At its core, a vacuum press is exceptionally versatile because it leverages uniform atmospheric pressure to clamp and form materials. Unlike mechanical presses that create localized pressure points, a vacuum press applies a perfectly distributed force across the entire surface of an object, regardless of its shape, making it ideal for laminating, veneering, and forming a vast range of materials.

The true versatility of a vacuum press stems from its method. By using atmospheric pressure, it perfectly conforms to complex curves and intricate shapes, enabling lamination and forming tasks that are difficult or impossible with traditional mechanical clamping.

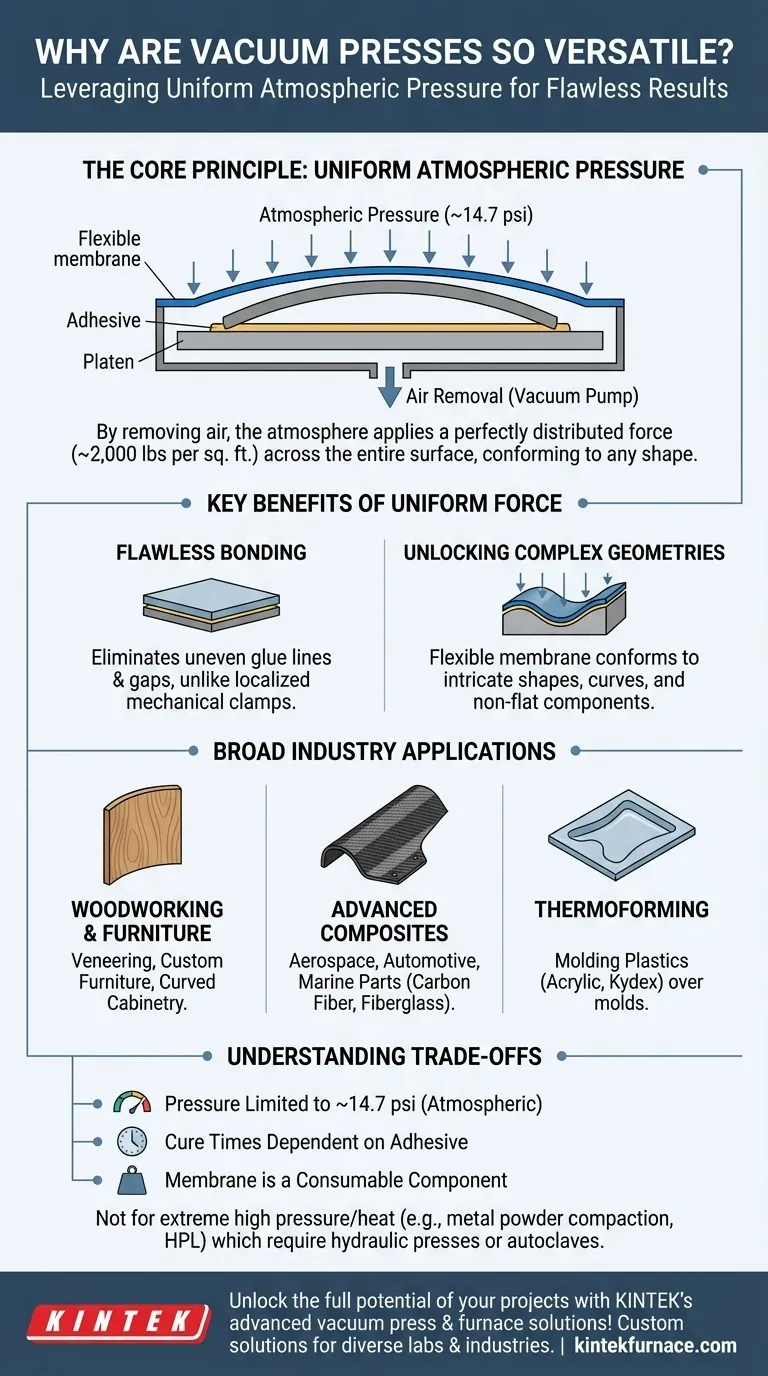

The Principle of Uniform Atmospheric Pressure

To understand its versatility, you must first understand how a vacuum press operates. It isn't a machine that "pulls" or "sucks" materials together; it's a system that removes air so the weight of the atmosphere can do the work.

