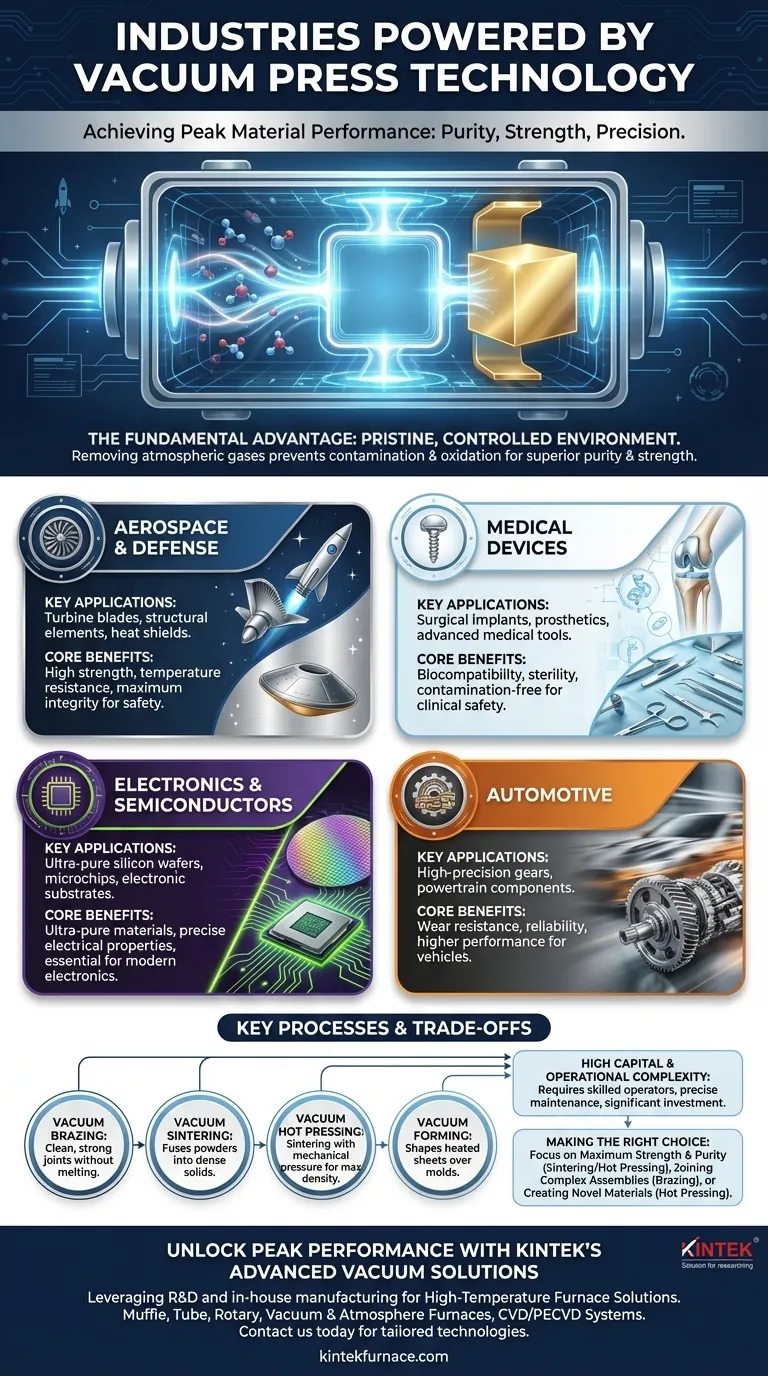

In short, vacuum presses are indispensable in high-stakes industries where material purity, strength, and precision are non-negotiable. Key sectors include aerospace, automotive, electronics, and medical device manufacturing, where they are used to create everything from jet engine turbines and high-performance gears to semiconductor wafers and surgical implants.

The true value of a vacuum press is not just applying pressure; it's the pristine, controlled environment it creates. By removing atmospheric gases, these systems prevent contamination and oxidation, enabling material bonding, shaping, and purification processes that are impossible in open air.

The Fundamental Advantage: Processing in a Void

To understand why these industries rely on vacuum technology, you must first understand the core problem it solves. At the high temperatures required for material processing, the gases in our atmosphere—primarily oxygen and nitrogen—become highly reactive.

Eliminating Contamination and Oxidation

When processing materials like high-performance metal alloys or ceramics, any reaction with atmospheric gases creates impurities. These oxides or nitrides form weak points in the material's structure, compromising its integrity and performance.

A vacuum press removes the air, creating a chemically inert environment. This ensures the final product is exceptionally pure and free from the defects caused by atmospheric reaction.

