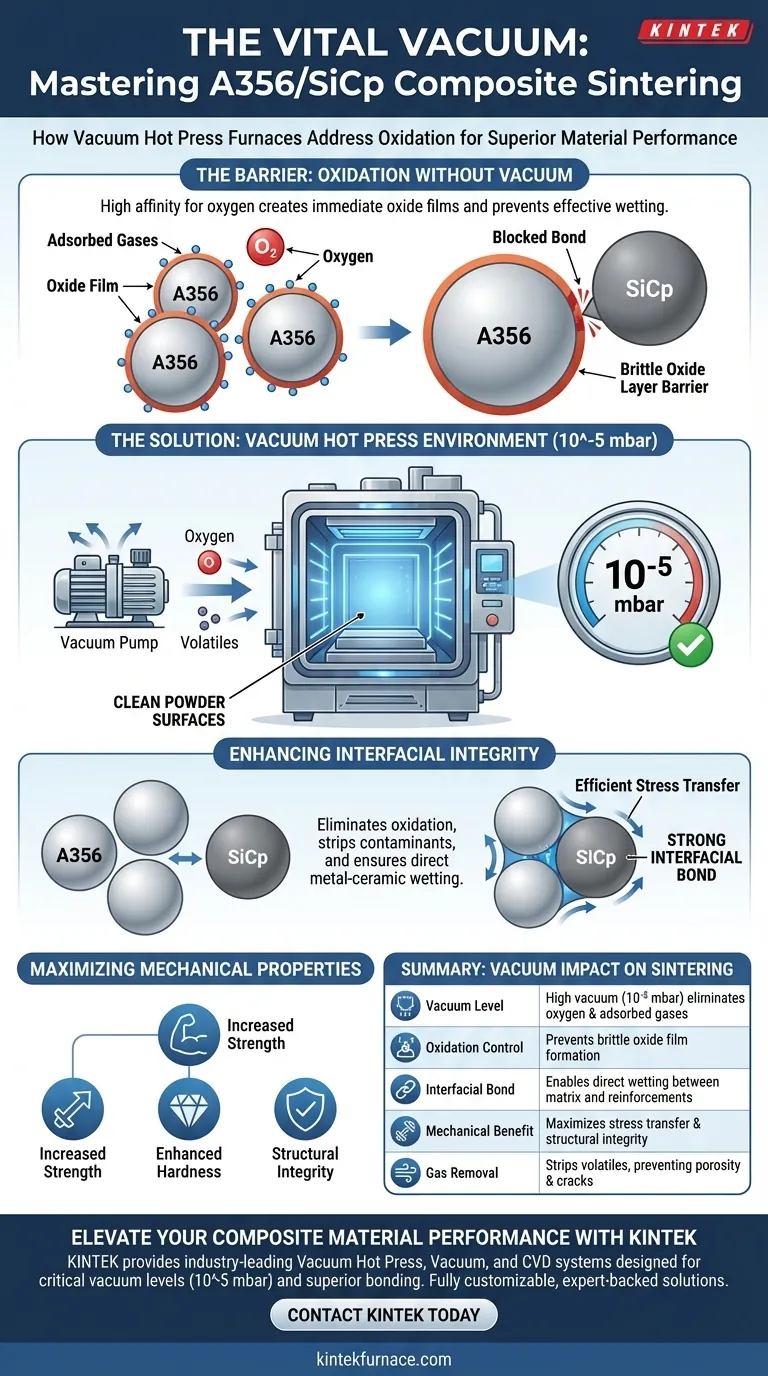

The primary issue addressed by the vacuum environment in a Vacuum Hot Press furnace is the oxidation of the aluminum alloy matrix (A356) at high sintering temperatures.

Because aluminum has a high affinity for oxygen, processing it without a vacuum would create an oxide film on the powder surfaces. The vacuum environment—typically reaching levels around 10^-5 mbar—eliminates oxygen and removes adsorbed gases, ensuring that the metal matrix can bond effectively with the silicon carbide (SiCp) reinforcement particles.

Core Insight By removing oxygen and volatile impurities, the vacuum environment prevents the formation of brittle oxide layers that act as barriers within the material. This purification is the prerequisite for creating a strong interfacial bond, which is the defining factor in the composite's final mechanical strength and structural integrity.

The Barrier of Oxidation

The Sensitivity of A356 Aluminum

The A356 alloy matrix is highly susceptible to oxidation when heated. If oxygen is present during sintering, the aluminum powder surfaces essentially rust instantly, forming a thin but stubborn oxide film.

Blocking the Bond

This oxide film acts as a physical barrier. It prevents the aluminum matrix from wetting and adhering to the Silicon Carbide (SiCp) particles. Without direct contact between the metal and the ceramic, the composite fails to act as a unified material.

Evacuating Adsorbed Gases

The issue is not just the air in the chamber; the raw powders themselves often carry adsorbed gases and volatiles on their surfaces. The vacuum environment actively strips these contaminants away before the material reaches critical sintering temperatures.

Enhancing Interfacial Integrity

Creating a Clean Interface

The vacuum environment functions as a purification step. By maintaining a pressure as low as 10^-5 mbar, the furnace ensures that the environment surrounding the composite is chemically inert.

Minimizing Harmful Reactions

Beyond simple oxidation, the vacuum minimizes complex, harmful interfacial reactions between the matrix and the reinforcements. This stability is crucial for maintaining the purity of the A356 alloy.

Maximizing Mechanical Properties

The ultimate goal of this "clean" processing is mechanical performance. When the oxide barrier is removed, a clean, strong interfacial bond forms. This allows stress to transfer efficiently from the ductile aluminum matrix to the rigid SiC particles, significantly enhancing the composite's strength and hardness.

Understanding the Trade-offs

Process Complexity vs. Material Quality

While the vacuum environment is essential for quality, it introduces complexity. Achieving and maintaining high vacuum levels (10^-5 mbar) requires sophisticated sealing and pumping systems, which increases the cycle time compared to non-vacuum methods.

The Necessity of "clean" Powders

The vacuum is effective, but it is not magic. It relies on the raw materials having a baseline level of purity. If the initial powder is heavily contaminated or pre-oxidized beyond what the vacuum can strip away, the resulting interface will still be compromised.

Making the Right Choice for Your Goal

If your primary focus is Maximum Mechanical Strength: Ensure your process maintains a high vacuum (10^-5 mbar) throughout the heating cycle to guarantee a defect-free, oxide-free interface between the A356 and SiCp.

If your primary focus is Microstructural Uniformity: Leverage the combination of vacuum and hot pressing to prevent porosity and gas entrapment, which eliminates defects that commonly lead to crack initiation.

The vacuum environment is not merely a feature of the furnace; it is the fundamental enabler that allows aluminum composites to achieve their theoretical performance limits.

Summary Table:

| Feature | Impact on A356/SiCp Sintering |

|---|---|

| Vacuum Level | High vacuum (approx. 10^-5 mbar) eliminates oxygen & adsorbed gases. |

| Oxidation Control | Prevents brittle oxide film formation on aluminum powder surfaces. |

| Interfacial Bond | Enables direct wetting between metal matrix and SiC reinforcements. |

| Mechanical Benefit | Maximizes stress transfer, hardness, and structural integrity. |

| Gas Removal | Strips volatiles to prevent porosity and internal crack initiation. |

Elevate Your Composite Material Performance

Achieving the theoretical strength of A356/SiCp composites requires more than just heat; it demands a contamination-free environment. KINTEK provides industry-leading Vacuum Hot Press, Vacuum, and CVD systems designed to reach the critical vacuum levels (10^-5 mbar) necessary to eliminate oxidation and ensure superior interfacial bonding.

Backed by expert R&D and precision manufacturing, our lab high-temp furnaces are fully customizable to meet your unique sintering and material synthesis needs.

Ready to optimize your sintering process? Contact KINTEK today to discuss your custom furnace solution with our technical experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does a vacuum hot press furnace benefit sintering experiments? Achieve Superior Material Density and Purity

- How does a Vacuum Hot Pressing (VHP) furnace prepare high-performance P-type Mg3Sb2 thermoelectric materials?

- What is the application of hot press furnaces in ceramic processing? Achieve Superior Density and Strength

- How does the capability for long-duration temperature control in a vacuum hot pressing furnace improve ZnS ceramics?

- Why is it necessary to maintain a high vacuum environment during the SPS of SiC? Key to High-Density Ceramics

- How does a precision pressure control system assist in material formation during Eutectic Bonding?

- How does graphite felt function as an insulation material in FAST equipment? Boost Efficiency & Thermal Uniformity

- What medical applications benefit from Vacuum Hot Press technology? Enhance Biocompatible Implants and Tools