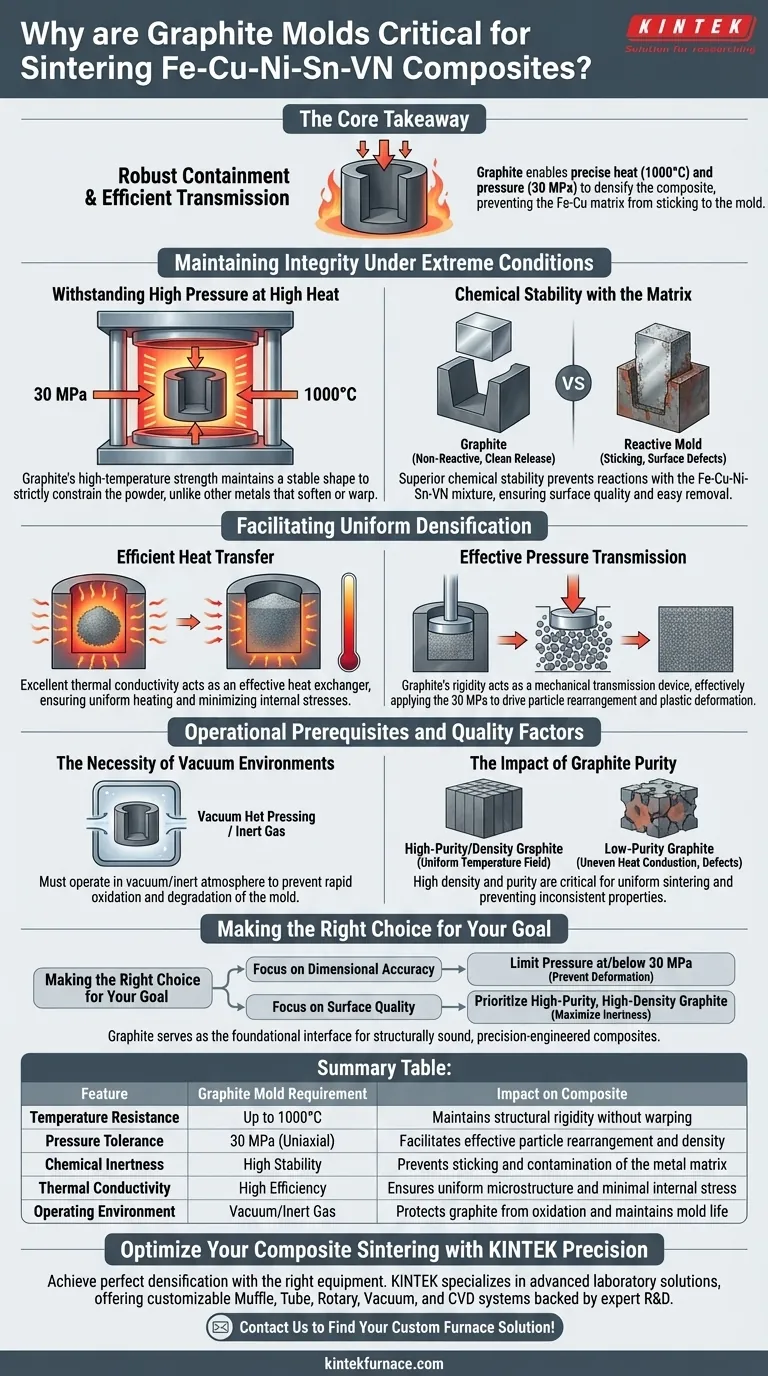

Graphite molds are the critical enabler for sintering Fe-Cu-Ni-Sn-VN composites because they maintain structural rigidity and chemical inertness where other materials would fail. Specifically, they withstand the simultaneous application of high thermal loads (up to 1000°C) and significant mechanical pressure (30 MPa) without deforming or contaminating the metal matrix.

The Core Takeaway Graphite acts as both a robust containment vessel and an efficient transmission medium. It allows for the precise application of heat and pressure necessary to densify the composite powder into a solid, high-strength material, while preventing the iron-copper matrix from sticking to the mold walls.

Maintaining Integrity Under Extreme Conditions

Withstanding High Pressure at High Heat

The sintering process for Fe-Cu-Ni-Sn-VN composites requires an aggressive environment to achieve proper density. The mold must withstand a uniaxial pressure of approximately 30 MPa while subjected to temperatures around 1000°C.

Most metallic molds would soften, warp, or lose strength under these combined conditions. Graphite, however, possesses excellent high-temperature strength. It maintains a stable shape to strictly constrain the powder, ensuring the final product meets precise dimensional specifications.

