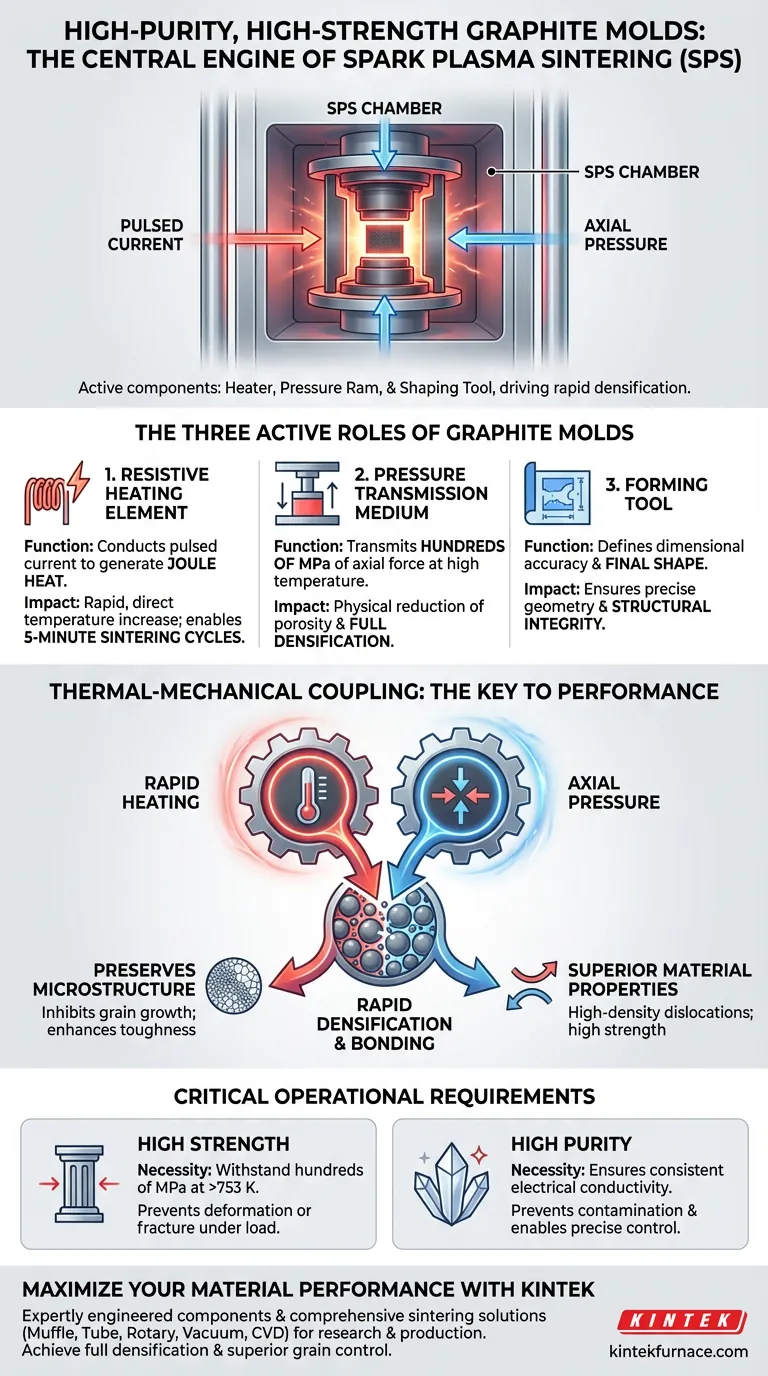

High-purity, high-strength graphite molds act as the central engine of the Spark Plasma Sintering (SPS) process, functioning simultaneously as the heating element, the pressure ram, and the shaping tool. Rather than merely holding the powder, these molds actively convert electrical energy into heat and transmit immense physical force to drive rapid densification.

Core Takeaway The unique value of these graphite molds lies in their ability to facilitate "thermal-mechanical coupling." By acting as both a resistive heater and a high-strength pressure transmitter, they enable full densification of composite materials in minutes while effectively suppressing grain growth.

The Three Active Roles of Graphite Molds

In the SPS process, the mold is an active component of the machine's electrical and mechanical circuit.

1. The Resistive Heating Element

The primary reference highlights that graphite molds possess excellent electrical conductivity. They act directly as resistive heating elements within the system.

When thousands of amperes of pulsed current pass through the mold, it efficiently converts this electrical energy into thermal energy. This generation of Joule heat allows for rapid and direct temperature increases, unlike conventional sintering which relies on external heating elements.

2. The Pressure Transmission Medium

High-strength graphite is essential because it must retain its mechanical integrity at extremely high temperatures.

