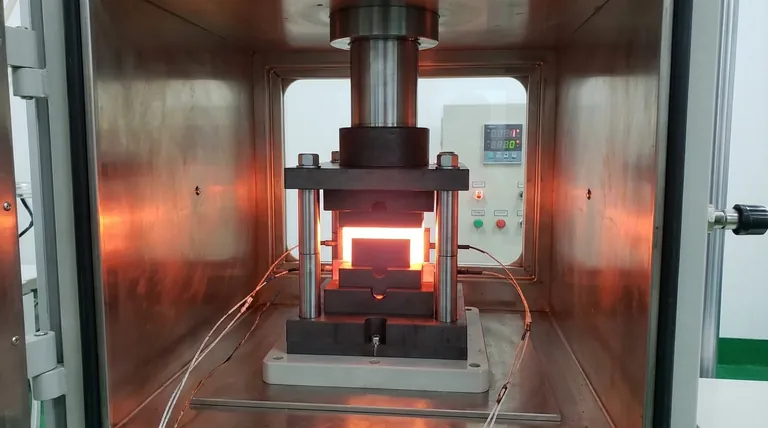

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the primary advantages of industrial SPS vs. vacuum hot-pressing for Ti-6Al-4V? Achieve Superior Microstructure

- What is the purpose of applying vibration to the loaded graphite mold? Enhance TiAl-SiC Composite Sintering Performance

- What are the processing advantages of RHS or SPS for A357 aluminum composites? Achieve Near-Full Density Faster

- What is the primary function of a vacuum hot press furnace in the preparation of Fe-based amorphous alloy/aluminum microlaminated composites? Achieve Perfect Solid-State Bonding

- Why is a vacuum hot press sintering furnace considered superior to atmospheric sintering for preparing high-purity dense magnesium oxide? Achieve Maximum Density and Purity

- What are the advantages of using a vacuum or protected atmosphere in sintering? Boost Material Purity and Performance

- How does the uniaxial pressure applied by a vacuum hot press furnace affect the microstructure of ZrC-SiC materials?

- What role does a vacuum hot press sintering furnace play in Ti/Al2O3 processing? Achieve 99% Density