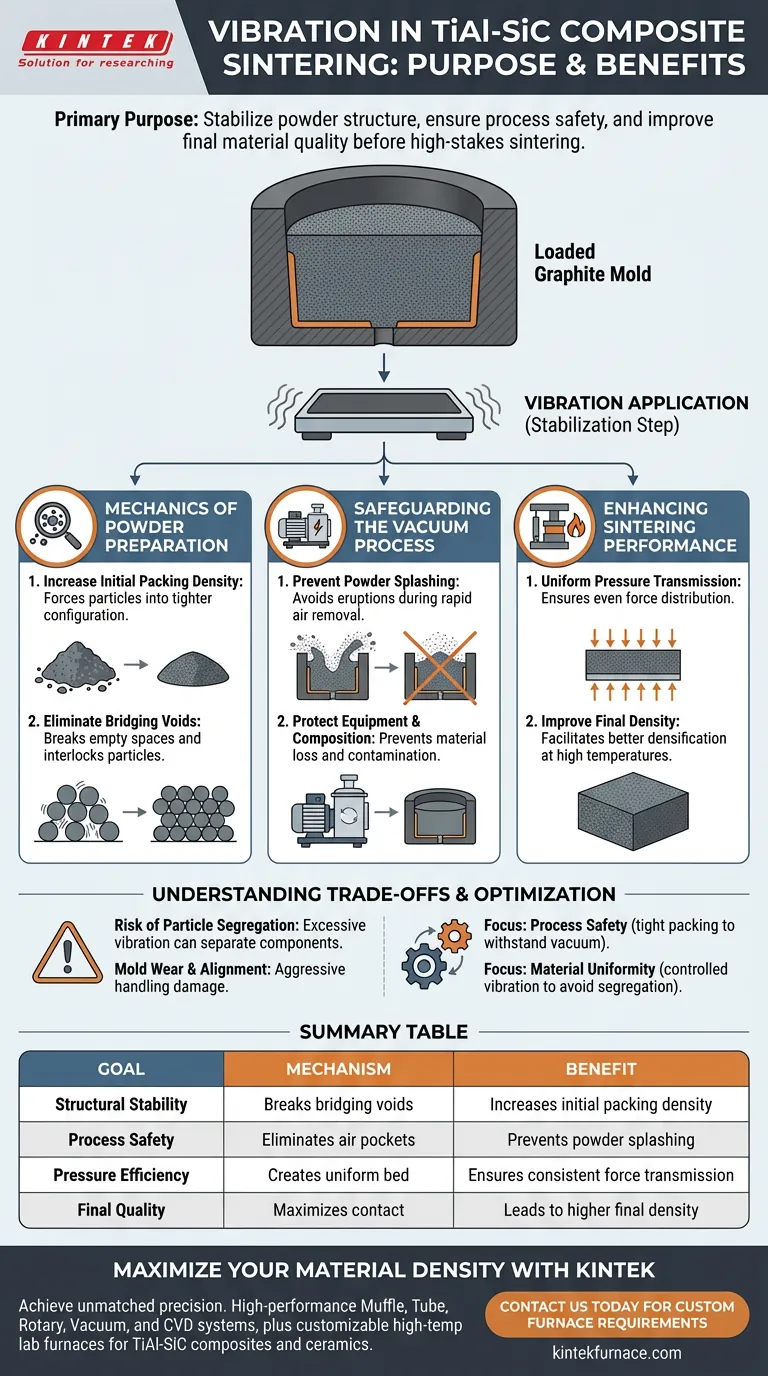

The primary purpose of applying vibration to the loaded graphite mold is to stabilize the powder structure before the high-stakes sintering process begins. This mechanical step increases the initial packing density and breaks down "bridging" voids between particles, which is essential for process safety and final material quality.

Vibration serves as a critical stabilization step that prevents powder loss during vacuum evacuation and ensures that the hydraulic pressure applied later is transmitted uniformly. Without this step, the structural integrity of the final TiAl-SiC composite is compromised by uneven densification.

The Mechanics of Powder Preparation

To understand why vibration is necessary, one must look at how loose powders behave within the constraints of a graphite mold.

Increasing Initial Packing Density

When TiAl and SiC powders are poured into a mold, they naturally settle in a loose, disordered state. Applying vibration forces these particles to settle into a tighter configuration. This increases the mass of material within the fixed volume of the mold before any heat or pressure is applied.

