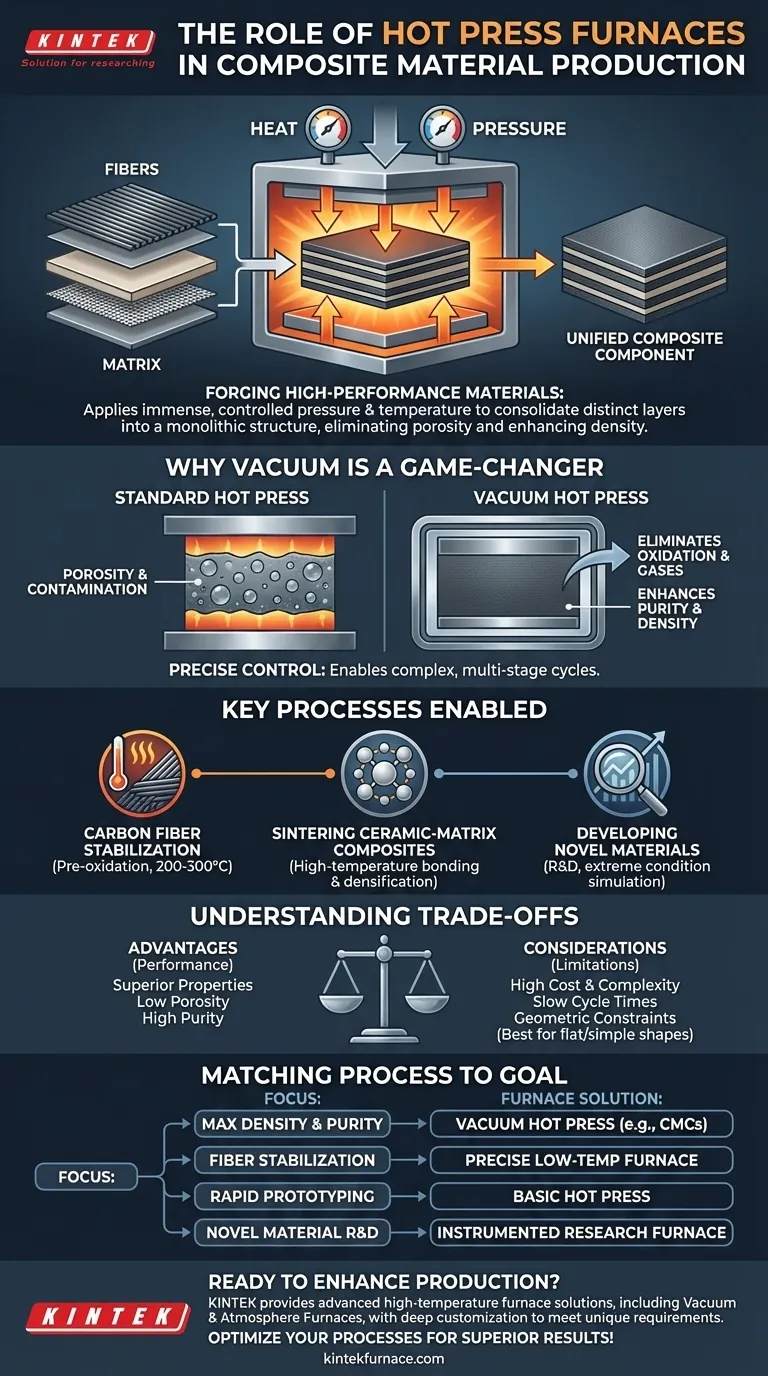

At its core, the role of a hot press furnace is to forge high-performance composite materials by applying immense, controlled pressure and high temperature simultaneously. This process consolidates distinct layers of material—such as fibers and a matrix—into a single, unified component with properties superior to those of its individual parts.

A hot press furnace is not merely a press or an oven; it is a precision instrument that creates a highly controlled environment. Its primary function is to eliminate porosity and ensure intimate contact between material constituents, fundamentally enhancing the final composite's density, strength, and overall performance.

The Fundamental Role: Forging a Unified Material

A composite material's strength is derived from the successful fusion of its components. The hot press furnace is the critical tool that facilitates this transformation from separate layers into a monolithic structure.

