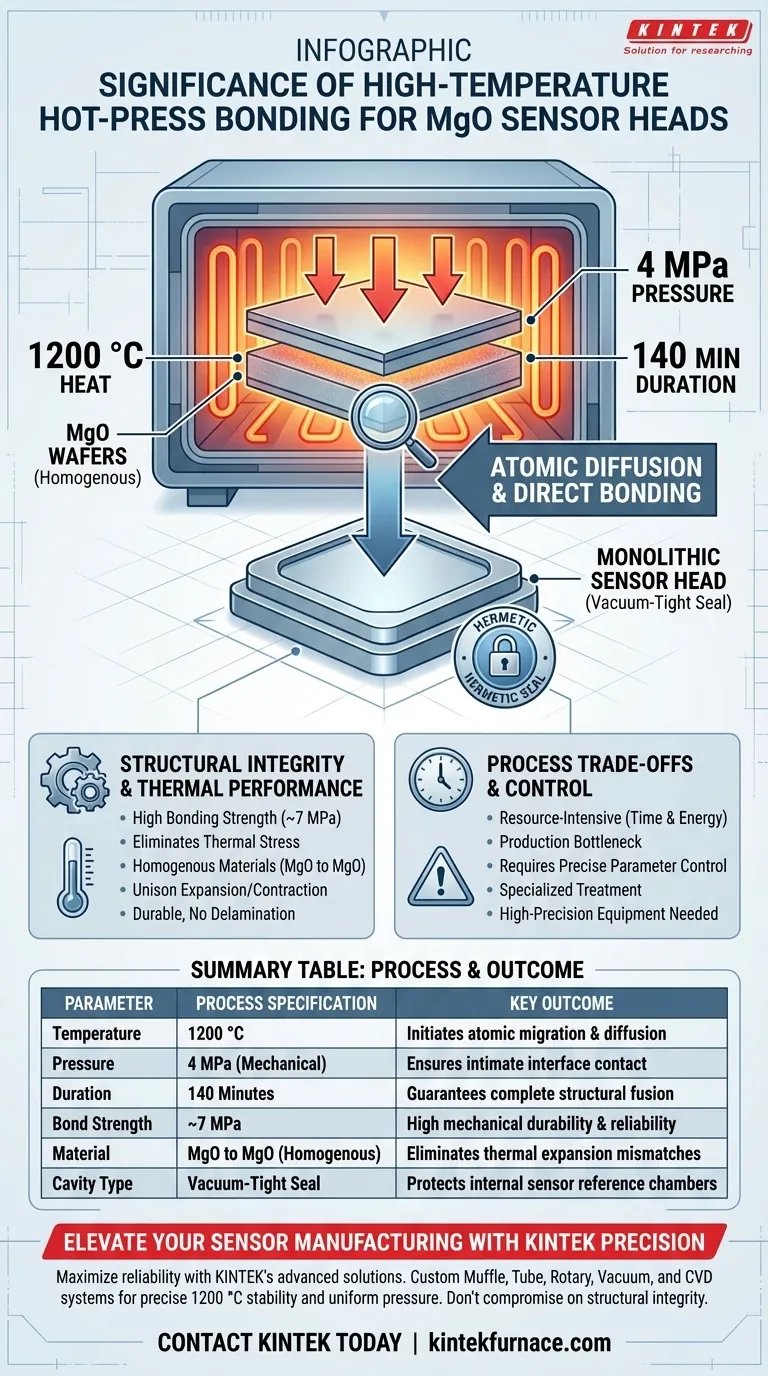

The high-temperature hot-press bonding furnace is the critical enabling tool for creating robust Magnesium Oxide (MgO) sensor heads. By subjecting multilayer wafers to a controlled environment of 1200 °C and 4 MPa of mechanical pressure for 140 minutes, the furnace forces atomic diffusion at the material interfaces. This results in a direct bond that transforms separate layers into a unified, vacuum-tight structure.

The furnace facilitates direct atomic bonding between homogenous materials, achieving a bonding strength of approximately 7 MPa. This process eliminates the need for foreign adhesives and solves thermal stress matching issues, ensuring the sensor remains reliable under extreme operating temperatures.

The Mechanics of Direct Bonding

Achieving Atomic Diffusion

The core function of the furnace is to create the specific conditions necessary for atomic migration.

Simply stacking wafers is insufficient; the furnace must apply a precise coupling of high heat (1200 °C) and significant mechanical pressure (4 MPa).

Under these conditions, atoms at the interface of the MgO wafers diffuse and migrate across the boundary, effectively merging the crystalline structures.

Creating a Vacuum-Tight Seal

This diffusion process does not merely stick the layers together; it fuses them.

The result is the formation of a vacuum-tight cavity within the sensor head.

This hermetic seal is essential for sensor performance, protecting internal reference chambers from external atmospheric interference.

Structural Integrity and Thermal Performance

High Bonding Strength

The direct bonding process yields a mechanical bond of substantial durability.

The resulting interface achieves a bonding strength of approximately 7 MPa.

This magnitude of strength ensures the sensor head allows for handling and operation without delamination or structural failure.

Eliminating Thermal Stress

A critical advantage of this furnace process is the ability to bond homogenous materials (MgO to MgO).

When sensors operate at extreme temperatures, materials with different expansion coefficients typically pull apart or crack due to thermal stress.

Because the furnace bonds identical materials, they expand and contract in unison, resolving thermal stress matching issues and extending the sensor's lifespan.

Understanding the Process Trade-offs

Time and Energy Intensity

While the results are robust, the process is resource-intensive.

The requirement to maintain 1200 °C and 4 MPa for a duration of 140 minutes represents a significant energy cost and production bottleneck.

This is not a rapid-cycle manufacturing step, but rather a specialized treatment for high-value components.

Stringent Control Requirements

The success of atomic diffusion relies on the precise maintenance of environmental parameters.

Fluctuations in pressure below 4 MPa or temperature below 1200 °C could result in incomplete diffusion.

This necessitates high-precision equipment capable of stabilizing extreme conditions over long durations.

Making the Right Choice for Your Sensor Application

The decision to utilize a high-temperature hot-press bonding furnace depends on the specific environmental demands your sensor will face.

- If your primary focus is extreme temperature reliability: This process is essential because it bonds homogenous materials, eliminating failure points caused by thermal expansion mismatches.

- If your primary focus is hermetic sealing: The atomic diffusion process provides the necessary vacuum-tight cavity that mechanical clamping or standard adhesives cannot guarantee.

By leveraging this specialized furnace, you convert separate MgO wafers into a monolithic, stress-resistant component capable of withstanding the harshest conditions.

Summary Table:

| Parameter | Process Specification | Key Outcome |

|---|---|---|

| Temperature | 1200 °C | Initiates atomic migration and diffusion |

| Pressure | 4 MPa (Mechanical) | Ensures intimate interface contact |

| Duration | 140 Minutes | Guarantees complete structural fusion |

| Bond Strength | ~7 MPa | High mechanical durability and reliability |

| Material | MgO to MgO (Homogenous) | Eliminates thermal expansion mismatches |

| Cavity Type | Vacuum-Tight Seal | Protects internal sensor reference chambers |

Elevate Your Sensor Manufacturing with KINTEK Precision

Maximize the reliability of your Magnesium Oxide sensors with KINTEK’s advanced high-temperature hot-press bonding solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your specific lab and industrial high-temperature needs.

Our furnaces provide the precise 1200 °C stability and uniform mechanical pressure required to achieve superior atomic diffusion and vacuum-tight seals. Don't compromise on structural integrity.

Contact KINTEK today to discuss your custom thermal processing needs!

Visual Guide

References

- Jia Liu, Pinggang Jia. Extreme Dual-Parameter Optical Fiber Sensor Composed of MgO Fabry–Perot Composite Cavities for Simultaneous Measurement of Temperature and Pressure. DOI: 10.3390/app15168891

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a Vacuum Hot Press (VHP) furnace facilitate the fabrication of bulk nanostructured Al-4Cu alloys?

- What is the core processing value of a vacuum hot pressing sintering furnace? Master AZ31 Magnesium Alloy Density

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing

- What are the technical advantages of a Spark Plasma Sintering (SPS) system? Achieve Superior TiB2 Ceramic Performance

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- What core role does a vacuum hot press furnace play in Fe-Cu-Ni-Sn-VN? Mastering Nanostructured Composite Production

- What role does a vacuum hot press play in the consolidation of metallic glass powders? Expert Consolidation Insights

- Why is Spark Plasma Sintering (SPS) preferred for Ba0.95La0.05FeO3-δ ceramics? Achieve High Density Fast