Enabling High-Integrity Bonding

Processes like vacuum brazing and diffusion bonding rely on this inert environment to create superior joints between components.

Without an oxide layer on the surface, metals can be joined with unparalleled strength and cleanliness. The resulting bond is often seamless and as strong as the parent material itself, a critical requirement for components that cannot fail.

Achieving Full Density and Complex Shapes

Vacuum technology is central to powder metallurgy and advanced ceramics. In processes like vacuum sintering or hot pressing, fine powders are compacted under heat and pressure.

The vacuum removes trapped air between the powder particles, allowing them to fuse into a fully dense, non-porous solid part. This method is essential for creating materials with extreme hardness, wear resistance, and thermal stability.

Key Industrial Applications by Sector

The benefits of vacuum processing directly map to the extreme requirements of modern engineering fields.

Aerospace and Defense

This sector demands materials that are simultaneously lightweight, incredibly strong, and resistant to extreme temperatures.

Vacuum furnaces and presses are used to produce critical components like turbine blades, high-strength structural elements, and heat shields. The process ensures maximum material integrity, which is essential for flight safety and performance.

Medical Devices

Biocompatibility and sterility are the driving requirements in the medical field. Any material implanted in the human body must be free of contaminants that could cause an adverse reaction.

Vacuum processing is used to manufacture surgical implants, prosthetics, and advanced medical tools, ensuring they are pure, strong, and safe for clinical use.

Electronics and Semiconductors

The electrical properties of a semiconductor are highly sensitive to microscopic impurities. Even trace amounts of contaminants can render a microchip useless.

High-vacuum furnaces are essential for producing the ultra-pure silicon wafers and other advanced materials that form the foundation of all modern electronics, from computer chips to electronic substrates.

Automotive

In the push for higher efficiency and performance, the automotive industry increasingly relies on advanced materials.

Vacuum sintering and brazing are used to create high-precision, wear-resistant parts like gears and other powertrain components. This results in longer-lasting, more reliable, and higher-performing vehicles.

Understanding the Associated Processes and Trade-offs

The term "vacuum press" often serves as an umbrella for a family of related high-tech manufacturing processes. Understanding them reveals the technology's versatility and its inherent complexities.

Key Processes: Beyond a Simple 'Press'

- Vacuum Brazing: Joins materials using a filler metal in a vacuum, creating exceptionally clean and strong joints without melting the base components.

- Vacuum Sintering: Uses heat and vacuum to fuse powdered materials (like metals or ceramics) into a solid, dense part.

- Vacuum Hot Pressing: Combines the principles of sintering with direct mechanical pressure to achieve maximum density and superior material properties.

- Vacuum Forming: Shapes a heated sheet of material (metal or plastic) over a mold using suction, ideal for creating complex contours.

Significant Capital Investment

These systems are not simple machines. A vacuum press or furnace represents a significant capital expense due to the complexity of the vacuum pumps, control systems, and heating elements required to operate safely and effectively.

High Operational Complexity

Achieving and maintaining a high vacuum is a precise technical challenge. These systems demand skilled operators for programming process cycles and diligent maintenance to ensure the integrity of seals and pumps. The energy consumption is also considerable.

Making the Right Choice for Your Goal

Understanding the core purpose behind using a vacuum press allows you to identify the specific process that matters most for a given application.

- If your primary focus is maximum material strength and purity: You are leveraging the vacuum to eliminate oxides, enabling processes like vacuum sintering and hot pressing for mission-critical parts.

- If your primary focus is to join complex assemblies without distortion: You should look to vacuum brazing, which provides clean, flux-free joints that are often as strong as the parent material.

- If your primary focus is to create novel advanced materials: Vacuum hot pressing is the key process for combining dissimilar materials (like ceramic-metal composites) and achieving full density from powders.

Ultimately, the use of a vacuum press in any industry signals a commitment to engineering materials at the absolute peak of their potential performance.

Summary Table:

| Industry | Key Applications | Core Benefits |

|---|---|---|

| Aerospace | Turbine blades, structural elements | High strength, temperature resistance, purity |

| Medical | Surgical implants, prosthetics | Biocompatibility, sterility, no contamination |

| Electronics | Semiconductor wafers, microchips | Ultra-pure materials, precise electrical properties |

| Automotive | Gears, powertrain components | Wear resistance, reliability, high performance |

Unlock Peak Performance with KINTEK's Advanced Vacuum Solutions

Are you in aerospace, medical, electronics, or automotive industries and need to achieve superior material purity, strength, and precision? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact us today to discuss how our tailored vacuum press technologies can enhance your processes and deliver reliable, high-integrity results for your critical applications!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability