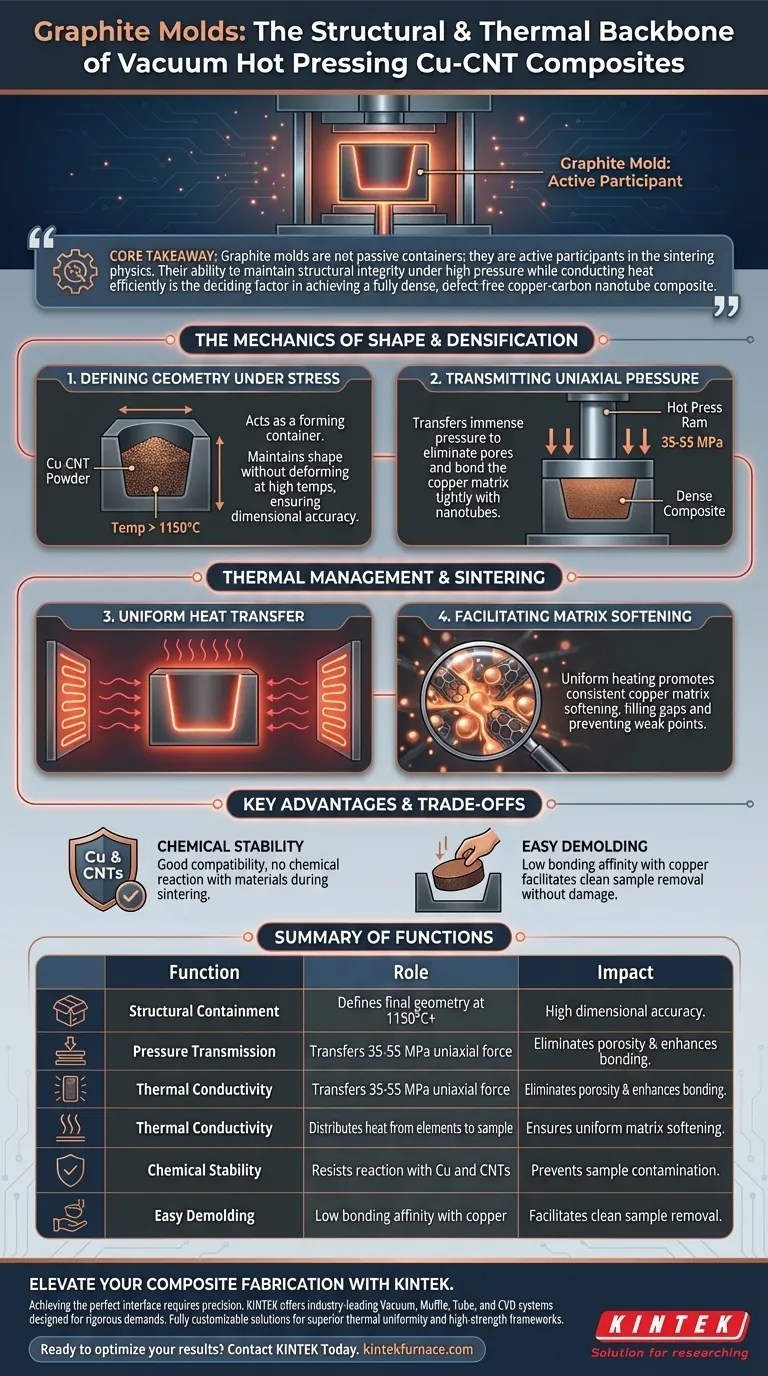

Graphite molds are the structural and thermal backbone of the vacuum hot pressing process. They serve simultaneously as a high-strength container to define the composite's shape, a mechanism for transmitting immense uniaxial pressure, and a conduit for uniform heat distribution, ensuring the copper-carbon nanotube composite achieves the necessary density and bonding.

Core Takeaway Graphite molds are not passive containers; they are active participants in the sintering physics. Their ability to maintain structural integrity under high pressure while conducting heat efficiently is the deciding factor in achieving a fully dense, defect-free copper-carbon nanotube composite.

The Mechanics of Shape and Densification

To understand the role of the mold, you must look beyond its function as a vessel. It acts as the primary tool for translating mechanical force into physical density.

Defining Geometry Under Stress

The most immediate function of the graphite mold is to act as a forming container. It holds the loose composite powder in a specific configuration to define the final dimensions and shape of the material.

Crucially, it must maintain this shape without deforming while subjected to high temperatures (often exceeding 1150°C). If the mold warps, the final component loses its dimensional accuracy.

Transmitting Uniaxial Pressure

The mold serves as a force transmission medium. It transfers the external hydraulic pressure from the hot press ram directly to the powder sample.

This is not a trivial load; the mold must withstand and transmit pressures often ranging from 35 to 55 MPa. This pressure is essential for eliminating pores and forcing the copper matrix to bond tightly with the carbon nanotubes.

Thermal Management and Sintering

The quality of the copper-carbon nanotube interface depends heavily on temperature control. Graphite is selected specifically for its thermal properties in this environment.

Uniform Heat Transfer

Graphite possesses excellent thermal conductivity. This allows the mold to transfer heat quickly and evenly from the heating elements to the powder sample inside.

Facilitating Matrix Softening

Uniform heating ensures that the copper matrix softens consistently throughout the sample volume. This promotes the uniform filling of gaps between the carbon nanotubes and the copper, preventing structural weak points in the final composite.

Understanding the Trade-offs

While graphite is the standard for this process, understanding its interaction with the specific materials involved is vital for process success.

Chemical Stability and Demolding

At high temperatures, many mold materials would react chemically with copper or carbon nanotubes, ruining the sample. Graphite exhibits good chemical compatibility with these materials, remaining stable during the sintering process.

The Demolding Advantage

Because graphite does not easily bond with the copper matrix, it facilitates the demolding process. Once the sintering is complete, the sample can be removed cleanly without damaging the composite surface or the mold itself.

Making the Right Choice for Your Goal

When designing a vacuum hot pressing setup for copper-carbon nanotube composites, prioritize your mold specifications based on your specific quality targets.

- If your primary focus is Maximum Density: Ensure the graphite grade chosen has high compressive strength to withstand pressures exceeding 50 MPa without fracture.

- If your primary focus is Microstructural Homogeneity: Prioritize graphite with high thermal conductivity to ensure the copper matrix softens uniformly across the entire sample geometry.

Graphite molds bridge the gap between loose powder and a solid, high-performance composite by balancing thermal flow with extreme mechanical stability.

Summary Table:

| Function | Role in Process | Impact on Composite |

|---|---|---|

| Structural Containment | Defines final geometry at 1150°C+ | High dimensional accuracy |

| Pressure Transmission | Transfers 35-55 MPa uniaxial force | Eliminates porosity & enhances bonding |

| Thermal Conductivity | Distributes heat from elements to sample | Ensures uniform matrix softening |

| Chemical Stability | Resists reaction with Cu and CNTs | Prevents sample contamination |

| Easy Demolding | Low bonding affinity with copper | Facilitates clean sample removal |

Elevate Your Composite Fabrication with KINTEK

Achieving the perfect copper-carbon nanotube interface requires precision-engineered thermal environments. KINTEK provides industry-leading high-temperature solutions, including Vacuum, Muffle, Tube, and CVD systems, specifically designed to handle the rigorous pressure and temperature demands of advanced material sintering.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique research or production needs. Whether you require superior thermal uniformity for microstructural homogeneity or high-strength frameworks for maximum densification, our team is ready to assist.

Ready to optimize your vacuum hot pressing results?

Contact KINTEK Today for a Professional Consultation

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What is the core function of a vacuum hot press sintering furnace in the consolidation of Cu/rGO composites? Achieve Near-Theoretical Density and Superior Performance

- Why is an industrial hot press critical for lunar ceramic components? Achieve Maximum Density and Impact Resistance

- In which industries is hot pressing commonly used? Essential for Aerospace, Ceramics, and Electronics

- What are the primary functions of a Vacuum Hot Press Furnace (VHP)? Master In-Situ Al3Ti/Al Composite Synthesis

- What environment does a vacuum hot pressing furnace provide for coatings? Achieve Superior Bond Strength & Density

- How does a vacuum hot press work? Unlock Superior Material Density and Purity

- What is the core function of a vacuum hot press furnace? Achieve Near-Perfect Densification for Nano-Copper