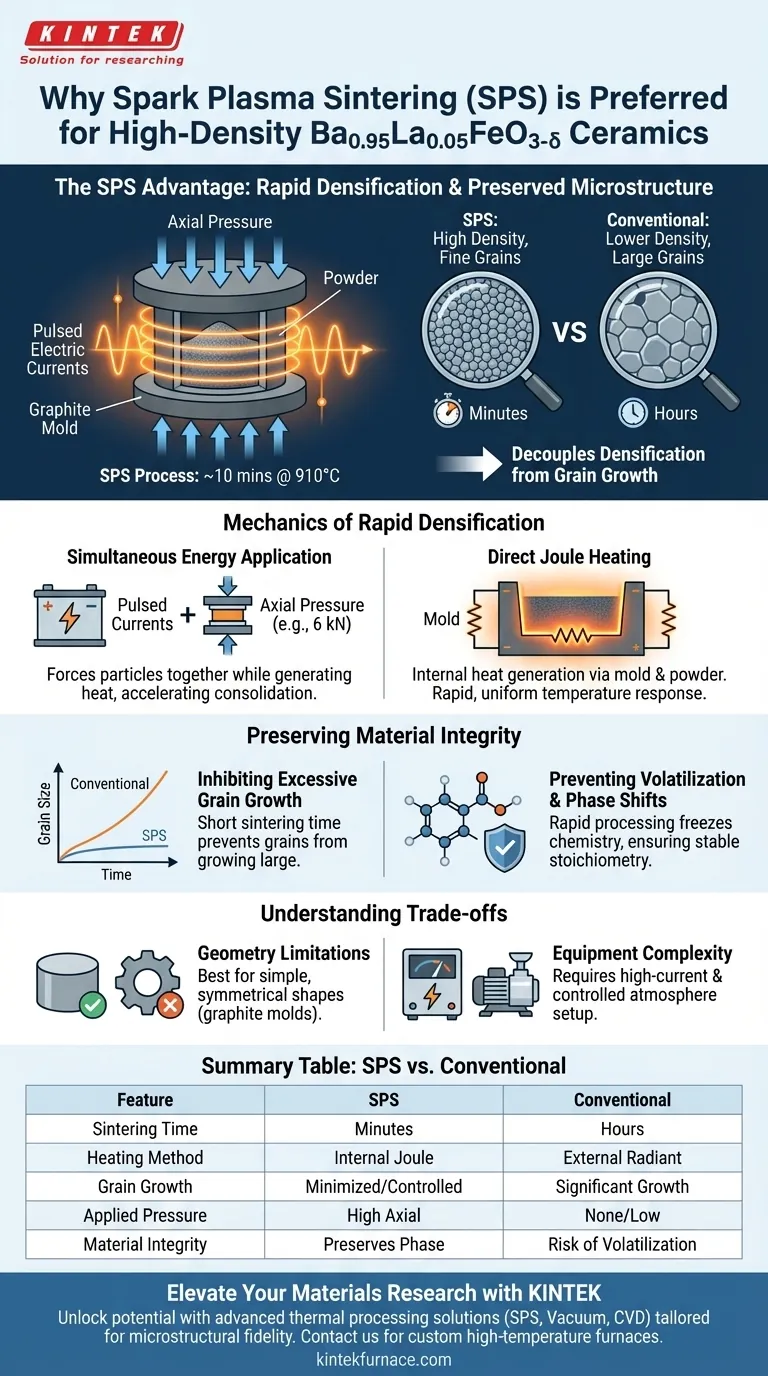

Spark Plasma Sintering (SPS) is the preferred method for producing Ba0.95La0.05FeO3-δ ceramics because it achieves high density while preserving the material's delicate microstructure. By utilizing pulsed electric currents to heat the sample directly while simultaneously applying axial pressure, the system enables rapid densification. This allows the material to reach full density at 910°C in as little as 10 minutes, a timeframe significantly shorter than conventional methods.

The core advantage of SPS lies in its ability to decouple densification from grain growth. By delivering thermal and mechanical energy efficiently, it prevents the component volatilization and phase transformations that plague long-term, high-temperature sintering processes.

The Mechanics of Rapid Densification

Simultaneous Thermal and Mechanical Energy

The SPS process is distinct because it does not rely on passive heating. Instead, it applies pulsed electric currents directly to the mold and the sample.