How It Works

A typical setup involves placing materials and adhesive inside a heavy-duty vinyl or polyurethane bag, or under a flexible membrane on a platen. A pump then removes the air from within the bag or chamber.

As air is evacuated, the external atmospheric pressure—approximately 14.7 pounds per square inch (psi) at sea level—is no longer counteracted by internal pressure. This causes the atmosphere to press down on the flexible membrane with immense, uniform force.

The Power of Even Force

This method provides about 2,000 pounds of clamping force per square foot. Crucially, this force is distributed perfectly evenly across every square inch of the project.

This eliminates the risk of uneven glue lines, gaps, or damage that can occur with mechanical clamps, which concentrate force only at the clamp points.

Unlocking Complex Geometries

Because the pressure is applied by a flexible membrane, it flawlessly follows the contours of any shape. This is the key to its ability to handle curved panels, intricate inlays, and other non-flat components that would be a nightmare to clamp mechanically.

Broad Material and Application Compatibility

This principle of uniform pressure makes the vacuum press a problem-solver across numerous industries and for a wide array of materials.

Woodworking and Furniture Making

In woodworking, vacuum presses are the gold standard for veneering large, flat panels and laminating curved components for custom furniture and cabinetry. The even pressure ensures a flawless bond with no air pockets.

Advanced Composites and Plastics

For industries like aerospace, automotive, and marine, the vacuum press is essential for fabricating composite parts. Layers of materials like carbon fiber, fiberglass, or Kevlar, saturated in resin, are pressed together to create strong, lightweight components.

Thermoforming

Beyond bonding, a vacuum press can be used for thermoforming. A sheet of plastic (like acrylic or Kydex) is heated until pliable and then draped over a mold inside the press. The vacuum pulls the sheet down, forcing it to take the precise shape of the mold.

Understanding the Trade-offs

While highly versatile, a vacuum press is not the solution for every problem. Understanding its limitations is critical for proper application.

Pressure Limitations

The maximum force a vacuum press can achieve is limited to ambient atmospheric pressure (~14.7 psi). For applications requiring extremely high pressure, such as compacting metal powders or high-pressure laminates (HPL), a hydraulic press is necessary.

Cure Times and Temperature

The process speed is often dependent on the cure time of the adhesive being used. While some systems incorporate heating blankets to accelerate curing, they do not typically reach the extreme temperatures and pressures of an autoclave, which is required for certain high-performance aerospace composites.

Bag and Membrane Durability

The flexible bag or membrane is a durable but ultimately consumable component. Sharp corners or improper handling can cause punctures, leading to a loss of vacuum. Careful project preparation is essential to protect the membrane.

Is a Vacuum Press Right for Your Application?

Choosing the right tool requires matching its capabilities to your specific goal.

- If your primary focus is intricate woodworking, veneering, or laminating curved parts: A vacuum press is an unparalleled tool for achieving flawless, professional-grade results.

- If your primary focus is prototyping or fabricating with lightweight composites: A vacuum press provides an accessible and effective method for creating strong, complex composite shapes.

- If your primary focus is high-volume production requiring extreme pressure or heat: You should evaluate more specialized industrial equipment, such as a hydraulic press or an autoclave.

Ultimately, the vacuum press’s power comes from its simple yet effective use of a fundamental physical principle.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Uniform Atmospheric Pressure | Even force distribution for flawless bonding | Veneering, laminating curved parts |

| Flexible Membrane | Conforms to complex shapes and intricate geometries | Composite fabrication, thermoforming |

| Broad Material Compatibility | Works with wood, plastics, carbon fiber, and more | Aerospace, automotive, furniture making |

| Limitations | Max pressure ~14.7 psi; not for extreme heat/pressure | Not ideal for metal powder compaction or HPL |

Unlock the full potential of your projects with KINTEK's advanced vacuum press solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories and industries with high-temperature furnace systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%