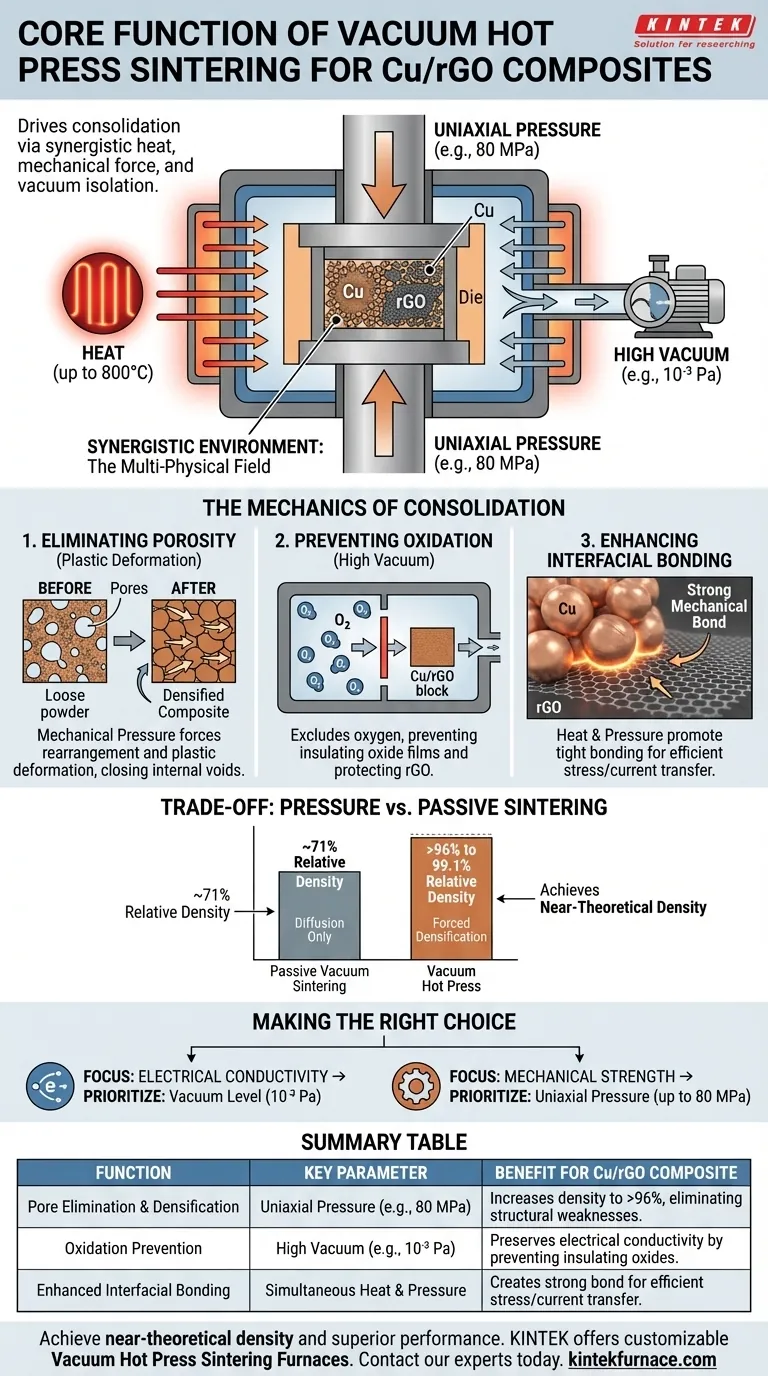

The core function of a vacuum hot press sintering furnace is to drive the consolidation of Copper (Cu) and Reduced Graphene Oxide (rGO) by creating a synergistic environment of heat, mechanical force, and vacuum isolation.

It facilitates the tight bonding of the copper matrix with rGO by applying continuous uniaxial pressure (e.g., 80 MPa) at high temperatures (up to 800°C). This process physically forces the elimination of internal pores while the high vacuum (e.g., 10^-3 Pa) prevents the oxidation that would otherwise compromise the material's electrical and mechanical properties.