Eliminating Bridging Voids

In a loose powder bed, particles often lean against one another, creating empty spaces or "bridges" that do not collapse under gravity alone. Vibration introduces kinetic energy that breaks these bridges. This ensures that the particles interlock properly, removing large air pockets that could cause defects.

Safeguarding the Vacuum Process

The environment inside a hot-press furnace is harsh. Vibration acts as a safeguard against the physical forces generated during the evacuation stage.

Preventing Powder Splashing

Before heating begins, the furnace chamber is evacuated to create a vacuum. If the powder is loosely packed and contains trapped air pockets, the rapid removal of air can cause the powder to erupt or "splash" out of the mold.

protecting Equipment and Composition

This splashing results in material loss, altering the intended composition of the composite. Furthermore, flying powder can contaminate the vacuum system. A vibrated, densely packed bed resists this disruption, keeping the material contained within the graphite mold.

Enhancing Sintering Performance

The graphite mold acts as a force transmission medium, transferring external hydraulic pressure (often up to 20 MPa) to the powder.

Uniform Pressure Transmission

For the graphite mold to transmit pressure effectively, the resistance offered by the powder must be uniform. A vibrated powder bed ensures that when the punch applies load, the force is distributed evenly across the entire sample surface.

Improving Final Density

The ultimate goal of hot-pressing is densification through diffusion and reaction at temperatures up to 1250 °C. By ensuring high initial density and uniform pressure distribution, vibration directly contributes to a higher final density in the cured TiAl-SiC composite.

Understanding the Trade-offs

While vibration is essential, it must be applied correctly to avoid introducing new problems.

Risk of Particle Segregation

TiAl and SiC particles likely have different densities and sizes. Excessive or incorrect vibration can cause these distinct materials to separate (segregate) rather than mix. This would lead to a non-homogeneous composite with uneven mechanical properties.

Mold Wear and Alignment

The graphite mold serves as both a container and a precision tool for pressure transmission. Aggressive vibration handling can potentially damage the mold walls or misalignment the punch, which would compromise the vacuum seal or the direction of pressure application.

Optimizing Your Sintering Preparation

The application of vibration is not merely a packing step; it is a quality control measure that dictates the success of the sintering cycle.

- If your primary focus is Process Safety: Ensure the powder is packed tightly enough to withstand vacuum evacuation without splashing or material loss.

- If your primary focus is Material Uniformity: Use controlled vibration to eliminate voids without inducing segregation between the TiAl and SiC components.

By treating the vibration step as a critical variable rather than a formality, you ensure the consistent production of high-density, defect-free composites.

Summary Table:

| Goal | Mechanism | Benefit |

|---|---|---|

| Structural Stability | Breaks bridging voids | Increases initial packing density |

| Process Safety | Eliminates air pockets | Prevents powder splashing during vacuum evacuation |

| Pressure Efficiency | Creates uniform bed | Ensures consistent force transmission from the punch |

| Final Quality | Maximizes contact | Leads to higher final density and material homogeneity |

Maximize Your Material Density with KINTEK

Achieve unmatched precision in your hot-pressing sintering workflows. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, plus customizable high-temp lab furnaces tailored to your unique research needs. Whether you are developing advanced TiAl-SiC composites or specialized ceramics, our equipment provides the uniform thermal and pressure control necessary for defect-free results.

Ready to elevate your lab's efficiency? Contact us today to discuss your custom furnace requirements with our technical team!

Visual Guide

References

- Microstructure and High-Temperature Compressive Properties of a Core-Shell Structure Dual-MAX-Phases-Reinforced TiAl Matrix Composite. DOI: 10.3390/cryst15040363

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the significant advantage of using a vacuum hot press furnace compared to pressureless sintering for preparing highly dense h-BN ceramics? Achieve Near-Theoretical Density with Mechanical Force

- What role do hot press furnaces play in powder metallurgy? Achieve High-Density Components Efficiently

- Why is it necessary to treat graphite molds containing mixed powders in a vacuum drying oven before vacuum hot press sintering? Prevent Porosity and Ensure Maximum Density

- What are the processing advantages of SPS systems for LaFeO3 ceramics? Achieve High Density with Precision

- What core role does a vacuum hot press furnace play in the densification process of copper-carbon nanotube composites? Achieve High-Performance Cu-CNT Materials

- How does a vacuum press work? Harness Atmospheric Pressure for Perfect Clamping

- What is the core processing value of a vacuum hot pressing sintering furnace? Master AZ31 Magnesium Alloy Density

- What are the key steps in vacuum hot pressing? Achieve High-Density Materials for Demanding Applications