Precision pressure control serves as the critical mechanical driver in eutectic bonding, working in tandem with thermal energy to create a unified material interface. It applies a uniform force specifically calibrated to fracture surface oxides and drive liquid alloys, such as Gold-Tin (Au-Sn) or Gold-Silicon (Au-Si), into microscopic surface irregularities.

The Core Insight: While heat initiates the phase change of the alloy, it is controlled pressure that ensures physical integration. By forcing the liquid alloy to displace contaminants and trapped air, precision pressure transforms a simple melt into a hermetically sealed, void-free structural bond.

The Mechanics of Pressure in Material Formation

Breaching the Oxide Barrier

Even highly conductive metals often possess a thin, stubborn layer of surface oxidation. Thermal energy alone is frequently insufficient to bypass this barrier.

A precision control system applies specific mechanical force to physically break through these oxide layers. This fracture allows the pristine metal underneath to wet effectively with the eutectic alloy.

Driving Liquid Alloy Flow

Once the eutectic point is reached, the alloy transitions to a liquid state. However, surface tension can cause the liquid to bead rather than spread.

Controlled pressure overcomes this surface tension, promoting the lateral flow of the liquid alloy. This ensures the bonding material distributes evenly across the entire die or wafer interface.

Conquering Surface Topography

At a microscopic level, no wafer surface is perfectly flat; they are comprised of peaks and valleys.

Pressure forces the liquid eutectic alloy to penetrate and fill these microscopic irregularities. This maximizes the contact surface area, which is essential for mechanical strength and electrical conductivity.

Achieving Hermeticity and Reliability

Expelling Interfacial Gases

Air or process gases trapped between the bonding surfaces are the primary cause of voids. Voids weaken the joint and compromise thermal transfer.

By applying a uniform squeeze, the system effectively expels these interfacial gases outward from the center of the bond. This results in a continuous, solid interface necessary for high-reliability applications.

Ensuring Uniformity

Inconsistent pressure leads to tilted dies or uneven bond lines.

A precision system maintains uniform mechanical pressure across the entire surface area. This guarantees that the bond line thickness remains consistent, preventing stress concentration points that could lead to failure.

Understanding the Trade-offs

The Risk of Excessive Force

While pressure is vital, applying too much force can be detrimental. Excessive pressure may cause "squeeze-out," where the conductive alloy flows beyond the bond pad, potentially causing short circuits in fine-pitch applications.

The Consequence of Insufficient Pressure

Conversely, if the pressure is too low, the oxide layer may remain intact. This results in "cold joints" or significant voiding, where the bond lacks hermeticity and mechanical integrity.

Making the Right Choice for Your Goal

To optimize your eutectic bonding process, align your pressure strategy with your specific quality metrics:

- If your primary focus is Hermetic Sealing: Prioritize a pressure profile that maximizes the expulsion of interfacial gases to ensure a void-free seal.

- If your primary focus is Electrical Yield: Focus on limiting pressure to prevent alloy squeeze-out, ensuring the conductive material stays strictly within the designated bond pads.

- If your primary focus is Mechanical Strength: Ensure the pressure is sufficient to fully penetrate microscopic surface irregularities for maximum surface area contact.

True process control lies in balancing sufficient force to displace oxides without compromising the structural dimensions of the device.

Summary Table:

| Mechanism | Role in Material Formation | Impact on Quality |

|---|---|---|

| Oxide Breaching | Breaks surface oxidation layers mechanically | Ensures effective metal wetting |

| Alloy Flow | Overcomes surface tension of liquid alloys | Promotes uniform lateral distribution |

| Topography Filling | Forces alloy into microscopic irregularities | Maximizes contact area and strength |

| Gas Expulsion | Squeezes out trapped air and process gases | Creates void-free, hermetic seals |

| Force Uniformity | Maintains consistent mechanical pressure | Prevents tilted dies and stress points |

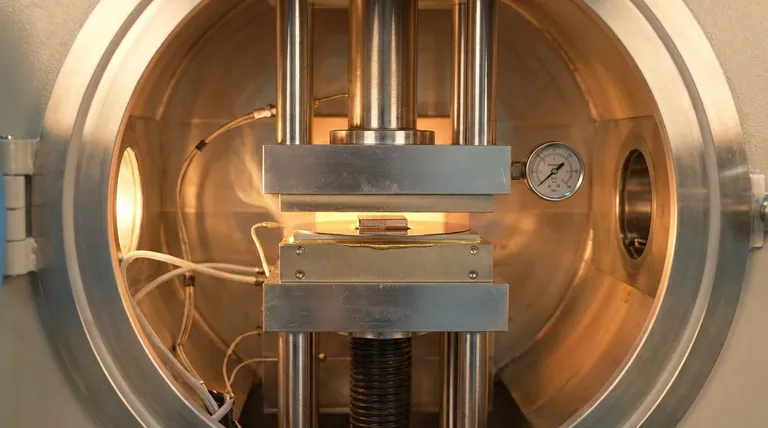

Elevate Your Bonding Precision with KINTEK

Achieving the perfect balance between mechanical force and thermal energy is critical for high-yield eutectic bonding. At KINTEK, we understand that precision is non-negotiable for lab and industrial applications. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique high-temperature processing needs. Whether you are targeting hermetic sealing, electrical yield, or mechanical strength, our lab solutions provide the stability and control required for superior results.

Ready to optimize your material formation? Contact our specialists today to discover how KINTEK's advanced furnace technology can transform your research and production.

References

- Wafer Bonding Technologies for Microelectromechanical Systems and 3D ICs: Advances, Challenges, and Trends. DOI: 10.1002/adem.202500342

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What is the core advantage of using a Hot Pressing Sintering (HPS) furnace? Enhance SiC/YAG Ceramic Density & Strength

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- How does the pressurization system of a vacuum hot press affect SiC/TB8 composites? Optimize Matrix Densification

- What functions does a graphite mold perform? Unlock Superior Densification in Vacuum Hot Pressing

- What are the primary advantages of FAST/SPS in Ti-6Al-4V recycling? Transform Efficiency with Solid-State Sintering

- What is the role of hot press furnaces in composite material production? Unlock Superior Composite Performance

- What role does a vacuum hot press sintering furnace play in Ti/Al2O3 processing? Achieve 99% Density

- What is a hot press machine used for? From custom apparel to aerospace components