Spark Plasma Sintering (SPS) systems offer a distinct advantage over traditional hot pressing through the integration of pulsed current direct heating and precision pressure control. By utilizing plasma activation and Joule heating effects, SPS achieves densification rates that are unattainable with conventional external heating methods, specifically allowing for the formation of stable high-entropy carbide structures.

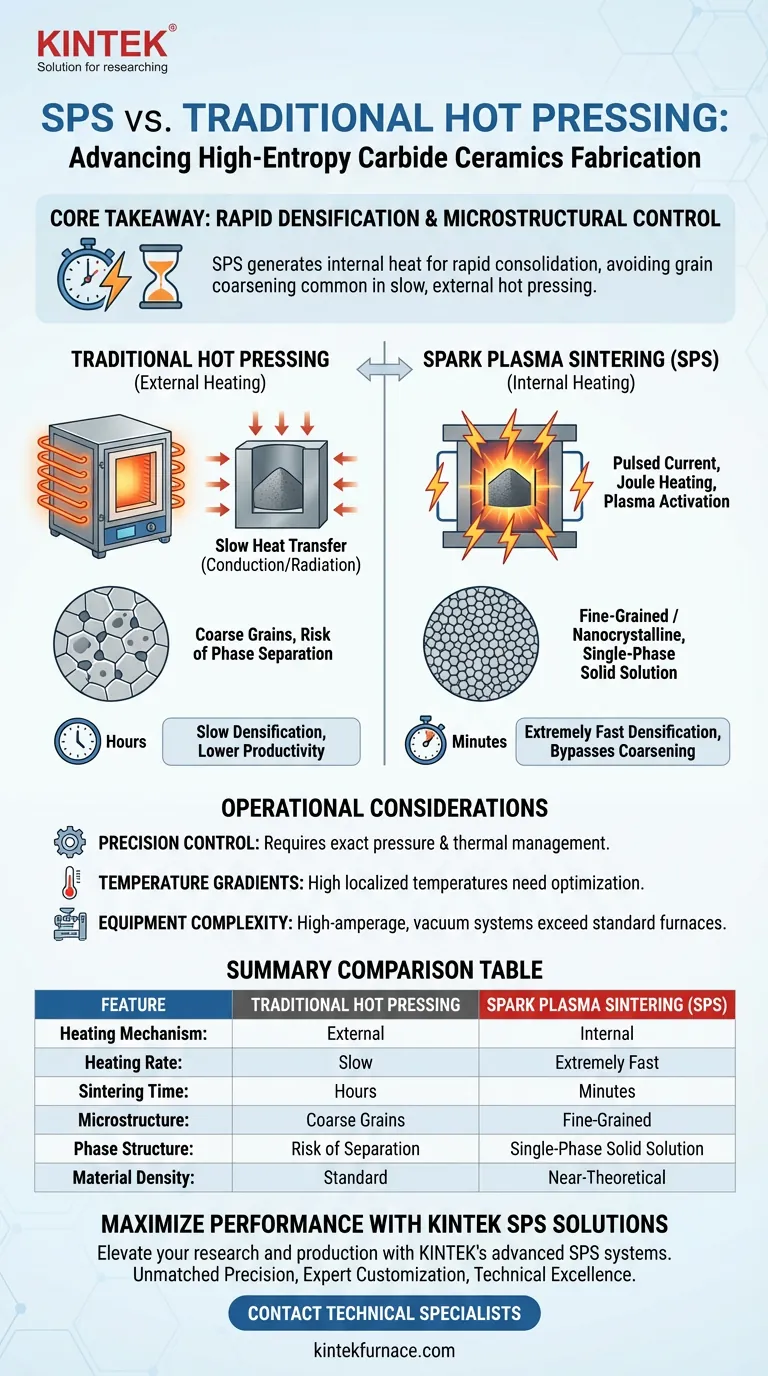

The Core Takeaway Traditional hot pressing relies on slow, external heat transfer which often leads to grain coarsening before density is achieved. SPS solves this by generating heat internally within the powder, enabling the consolidation of five-component high-entropy carbides into a single-phase solid solution with near-theoretical density and preserved fine-grain microstructures.

The Mechanism of Rapid Densification

Internal vs. External Heating

The defining difference lies in how heat is applied. While traditional furnaces heat the sample from the outside in, SPS passes pulsed electric currents directly through the graphite mold and the powder compact.

Joule Heating and Plasma Activation

This process generates Joule heat at the contact points between particles. The primary reference indicates that this internal heating mechanism, combined with plasma activation, significantly accelerates atomic diffusion.

