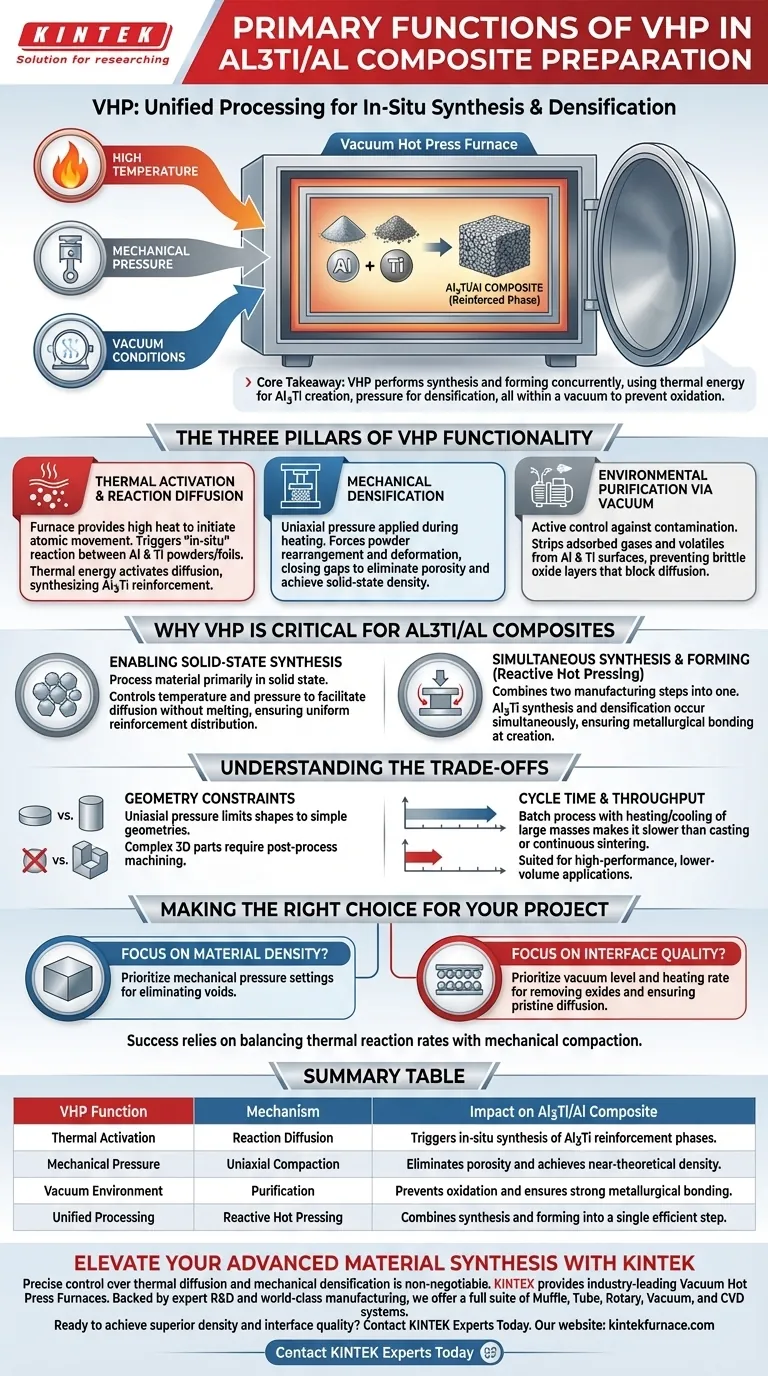

A Vacuum Hot Press Furnace (VHP) serves as a unified processing environment that simultaneously applies high temperatures, mechanical pressure, and vacuum conditions to raw materials. In the specific context of preparing in-situ Al3Ti/Al composites, its primary function is to trigger the chemical reaction between Aluminum and Titanium to create reinforcement phases while mechanically compressing the material to achieve near-perfect density.

Core Takeaway The VHP differs from standard furnaces by performing synthesis and forming concurrently. It utilizes thermal energy to create the Al3Ti reinforcement through diffusion, while mechanical pressure physically forces the material into a solid, non-porous state, all within a vacuum to prevent the rapid oxidation inherent to Aluminum and Titanium.

The Three Pillars of VHP Functionality

To understand how VHP synthesizes these composites, one must look at the three distinct physical mechanisms the furnace controls simultaneously.

Thermal Activation and Reaction Diffusion

The furnace provides the high-temperature environment necessary to initiate atomic movement.

Heat acts as the trigger for the "in-situ" reaction. By reaching specific elevated temperatures, the furnace activates the diffusion of atoms between the Aluminum and Titanium powders (or foils). This thermal energy causes the metals to react chemically, directly synthesizing the Al3Ti intermetallic reinforcement phase within the matrix.

