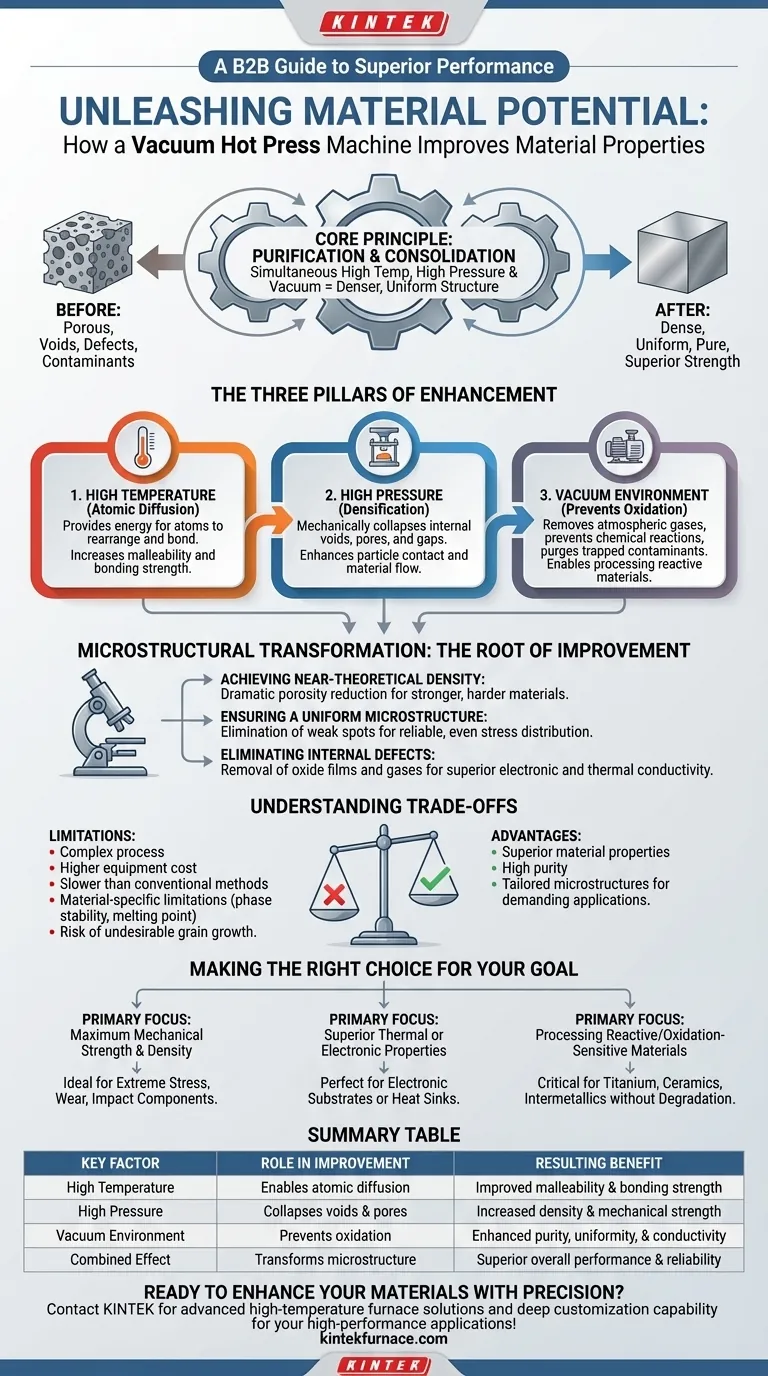

In short, a vacuum hot press machine improves material properties by simultaneously applying high temperature, high pressure, and a vacuum environment. This unique combination forces a material's atoms into a denser, more uniform structure by eliminating internal voids and preventing chemical contamination like oxidation, resulting in superior strength and performance.

The core principle is one of purification and consolidation. By removing atmospheric gases and physically squeezing a material while its atoms are energized by heat, the process systematically eliminates the microstructural defects that inherently weaken a material.

The Three Pillars of Enhancement: Heat, Pressure, and Vacuum

To understand the improvements, you must first understand the distinct role each core element plays in transforming the material at a microscopic level. These three forces work in concert to achieve results that none could accomplish alone.

