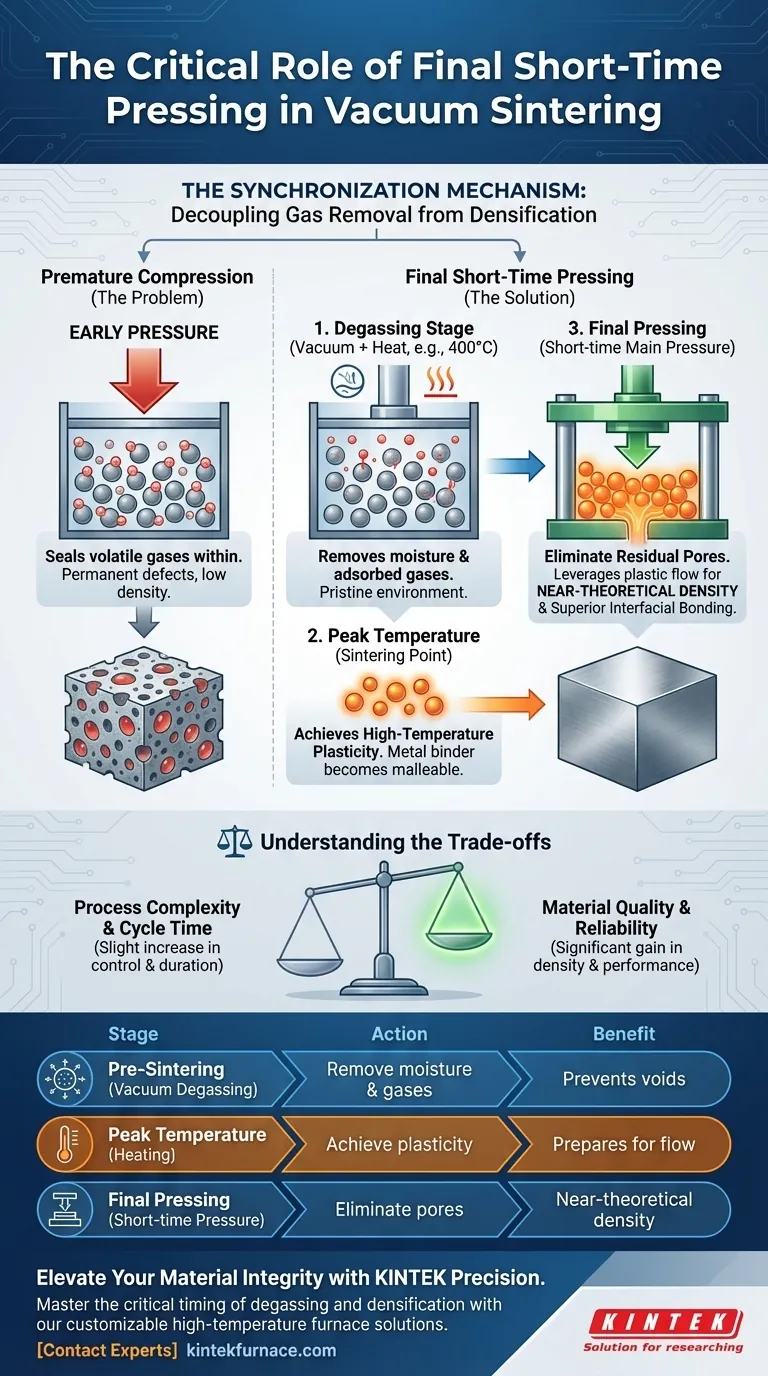

The capability for "final short-time pressing" is the critical synchronization mechanism that decouples the gas removal process from the densification process. By ensuring the main pressure is applied only after the material has been fully degassed and has reached its peak sintering temperature, this feature allows the equipment to utilize the high-temperature plasticity of the metal binder to eliminate residual pores without trapping volatile gases inside the structure.

Core Takeaway: Premature compression seals volatile gases within the material structure, permanently compromising density. By delaying the main pressure until the final sintering stage, you leverage the metal binder's high-temperature plasticity to achieve near-theoretical density while ensuring all contaminants have been successfully evacuated.