Core Takeaway Achieving high performance in Cu/rGO composites requires more than just heat; it requires forced densification in a protected environment. The vacuum hot press acts as a "multi-physical field," utilizing mechanical pressure to crush voids and vacuum to preserve chemical purity, ensuring the composite achieves near-theoretical density and superior electrical conductivity.

The Mechanics of Consolidation

To understand why this equipment is essential, we must look at the specific mechanisms it employs to overcome the natural limitations of copper and graphene.

Eliminating Porosity via Plastic Deformation

Standard sintering relies on atomic diffusion to bond particles, which often leaves voids.

The vacuum hot press introduces mechanical pressure (often between 30 MPa and 80 MPa) directly during the heating phase.

This pressure forces the copper powder particles to undergo rearrangement and plastic deformation. The metal flows into the gaps between particles, effectively closing internal pores that diffusion alone cannot fill.

Preventing Oxidation with High Vacuum

Copper is highly susceptible to oxidation at sintering temperatures, forming copper oxide films that act as electrical insulators.

The furnace maintains a high vacuum environment (typically around 10^-3 Pa).

This effectively excludes oxygen from the system, preventing the copper surface from oxidizing and protecting the rGO from degradation. This is critical for maintaining the high electrical conductivity inherent to both materials.

Enhancing Interfacial Bonding

The ultimate goal is a strong interface between the metal matrix and the reinforcement.

The dual action of heat and pressure promotes a tight mechanical bond between the copper and the rGO sheets.

By removing the physical gaps (voids) and chemical barriers (oxide layers), the furnace ensures that stress and electrical current can transfer efficiently across the Cu/rGO boundary.

Understanding the Trade-offs: Pressure vs. Passive Sintering

It is vital to recognize why this complex equipment is chosen over simpler methods.

The Density Gap

Standard pressureless vacuum sintering relies solely on atomic diffusion. Reference data indicates this method may only achieve relative densities of around 71% in some composite systems.

In contrast, vacuum hot pressing can drive relative density to over 96% or even 99.1%.

The Complexity Cost

The trade-off for this performance is the complexity of the "multi-physical field."

You are managing temperature, pressure, and vacuum simultaneously. Misalignment in any of these parameters—such as applying pressure before the material has reached the correct viscosity (Supercooled Liquid Region)—can lead to defects rather than density.

Making the Right Choice for Your Goal

When configuring a vacuum hot press process for Cu/rGO, your specific operational parameters should align with your end-use requirements.

- If your primary focus is Electrical Conductivity: Prioritize the vacuum level (10^-3 Pa) to strictly prevent the formation of insulating copper oxide films and preserve the rGO structure.

- If your primary focus is Mechanical Strength/Wear Resistance: Prioritize the magnitude of uniaxial pressure (up to 80 MPa) to maximize plastic deformation and eliminate microscopic voids that create structural weaknesses.

Summary: The vacuum hot press is the definitive tool for converting loose Cu/rGO powder into a solid, high-performance billet by mechanically forcing densification while chemically shielding the constituents.

Summary Table:

| Function | Key Parameter | Benefit for Cu/rGO Composite |

|---|---|---|

| Pore Elimination & Densification | Uniaxial Pressure (e.g., 80 MPa) | Increases relative density from ~71% to over 96%, eliminating structural weaknesses. |

| Oxidation Prevention | High Vacuum (e.g., 10⁻³ Pa) | Preserves electrical conductivity by preventing insulating copper oxide formation. |

| Enhanced Interfacial Bonding | Simultaneous Heat & Pressure | Creates a strong mechanical bond between Cu matrix and rGO for efficient stress/current transfer. |

Ready to achieve near-theoretical density and superior performance in your advanced composites?

Backed by expert R&D and manufacturing, KINTEK offers a range of customizable Vacuum Hot Press Sintering Furnaces, designed to meet the precise demands of your Cu/rGO or other advanced material research. Our systems deliver the critical combination of heat, pressure, and vacuum isolation you need for breakthrough results.

Contact our experts today to discuss how we can tailor a solution for your unique needs.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What are the primary application fields for box furnaces and vacuum furnaces? Choose the Right Furnace for Your Process

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations