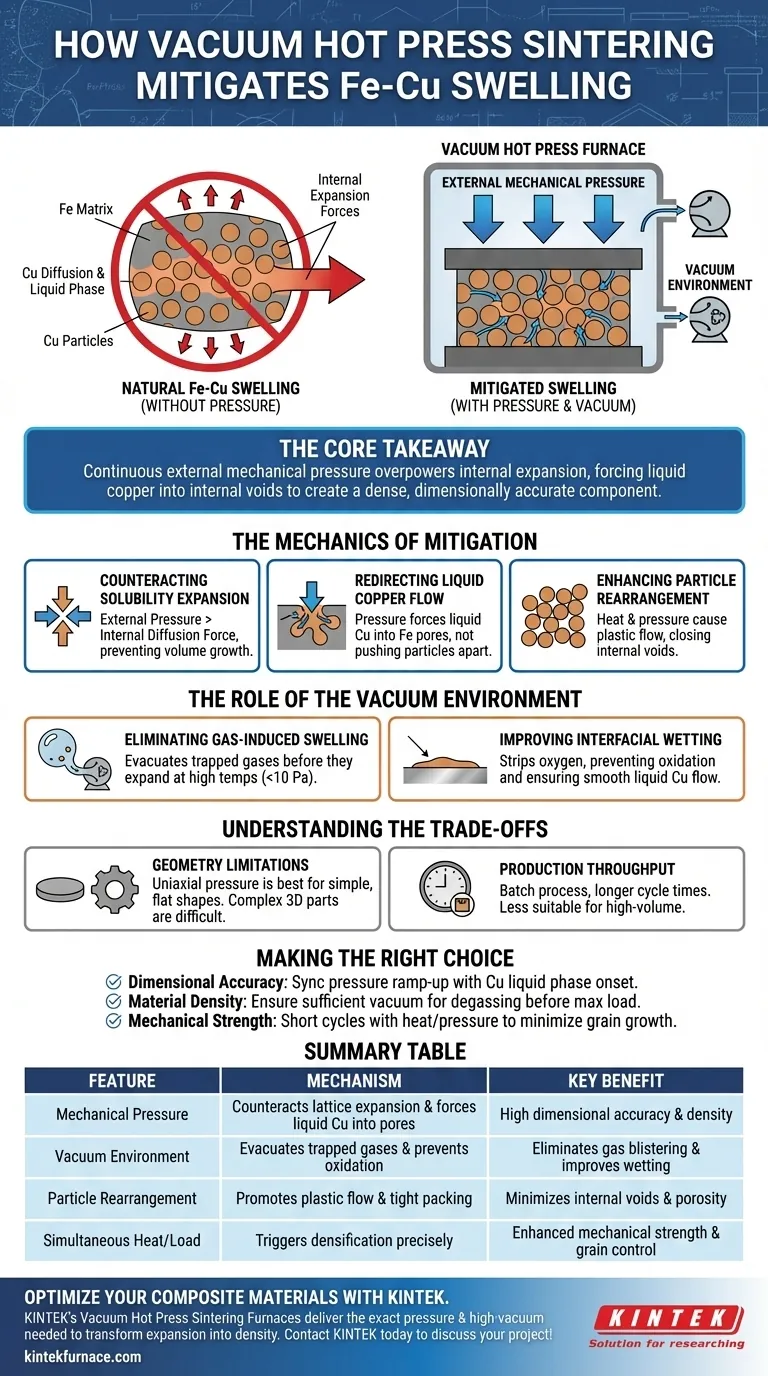

Vacuum hot press sintering mitigates swelling primarily by applying continuous external mechanical pressure during the sintering cycle to counteract internal expansion forces. Instead of allowing the material to expand due to lattice diffusion and solubility changes, the furnace forces the liquid copper phase to infiltrate the pores of the iron-based skeleton.

The Core Takeaway Fe-Cu composites naturally swell during sintering because copper diffuses into iron, expanding the lattice. A vacuum hot press furnace solves this by applying uniaxial pressure that overpowers this expansion, forcing the liquid copper into internal voids to create a dense, dimensionally accurate component.

The Mechanics of Swelling Mitigation

Counteracting Solubility Expansion

In Fe-Cu composites, swelling occurs because copper dissolves into iron more readily than iron dissolves into copper. This difference in solubility leads to lattice expansion and diffusion-based growth.

The vacuum hot press furnace applies external mechanical pressure that physically constrains the material. This external force is greater than the internal expansion pressure generated by the atomic diffusion, effectively preventing the component from growing in volume.

Redirecting Liquid Copper Flow

During liquid phase sintering, molten copper tends to push iron particles apart, contributing to swelling. The furnace's mechanical pressure alters this dynamic significantly.

Rather than separating the iron particles, the pressure forces the liquid copper to flow into the pores of the iron skeleton. This creates a filling effect that increases density without increasing the external dimensions of the part.

Enhancing Particle Rearrangement

The simultaneous application of heat and pressure promotes plastic flow within the matrix. The mechanical force causes solid particles to rearrange and pack more tightly.

This rearrangement closes internal voids that would otherwise remain open or expand. The result is a compact structure where the copper acts as a binder rather than a wedge.

The Role of the Vacuum Environment

Eliminating Gas-Induced Swelling

While mechanical pressure handles the physical expansion, the vacuum environment addresses gaseous expansion. Powder metallurgy compacts often contain adsorbed gases and air trapped in pores.

At high sintering temperatures (e.g., 950°C), trapped gases expand violently, leading to blistering or swelling. The low-pressure vacuum environment (often below 10 Pa) evacuates these gases before pore closure occurs, removing a secondary cause of swelling.

Improving Interfacial Wetting

Oxidation on metal surfaces prevents liquid copper from wetting the iron particles properly. Poor wetting leads to gaps and inefficient densification, which can exacerbate dimensional instability.

The vacuum environment strips oxygen from the sintering chamber, preventing the oxidation of the iron and copper powders. This ensures clean metallic interfaces, allowing the liquid copper to flow smoothly into voids under the applied pressure.

Understanding the Trade-offs

Geometry Limitations

The mechanical pressure in these furnaces is typically uniaxial (applied from top and bottom). This mechanism is highly effective for flat, simple shapes like discs or plates.

However, this limits the production of complex 3D geometries. Parts with undercuts or complex lateral features cannot be effectively pressurized uniformly, potentially leading to uneven density in intricate areas.

Production Throughput

Vacuum hot pressing is inherently a batch process. It combines sintering and densification into a single step, which yields superior material properties but sacrifices speed.

Compared to continuous belt sintering, the cycle times are longer. This makes the process ideal for high-performance, critical components but potentially cost-prohibitive for high-volume, low-cost consumer parts.

Making the Right Choice for Your Goal

To maximize the benefits of vacuum hot press sintering for your Fe-Cu application, consider your specific performance targets.

- If your primary focus is Dimensional Accuracy: Optimize the ramp-up of mechanical pressure to coincide exactly with the onset of the copper liquid phase to instantly counteract swelling.

- If your primary focus is Material Density: Ensure your vacuum levels are sufficient to fully degas the powder prior to applying maximum mechanical load to prevent trapped gas pockets.

- If your primary focus is Mechanical Strength: Utilize the simultaneous heat and pressure to minimize grain growth, as shorter cycle times at pressure preserve fine grain structures (20-400 nm).

The vacuum hot press furnace turns the natural disadvantage of Fe-Cu swelling into an advantage by redirecting that energy into internal densification.

Summary Table:

| Feature | Swelling Mitigation Mechanism | Key Benefit |

|---|---|---|

| Mechanical Pressure | Counteracts lattice expansion and forces liquid Cu into iron pores | High dimensional accuracy and density |

| Vacuum Environment | Evacuates trapped gases and prevents oxidation | Eliminates gas blistering and improves wetting |

| Particle Rearrangement | Promotes plastic flow and tight packing of solid particles | Minimizes internal voids and porosity |

| Simultaneous Heat/Load | Triggers densification precisely at the copper liquid phase | Enhanced mechanical strength and grain control |

Optimize Your Composite Materials with KINTEK

Don't let sintering swelling compromise the precision of your Fe-Cu components. KINTEK’s advanced Vacuum Hot Press Sintering Furnaces are engineered to deliver the exact mechanical pressure and high-vacuum environment required to transform expansion into density.

Backed by expert R&D and world-class manufacturing, KINTEK offers a full range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or production needs. Whether you are aiming for superior dimensional stability or maximum material strength, our technical team is ready to help you design the perfect thermal solution.

Ready to achieve superior densification? Contact KINTEK today to discuss your project!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does vacuum hot pressing compare to vacuum brazing and sintering? Choose the Right Process for Your Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What role does a hot press sintering furnace play in Cf-UHTC production? Achieve Peak Density in Refractory Composites

- What role does a sealed quartz glass tube play in hot press sintering? Achieve Oxide-Free Aluminum Composites

- What are the advantages of Spark Plasma Sintering (SPS)? Enhance Cu2Se Densification and Thermoelectric Performance

- How are vacuum hot pressing sintering furnaces classified based on temperature? Explore Low, Medium, and High-Tier Solutions

- What core role does a vacuum hot press furnace play in Fe-Cu-Ni-Sn-VN? Mastering Nanostructured Composite Production

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?