The Role of High Temperature

High temperature provides the necessary energy for atoms within the material to move. This process, known as atomic diffusion, allows particles to rearrange themselves into a more stable and dense configuration.

Heat essentially makes the material more malleable on a microscopic scale. It increases the bonding strength between individual particles once they are brought into contact.

The Role of High Pressure

High pressure is the physical force that drives densification. It mechanically collapses internal voids, pores, and gaps that are universally present in powdered or less-processed materials.

This pressure enhances particle-to-particle contact, creating a larger surface area for bonding to occur. It facilitates material transport through mechanisms like plastic flow and creep, forcing material to fill in any remaining empty space.

The Critical Function of the Vacuum

The vacuum environment is arguably the most critical element for processing advanced materials. Its primary function is to prevent oxidation and other unwanted chemical reactions by removing atmospheric gases like oxygen and nitrogen.

Furthermore, the vacuum actively pulls residual gases out from within the material's pores. This purges the structure of trapped contaminants that would otherwise create internal weak points and inhibit full densification. For alloys, it also improves the wettability between different liquid and solid phases, promoting a more homogenous final product.

Microstructural Transformation: The Root of Improvement

The combination of heat, pressure, and vacuum directly manipulates a material's internal architecture. The property enhancements you observe are a direct result of these fundamental structural changes.

Achieving Near-Theoretical Density

The most significant outcome is the dramatic reduction or elimination of porosity. By squeezing out voids, the process pushes the material's density closer to its theoretical maximum. A denser material is almost always a stronger, harder, and more durable one.

Ensuring a Uniform Microstructure

The process promotes a highly consistent and homogenous internal structure. This uniformity eliminates weak spots and ensures that stress is distributed evenly throughout the component, drastically improving its overall mechanical reliability and performance.

Eliminating Internal Defects

Beyond just empty pores, the process removes or prevents the formation of other defects. Removing oxide films before bonding and purging dissolved gases results in a cleaner, more structurally sound material with superior electronic and thermal conductivity.

Understanding the Trade-offs

While powerful, vacuum hot pressing is not a universal solution. Acknowledging its limitations is key to using it effectively.

Process Complexity and Cost

Vacuum hot press systems are sophisticated and expensive pieces of equipment. The process itself is often slower and more complex to run than conventional sintering or forging methods, making it best suited for high-value or high-performance applications.

Material Limitations

Not all materials can withstand the extreme conditions. The high temperatures and pressures can damage or alter certain alloys or composite structures. The material's phase stability and melting point are critical considerations.

Risk of Undesirable Grain Growth

While the goal is a uniform microstructure, improper parameters can be detrimental. Holding a material at too high a temperature for too long can cause excessive grain growth, which can, in some cases, reduce the material's strength and fracture toughness.

Making the Right Choice for Your Goal

Selecting this process depends entirely on the performance you require from the final component.

- If your primary focus is maximum mechanical strength and density: This process is an ideal choice for creating components that must withstand extreme stress, wear, or impact.

- If your primary focus is superior thermal or electronic properties: The dense, pure, and uniform structure created by hot pressing minimizes barriers to electron and phonon flow, making it perfect for high-performance electronic substrates or heat sinks.

- If your primary focus is processing reactive or oxidation-sensitive materials: The vacuum environment is the critical enabler, making it possible to consolidate materials like titanium, certain ceramics, and intermetallics without degradation.

By controlling these fundamental forces, you can engineer materials with precisely tailored microstructures designed for the most demanding applications.

Summary Table:

| Key Factor | Role in Improvement | Resulting Benefit |

|---|---|---|

| High Temperature | Enables atomic diffusion for particle rearrangement | Improved malleability and bonding strength |

| High Pressure | Collapses voids and pores for densification | Increased material density and mechanical strength |

| Vacuum Environment | Prevents oxidation and removes contaminants | Enhanced purity, uniformity, and conductivity |

| Combined Effect | Transforms microstructure to eliminate defects | Superior overall performance and reliability |

Ready to enhance your materials with precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum hot press machines can deliver superior strength and purity for your high-performance applications!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?