The molds function as a transmission medium, accurately transferring hundreds of megapascals of axial pressure to the sample. This forces the powder particles together, physically reducing porosity even before full sintering temperatures are reached.

3. The Forming Tool

As noted in the supplementary data, the graphite mold serves as the physical containment vessel.

It defines the dimensional accuracy and final shape of the sample. This ensures that the loose powder is consolidated into a precise geometric form during the sintering cycle.

The Phenomenon of Thermal-Mechanical Coupling

The "deep need" in SPS is achieving full density without degrading the material's microstructure. Graphite molds make this possible through a specific physical basis.

Achieving Rapid Densification

The combination of internal heating and axial pressure creates thermal-mechanical coupling.

This coupling drives materials like TiB2-SiC-Ti3SiC2 to achieve full densification in a very short period. The simultaneous application of heat and force accelerates the bonding between particles far faster than heat alone.

Preserving Microstructure

The speed of this process is critical for material performance.

Because the graphite molds allow for fast heating rates and short sintering times (often within 5 minutes), the process effectively inhibits grain growth. This suppression of grain coarsening preserves fine nano-precipitate phases, which significantly enhances fracture toughness and flexural strength.

Critical Operational Requirements

While graphite is the material of choice, standard grades are insufficient for SPS applications.

The Necessity of High Strength

The process requires the mold to withstand axial pressures of up to hundreds of megapascals while at sintering temperatures (e.g., 753 K or higher).

If the graphite lacks high-temperature mechanical strength, the mold will deform or fracture under the load, compromising the pressure transmission necessary for high-density dislocations.

The Necessity of High Purity

Impurities in the graphite can alter the electrical resistance and contaminate the composite material.

High purity ensures consistent conductivity for stable Joule heating. This consistency is vital for maintaining the precise temperature control required to inhibit grain growth while ensuring full density.

Making the Right Choice for Your Goal

When evaluating the role of graphite molds in your specific SPS application, consider the following outcome-based principles:

- If your primary focus is Speed and Efficiency: Capitalize on the mold's high conductivity to maximize the heating rate, allowing for sintering cycles as short as 5 minutes.

- If your primary focus is Mechanical Performance: rely on the mold's high-temperature strength to apply maximum axial pressure (hundreds of MPa), which enhances fracture toughness and flexural strength.

- If your primary focus is Microstructural Integrity: Utilize the rapid heating capabilities of the mold to suppress grain coarsening, maintaining fine grain structures and high-density dislocations.

Ultimately, the graphite mold is the critical interface that transforms raw electricity and pressure into a fully densified, high-performance composite material.

Summary Table:

| Role | Primary Function | Impact on Composite Material |

|---|---|---|

| Heating Element | Conducts pulsed current to generate Joule heat | Rapid, direct heating; enables 5-minute cycles |

| Pressure Medium | Transmits hundreds of megapascals of axial force | Physical reduction of porosity and full densification |

| Forming Tool | Defines dimensional accuracy and vessel shape | Ensures precise geometry and structural integrity |

| Microstructure Control | Facilitates thermal-mechanical coupling | Inhibits grain growth; enhances fracture toughness |

Maximize Your Material Performance with KINTEK

High-performance Spark Plasma Sintering requires more than just a furnace; it requires the precision of expertly engineered components. Backed by industry-leading R&D and advanced manufacturing, KINTEK provides high-purity, high-strength graphite molds and comprehensive sintering solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to your specific research or production needs.

Ready to achieve full densification and superior grain control? Contact our technical experts today to find the perfect high-temperature solution for your lab.

Visual Guide

References

- I O Poenaru, V Puţan. Research Regarding Advanced Degassing of Steels for Manufacturing Automotive Components. DOI: 10.1088/1742-6596/3153/1/012016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- What is the significance of using a high-temperature hot-press bonding furnace in MgO sensor heads? Expert Guide

- What is the effect of extended holding time during Vacuum Hot Pressing (VHP)? Enhance Al3Ti Phase Purity and Density

- Why is precise temperature control in vacuum hot press equipment critical for regulating the mechanical properties of Fe-based amorphous alloy composites? Master the Metallurgical Balance for Superior Materials

- What is the significance of dimensional accuracy in hot pressing? Achieve Net-Shape Manufacturing for Cost Savings

- Why must the surface layer of titanium alloy samples be removed by grinding? Ensure High Strength After Vacuum Hot Press

- How does a vacuum hot press furnace benefit sintering experiments? Achieve Superior Material Density and Purity

- What is the purpose of applying vibration to the loaded graphite mold? Enhance TiAl-SiC Composite Sintering Performance

- How does vacuum hot pressing compare to vacuum brazing and sintering? Choose the Right Process for Your Materials