Simultaneously, the system applies significant axial pressure (often around 6 kN) to the powder compact. This combination forces particles together physically while the current generates heat, accelerating the consolidation process.

Direct Joule Heating

Unlike conventional furnaces that heat from the outside in, SPS utilizes Joule heating. The pulsed current passes through the high-purity graphite mold and the powder itself.

This internal heat generation results in extremely fast heating rates. Because the mold acts as both the container and the resistive heating element, the temperature response is rapid and uniform throughout the sintering cycle.

Preserving Material Integrity

Inhibiting Excessive Grain Growth

One of the most critical challenges in ceramic processing is preventing grains from growing too large, which degrades mechanical properties.

SPS addresses this through speed. Because the sintering time is reduced to minutes rather than hours, there is insufficient time for excessive grain growth to occur. This results in a fine-grain structure that retains superior material properties.

Preventing Volatilization and Phase Shifts

Complex oxides like Ba0.95La0.05FeO3-δ are sensitive to prolonged exposure to high heat. Conventional sintering can lead to the evaporation of volatile components or unwanted phase transformations.

The rapid processing window of SPS effectively freezes the material's chemistry in its desired state. This ensures that the stoichiometry remains stable and the final ceramic matches the theoretical design.

Understanding the Trade-offs

Geometry and Scale Limitations

While SPS is excellent for material quality, it is generally limited by the graphite molds. Producing complex, non-symmetrical shapes or very large components is often more difficult compared to pressureless sintering methods.

Equipment Complexity

SPS systems require high-current power supplies and vacuum or controlled atmosphere environments. This makes the operational setup more complex and capital-intensive than standard muffle furnaces.

Making the Right Choice for Your Goal

To determine if SPS is the right tool for your specific application of Ba0.95La0.05FeO3-δ, consider your performance priorities:

- If your primary focus is microstructural fidelity: Rely on SPS to achieve high density while strictly suppressing grain growth and maintaining phase purity.

- If your primary focus is processing efficiency: Use SPS to dramatically reduce cycle times, achieving results in minutes (e.g., 10 minutes at 910°C) rather than hours.

By leveraging the coupling of electrical and mechanical forces, SPS offers a unique pathway to producing high-performance ceramics that conventional heating cannot match.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Sintering Time | Minutes (e.g., 10 mins) | Hours |

| Heating Method | Internal Joule Heating | External Radiant Heating |

| Grain Growth | Minimized/Controlled | Significant Growth |

| Applied Pressure | High Axial Pressure | None to Low |

| Material Integrity | Preserves Phase & Stoichiometry | Risk of Volatilization |

Elevate Your Materials Research with KINTEK

Unlock the full potential of your high-performance ceramics with KINTEK’s advanced thermal processing solutions. Backed by expert R&D and precision manufacturing, we provide high-quality SPS, Vacuum, and CVD systems tailored for researchers and manufacturers who demand microstructural fidelity and phase purity.

Whether you are producing complex oxides or specialized lab-scale components, our customizable high-temperature furnaces ensure rapid densification without compromising material integrity. Contact KINTEK today to discuss your unique project needs and discover how our equipment can accelerate your innovation.

Visual Guide

References

- Christian Berger, Rotraut Merkle. Ion transport in dry and hydrated Ba<sub>0.95</sub>La<sub>0.05</sub>(Fe<sub>1−<i>x</i></sub>Y<sub><i>x</i></sub>)O<sub>3−<i>δ</i></sub> and implications for oxygen electrode kinetics of protonic ceramic cells. DOI: 10.1039/d5ta03014e

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the primary function of graphite foil within the FAST system? Optimize Your Sintering and Tooling Protection

- What functions do graphite molds serve in the vacuum hot pressing of copper-carbon nanotube composites?

- What role does a vacuum hot press play in the consolidation of metallic glass powders? Expert Consolidation Insights

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance

- What is the core function of a flat tablet press in CSP? Achieve High-Pressure Densification for CaF2 Ceramics

- What is hot pressing sintering and how does vacuum hot pressing sintering improve the process? Achieve Superior Material Density and Purity

- What are the advantages of benchtop SPS/FAST for titanium R&D? Accelerate Your Microstructural Engineering

- How are vacuum hot pressing sintering furnaces classified based on temperature? Explore Low, Medium, and High-Tier Solutions