The Mechanics of Timing and Density

Avoiding Gas Entrapment

The primary risk in vacuum hot pressing is applying force too early. Powder materials naturally contain adsorbed moisture and gases on their surfaces.

If high pressure is applied before these contaminants are removed, the material pores seal up prematurely. This traps the gas inside the matrix, creating internal defects that are impossible to remove later.

Leveraging Plastic Flow

The "final" aspect of this capability dictates that pressure is applied only when the material reaches its sintering temperature. At this specific thermal point, the metal binder exhibits plastic flow characteristics.

Because the material is softer and more malleable, the applied pressure can effectively force the material to flow into and fill remaining voids. This mechanical action is what drives the component to achieve near-theoretical density.

The Role of the Degassing Stage

Preparing the Microstructure

Before the final press can be effective, the environment inside the furnace must be pristine. This often involves a specific degassing stage (e.g., holding at 400°C) utilizing the vacuum environment.

This stage effectively removes moisture and gases adsorbed on the powder surfaces. If this step is skipped or rushed by early pressing, the high-temperature densification process will inevitably form pores.

Enhancing Interfacial Bonding

The removal of surface contaminants does more than just prevent voids. It ensures the surfaces of the powder particles are clean.

Clean surfaces allow for superior interfacial bonding when the final short-time pressure is applied. This directly impacts the mechanical strength and integrity of the final composite material.

Understanding the Trade-offs

Process Complexity vs. Material Quality

Implementing final short-time pressing requires more sophisticated equipment control than continuous pressing methods. The system must precisely coordinate temperature, vacuum levels, and hydraulic pressure.

If the sensors or control algorithms are inaccurate, the pressure might still be applied too early (trapping gas) or too late (missing the window of maximum plasticity).

Cycle Time Considerations

This method prioritizes quality over speed. By mandating a hold time for degassing and atmosphere reduction before applying pressure, the total cycle time may be slightly longer than a "press-and-go" approach.

However, for high-performance applications, the trade-off is negligible compared to the gain in material density and reliability.

Making the Right Choice for Your Goal

To maximize the effectiveness of your sintering process, consider the following specific adjustments:

- If your primary focus is Maximum Density: Ensure your process recipe delays the main pressure application until the material has fully reached the target sintering temperature to maximize plastic flow.

- If your primary focus is Defect Elimination: Verify that your vacuum degassing stage is sufficient to remove all adsorbents before the "final press" engages, preventing gas pockets.

The value of final short-time pressing lies in its ability to intelligently separate the cleaning phase from the forming phase, ensuring neither compromises the other.

Summary Table:

| Stage | Action | Primary Goal | Benefit |

|---|---|---|---|

| Pre-Sintering | Vacuum Degassing | Remove moisture & adsorbed gases | Prevents internal gas entrapment and voids |

| Peak Temperature | Heating to Sintering Point | Achieve high-temperature plasticity | Prepares metal binder for optimal material flow |

| Final Pressing | Short-time Main Pressure | Eliminate residual pores | Reaches near-theoretical density and strength |

Elevate Your Material Integrity with KINTEK Precision

Don't let premature compression compromise your results. KINTEK provides industry-leading vacuum hot pressing systems designed to master the critical timing of degassing and densification. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique lab requirements.

Ready to achieve near-theoretical density in your components? Contact our technical experts today to discuss how our high-temperature furnace solutions can optimize your sintering process.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the core technology behind vacuum press in metalworking industries? Unlock Precision Metal Forming

- Why is a Vacuum Hot Press (VHP) furnace more suitable for preparing ODS alloys? Superior Uniformity & Density

- What are the unique advantages of Spark Plasma Sintering (SPS) systems for Silicon Carbide? Maximize SiC Performance

- What role does hot pressing play in materials science? Achieve High-Density, Complex Parts Efficiently

- What is the primary function of a hot-pressing furnace in SiC bicrystal synthesis? Achieve Precision Atomic Bonding

- What are the main types of vacuum presses? Discover the Right Press for Your Materials and Applications

- How does the pressurization system of a vacuum hot press affect SiC/TB8 composites? Optimize Matrix Densification

- What are the advantages of SPS for BCZY712 electrolytes? Achieve 98% Density and Superior Proton Conductivity