Extreme Heating Rates

Because the heat is generated internally, SPS systems can achieve extremely high heating rates within the critical temperature range of 1800°C to 2300°C. This allows the material to bypass the lower temperature zones where surface diffusion (which causes coarsening) dominates, reaching the sintering temperature almost instantly.

Preserving Microstructural Integrity

Achieving Single-Phase Solid Solutions

For high-entropy ceramics, mixing five distinct carbide components into a single uniform lattice is the ultimate goal. SPS facilitates this by accelerating diffusion so effectively that the components form a completely solid-solution single-phase structure in a very short period.

Inhibiting Grain Growth

Time is the enemy of microstructure. The longer a ceramic sits at high temperature, the larger its grains grow, which reduces mechanical strength.

Short Holding Times

SPS requires very short holding times to achieve densification. This rapid process denies the grains the time needed to coalesce and grow. As a result, the final product retains a fine-grained or even nanocrystalline structure, which directly correlates to superior hardness and fracture toughness.

Operational Constraints and Considerations

The Necessity of Precision Control

While the advantages are clear, the SPS process is highly sensitive. The primary benefit—speed—relies on precision pressure control and exact thermal management.

Temperature Gradients

The mechanism causes the temperature at particle contact points to be significantly higher than the bulk temperature. While this aids diffusion, it requires careful parameter optimization to ensure uniform densification without localized melting or structural inhomogeneities.

Equipment Complexity

Achieving vacuum conditions and managing high-amperage pulsed currents introduces a level of complexity exceeding that of standard resistance furnaces. The process is optimized for high-value performance rather than operational simplicity.

Making the Right Choice for Your Goal

If your primary focus is Maximum Mechanical Performance: Choose SPS to achieve near-theoretical density while maintaining the ultra-fine grain structure required for maximum hardness and toughness.

If your primary focus is Compositional Homogeneity: Choose SPS to force the rapid formation of single-phase solid solutions in complex 5-component high-entropy alloys, avoiding phase separation.

If your primary focus is Process Efficiency: Choose SPS to drastically reduce cycle times from hours to minutes, lowering overall energy consumption per run despite the high peak power usage.

SPS transforms the sintering of high-entropy carbides from a battle against time and temperature into a controlled, rapid consolidation of superior materials.

Summary Table:

| Feature | Traditional Hot Pressing | Spark Plasma Sintering (SPS) |

|---|---|---|

| Heating Mechanism | External (Conduction/Radiation) | Internal (Joule Heating/Plasma) |

| Heating Rate | Slow (Low productivity) | Extremely Fast (Bypasses coarsening) |

| Sintering Time | Hours | Minutes |

| Microstructure | Coarse grains common | Fine-grained / Nanocrystalline |

| Phase Structure | Risk of phase separation | Single-phase solid solution |

| Material Density | Standard density | Near-theoretical density |

Maximize Your Material Performance with KINTEK SPS Solutions

Elevate your research and production with KINTEK’s advanced Spark Plasma Sintering (SPS) systems. Backed by expert R&D and manufacturing, we provide high-precision muffle, tube, vacuum, and customizable high-temp furnace systems designed to meet the rigorous demands of high-entropy ceramic fabrication.

Why partner with KINTEK?

- Unmatched Precision: Achieve near-theoretical density with superior microstructural integrity.

- Expert Customization: Our systems are tailored to your unique lab or industrial requirements.

- Technical Excellence: Benefit from our deep expertise in CVD, rotary, and vacuum furnace technologies.

Ready to transform your sintering process? Contact our technical specialists today to find the perfect customizable solution for your next breakthrough.

Visual Guide

References

- Evaluation of a fluidised catalytic cracking co‐processing method for the production of renewable fuels using Category 3 animal fat and used cooking oils. DOI: 10.2903/j.efsa.2025.9337

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of applying axial pressure during hot press sintering? Achieve High-Density Metal Composites

- What are the unique advantages of Spark Plasma Sintering (SPS)? Unlock Ultrafine Carbide Strength

- What is the function of a rigid mould in vacuum hot pressing? Master Structural Precision in Layered Composites

- Why are hot press furnaces essential in research and development? Unlock Advanced Material Innovations

- What key role does a vacuum hot pressing furnace play in ADSC alloys? Achieve Near-Theoretical Density & Purity

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What role does a Spark Plasma Sintering (SPS) system play in the preparation of Al0.3CoCrFeNiMo0.75 bulk materials?

- Can you use a heat press for laminating? A Practical Guide for DIY and Crafting