Chemical Stability with the Matrix

At sintering temperatures, metal powders become highly reactive. A major challenge in processing iron-copper (Fe-Cu) based matrices is preventing the sample from chemically bonding with the mold.

Graphite offers superior chemical stability in this context. It does not undergo severe chemical reactions with the Fe-Cu-Ni-Sn-VN mixture. This prevents "sticking," ensures the surface quality of the composite, and allows for easy removal of the finished part.

Facilitating Uniform Densification

Efficient Heat Transfer

Achieving a uniform microstructure requires that the entire powder volume reaches the sintering temperature simultaneously. Graphite has excellent thermal conductivity, which allows it to act as an effective heat exchanger.

It facilitates the uniform transfer of heat from the furnace elements to the internal powder sample. This uniformity is vital for minimizing thermal gradients that could lead to inconsistent mechanical properties or internal stresses within the composite.

Effective Pressure Transmission

Beyond defining the shape, the mold acts as a mechanical transmission device. The graphite punches must transfer the force from the press head directly to the powder.

Because graphite acts as a rigid medium, it ensures that the 30 MPa of pressure is applied effectively to the powder body. This mechanical force facilitates particle rearrangement and plastic deformation, driving the material from a loose powder state to a fully densified solid.

Operational Prerequisites and Quality Factors

The Necessity of Vacuum Environments

While graphite is chemically stable regarding the metal composite, it is sensitive to oxidation in air at high temperatures. The primary reference explicitly notes the use of vacuum hot pressing.

To utilize graphite molds effectively, the process must occur in a vacuum or inert atmosphere. Without this protection, the mold would rapidly degrade, compromising the structural integrity of the setup.

The Impact of Graphite Purity

Not all graphite is created equal. The density and purity of the mold material itself are critical variables.

High-density, high-purity graphite ensures a more uniform sintering temperature field. Variations in the mold's density can lead to uneven heat conduction, potentially causing inconsistent sintering across the composite sample.

Making the Right Choice for Your Goal

To maximize the quality of your Fe-Cu-Ni-Sn-VN composites, consider how the mold interacts with your specific processing targets:

- If your primary focus is Dimensional Accuracy: Ensure your process parameters do not exceed the specific compressive yield strength of the graphite grade chosen, maintaining pressure at or below 30 MPa to prevent mold deformation.

- If your primary focus is Surface Quality: Prioritize high-purity graphite with high density to maximize chemical inertness and ensure a smooth, non-reactive interface with the iron-copper matrix.

Graphite serves as the foundational interface that translates raw heat and force into a structurally sound, precision-engineered composite.

Summary Table:

| Feature | Graphite Mold Requirement | Impact on Fe-Cu-Ni-Sn-VN Composite |

|---|---|---|

| Temperature Resistance | Up to 1000°C | Maintains structural rigidity without warping |

| Pressure Tolerance | 30 MPa (Uniaxial) | Facilitates effective particle rearrangement and density |

| Chemical Inertness | High Stability | Prevents sticking and contamination of the metal matrix |

| Thermal Conductivity | High Efficiency | Ensures uniform microstructure and minimal internal stress |

| Operating Environment | Vacuum/Inert Gas | Protects graphite from oxidation and maintains mold life |

Optimize Your Composite Sintering with KINTEK Precision

Achieving the perfect densification for Fe-Cu-Ni-Sn-VN composites requires more than just high temperatures; it demands the right equipment and materials. KINTEK specializes in advanced laboratory solutions, offering a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems.

Backed by expert R&D and world-class manufacturing, our lab high-temp furnaces are fully customizable to meet your unique pressure and thermal requirements. Whether you are aiming for superior dimensional accuracy or perfect surface quality, our team is ready to provide the technical support you need.

Ready to elevate your material science research? Contact us today to find your custom furnace solution!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- How does a vacuum hot pressing furnace contribute to high-hardness composites? Achieve Near-Theoretical Density

- What is the core function of a vacuum hot press furnace? Achieve Near-Perfect Densification for Nano-Copper

- What are the core advantages of high-vacuum hot press sintering for Al2O3/TiC ceramics? Achieve Near-Theoretical Density

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What factors should be considered when selecting vacuum press equipment? Key Insights for Optimal Performance

- Why is an argon atmosphere required during SPS of Ti-6Al-4Zr-4Nb alloys? Protect Your High-Performance Titanium

- Why are pressure and temperature control crucial for Cu-CNT composites? Eliminate Delamination in Vacuum Hot Pressing

- What functions do graphite molds perform during vacuum hot press sintering? Discover their active role in densification