Mechanical Densification

While heat drives the chemistry, uniaxial pressure drives the structure.

The VHP applies significant mechanical force (pressure) to the material during the heating process. This pressure forces the powder particles to rearrange and deform, physically closing the gaps between them. This is critical for achieving a solid-state material with high structural integrity and eliminating the porosity that typically occurs during sintering.

Environmental Purification via Vacuum

The vacuum system is not passive; it is an active control measure against contamination.

Aluminum and Titanium are highly reactive metals that oxidize rapidly at high temperatures. The VHP maintains a vacuum environment to strip away adsorbed gases and volatiles from the powder surfaces. This prevents the formation of brittle oxide layers that would otherwise block the diffusion reaction and weaken the final composite.

Why VHP is Critical for Al3Ti/Al Composites

Beyond the basic mechanics, the VHP solves specific metallurgical challenges associated with this material pairing.

Enabling Solid-State Synthesis

The VHP allows for processing the material primarily in a solid state.

By carefully controlling temperature and pressure, the equipment facilitates reaction diffusion without necessarily melting the entire matrix. This control prevents the segregation of elements often seen in liquid-phase processing, leading to a more uniform distribution of the reinforcement phase.

Simultaneous Synthesis and Forming

The furnace combines two manufacturing steps into one.

In traditional processing, you might synthesize a material and then form it. The VHP achieves "Reactive Hot Pressing," where the synthesis of the Al3Ti reinforcement and the densification of the final part happen at the same time. This ensures that the reinforcement is bonded metallurgically to the matrix at the moment of its creation.

Understanding the Trade-offs

While VHP is essential for high-quality Al3Ti/Al composites, it introduces specific limitations that must be managed.

Geometry Constraints

The pressure applied in a VHP is typically uniaxial (from top and bottom).

This limits the shapes you can produce to simple geometries, such as flat plates, disks, or cylinders. Complex 3D shapes with overhangs or undercuts cannot be manufactured directly in a VHP and requires post-process machining.

Cycle Time and Throughput

VHP is a batch process that requires heating up and cooling down large thermal masses under vacuum.

This makes the process significantly slower than casting or continuous sintering methods. It is a high-precision, lower-volume technique best suited for high-performance applications where material quality outweighs production speed.

Making the Right Choice for Your Project

The VHP is a precision instrument, and its parameters must be tuned to your specific material goals.

- If your primary focus is Material Density: Prioritize the mechanical pressure settings. High pressure is the primary driver for eliminating internal voids and achieving a fully dense, non-porous composite.

- If your primary focus is Interface Quality: Prioritize the vacuum level and heating rate. A deeper vacuum ensures the removal of oxides, allowing for pristine atomic diffusion and stronger bonding between the Al and Ti layers.

Success with VHP relies on balancing thermal reaction rates with mechanical compaction to synthesize a composite that is both chemically reacted and structurally sound.

Summary Table:

| VHP Function | Mechanism | Impact on Al3Ti/Al Composite |

|---|---|---|

| Thermal Activation | Reaction Diffusion | Triggers in-situ synthesis of Al3Ti reinforcement phases. |

| Mechanical Pressure | Uniaxial Compaction | Eliminates porosity and achieves near-theoretical density. |

| Vacuum Environment | Purification | Prevents oxidation and ensures strong metallurgical bonding. |

| Unified Processing | Reactive Hot Pressing | Combines synthesis and forming into a single efficient step. |

Elevate Your Advanced Material Synthesis with KINTEK

Precise control over thermal diffusion and mechanical densification is non-negotiable for high-performance in-situ composites. KINTEK provides industry-leading Vacuum Hot Press Furnaces designed to deliver the rigorous environments required for Al3Ti/Al synthesis and beyond.

Backed by expert R&D and world-class manufacturing, we offer a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or production needs.

Ready to achieve superior density and interface quality? Contact KINTEK Experts Today to find the perfect high-temperature solution for your research.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What Role Does a Graphite Mold Play in Vacuum Hot Pressing? Enhancing Composite Sintering Efficiency

- What are the key benefits of using Vacuum Hot Press equipment in manufacturing? Achieve Superior Material Quality and Performance

- What role do vacuum hot press furnaces play in advanced materials development? Forge High-Density, Pure Materials

- How does a vacuum hot press sintering furnace mitigate copper sintering swelling? Solve Fe-Cu Expansion Issues

- How do graphite molds function during the SPS of Ti-6Al-4Zr-4Nb alloys? Mastering Dual-Action Sintering

- What are the available pressing force and temperature ranges for vacuum hot pressing? Optimize Your Material Processing

- What are the advantages of Spark Plasma Sintering (SPS) systems? Superior High-Entropy Carbide Ceramic Fabrication

- Why is a Vacuum Hot Press Sintering (VHPS) furnace preferred for AlxCoCrFeNi high-entropy alloys? Achieve 99% Density