Applying Heat and Pressure

The simultaneous application of heat and pressure is the defining characteristic of this process. Heat softens the matrix material, allowing it to flow and wet the reinforcing fibers, while pressure physically compacts the layers together.

This combined action forces out trapped air and volatiles, ensuring a dense, void-free final part. This consolidation is essential for achieving the desired mechanical properties.

Why Vacuum is a Game-Changer for Composites

Standard hot pressing is effective, but vacuum hot press furnaces represent a significant leap in capability. By performing the process in a vacuum, operators gain an unprecedented level of control, enabling the production of next-generation materials.

Eliminating Contamination and Porosity

A vacuum environment removes atmospheric gases like oxygen and nitrogen, which can react with materials at high temperatures and create impurities. This prevents oxidation and ensures the material's chemical purity.

By evacuating the chamber, the furnace also provides a more effective pathway for removing residual gases and moisture from within the composite layup, leading to even lower levels of porosity.

Enabling Precise Temperature and Pressure Control

Advanced vacuum furnaces offer exceptional control over heating and pressure application. This allows for complex, multi-stage cycles tailored to the specific material system.

This precision is crucial for processing sensitive materials and for developing new composites where the processing window is extremely narrow.

Key Processes in Advanced Composite Production

Hot press furnaces are not used for just one task; they are versatile tools employed at various stages of composite development and manufacturing.

Carbon Fiber Stabilization

In the production of carbon-fiber-reinforced composites, the furnace is used for pre-oxidation. This is a low-temperature (200-300°C) heat treatment that stabilizes the raw fiber's structure, preparing it for the much higher temperatures of carbonization.

Sintering Ceramic-Matrix Composites

For materials like Silicon Carbide/Silicon Carbide (SiC/SiC) composites, the furnace is used for high-temperature hot pressing sintering. This process uses heat and pressure to bond ceramic particles together, densifying the matrix around the fibers to create an incredibly tough, heat-resistant component.

Developing Novel Materials

Researchers rely heavily on hot press furnaces to investigate material behavior under extreme conditions. By simulating these environments, they can understand fundamental properties and accelerate the development of new, advanced materials for aerospace, defense, and energy applications.

Understanding the Trade-offs

While powerful, hot press technology is not a universal solution. It involves specific limitations that must be considered.

Cost and Complexity

Hot press furnaces, especially high-vacuum models, are significant capital investments. They require specialized infrastructure and highly trained operators to manage the complex processing cycles.

Cycle Time Limitations

Compared to faster manufacturing methods like injection molding, hot pressing is a relatively slow, batch-based process. The heating, soaking, and cooling cycles can take several hours, limiting production throughput.

Geometric Constraints

The nature of applying uniaxial pressure means hot pressing is best suited for producing relatively simple, flat, or gently curved geometries. Manufacturing parts with highly complex, three-dimensional shapes can be challenging or impossible.

Matching the Process to Your Composite Goal

Choosing the right approach depends entirely on the intended outcome for your material.

- If your primary focus is maximum density and purity (e.g., CMCs): A vacuum hot press is essential for high-temperature sintering and eliminating internal voids.

- If your primary focus is stabilizing precursor fibers: A furnace with precise control in the 200-300°C range is critical for effective pre-oxidation.

- If your primary focus is rapid prototyping of simple laminates: A basic, non-vacuum hot press may provide sufficient consolidation for initial testing.

- If your primary focus is developing novel material systems: A highly instrumented research furnace is required to investigate behavior under precisely controlled conditions.

Ultimately, mastering the hot press furnace is key to unlocking the full performance potential of advanced composite materials.

Summary Table:

| Aspect | Role in Composite Production |

|---|---|

| Primary Function | Consolidates layers into a unified structure by applying heat and pressure simultaneously. |

| Key Benefits | Eliminates porosity, enhances density and strength, ensures material purity. |

| Processes Enabled | Carbon fiber stabilization, sintering of ceramic-matrix composites, novel material development. |

| Considerations | High cost, slow cycle times, geometric constraints for complex shapes. |

Ready to enhance your composite material production with precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored hot press furnaces can optimize your composite processes for superior results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing