Maintaining a high vacuum environment during Spark Plasma Sintering (SPS) is critical for preventing material degradation and ensuring structural integrity. It primarily serves to eliminate adsorbed gases that cause porosity while shielding both the silicon carbide (SiC) powder and graphite tooling from destructive oxidation at elevated temperatures.

Core Takeaway A high vacuum does more than just remove air; it actively purifies grain boundaries and protects the sintering system. By preventing oxidation and evacuating volatiles, it allows SiC ceramics to achieve densities close to their theoretical limit with superior mechanical properties.

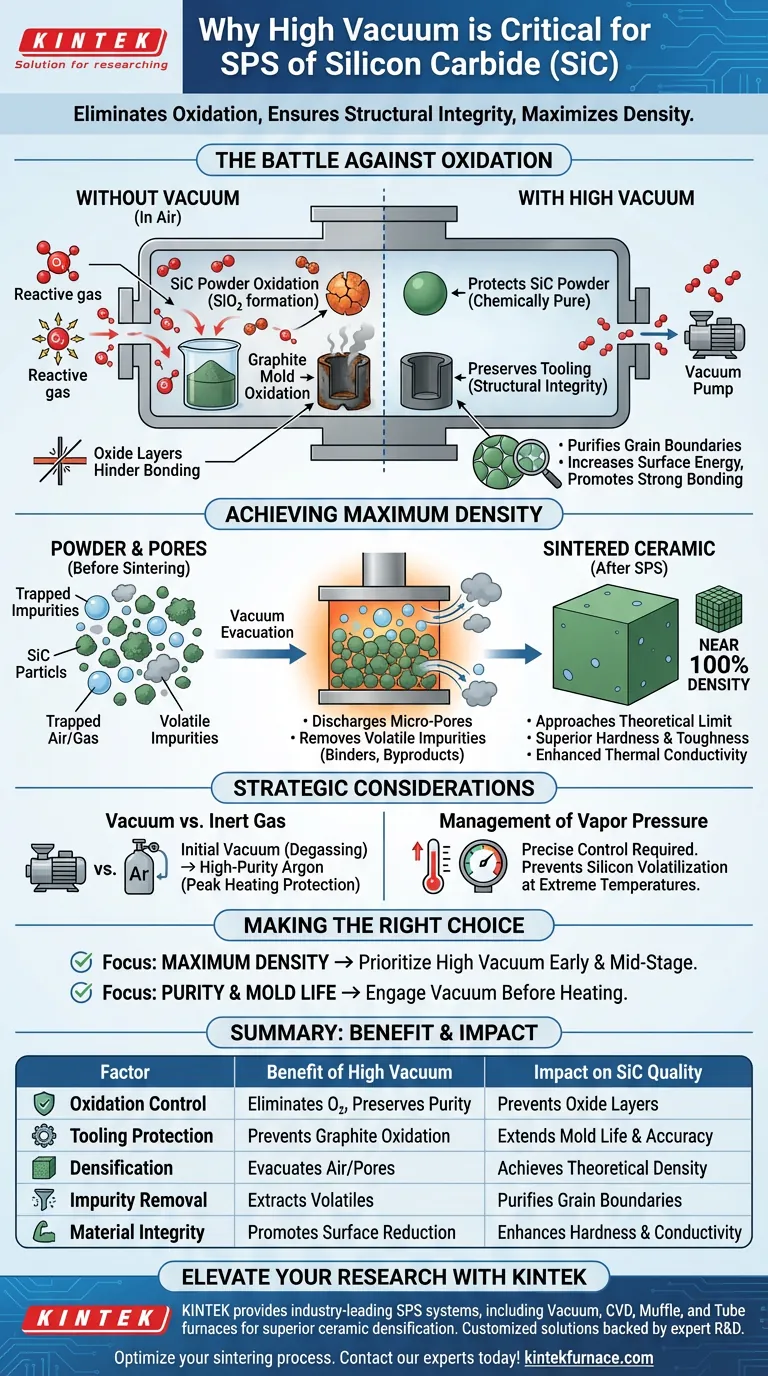

The Battle Against Oxidation

Protecting the Raw Material

Silicon carbide (SiC) powder is highly susceptible to oxidation when exposed to high temperatures in the presence of oxygen.

Maintaining a vacuum removes oxygen from the chamber, ensuring the SiC powder retains its chemical purity. This prevents the formation of unwanted oxide layers on the particle surfaces, which would otherwise degrade the mechanical performance of the final ceramic.

Preserving the Tooling

SPS typically utilizes graphite molds to contain the powder and conduct the pulsed current.

Graphite oxidizes rapidly in air at sintering temperatures. A high vacuum environment is essential to protect these molds from oxidative wear, preserving their structural integrity and ensuring the dimensional accuracy of the final sintered part.

Purifying Grain Boundaries

Raw powder particles often possess surface oxides or adsorbed impurities that hinder bonding.

The vacuum environment promotes the volatilization or reduction of these surface layers. This "cleaning" effect increases surface energy and purifies the grain boundaries, creating the ideal conditions for particles to bond strongly during densification.

Achieving Maximum Density

Evacuating Micro-Pores

For a ceramic to be strong, it must be dense. Air trapped between powder particles acts as a barrier to densification.

A high vacuum effectively discharges micro-pores and evacuates air from the interstices between powder particles. This removal of trapped gas reduces sintering resistance, allowing the material to compact more efficiently.

Removing Volatile Impurities

Beyond air, the sintering process often involves the release of gases from organic binders or volatile reaction byproducts.

Vacuum systems are particularly effective at extracting these volatiles, especially during lower-temperature stages (e.g., below 400°C). Removing these contaminants prevents the formation of closed pores or bubbles inside the material.

Approaching the Theoretical Limit

By eliminating both physical gas barriers and chemical oxide barriers, the sintering process becomes highly efficient.

This allows the final silicon carbide ceramic to achieve an extremely high density, approaching its theoretical limit. High density is the decisive factor for maximizing hardness, fracture toughness, and thermal conductivity.

Understanding the Trade-offs

Vacuum vs. Inert Gas Protection

While vacuum is critical for degassing, it is not always the sole atmosphere used throughout the entire cycle.

For certain processes, a vacuum is used initially to remove binders and impurities, followed by the introduction of high-purity Argon. This inert gas can provide additional protection against decomposition or oxidation during the peak heating stages, offering a balanced approach to atmosphere control.

Management of Vapor Pressure

In extreme high-temperature scenarios, maintaining a vacuum requires careful management.

While vacuum prevents oxidation, excessively low pressure at very high temperatures can theoretically induce the decomposition or volatilization of certain silicon-based constituents. Therefore, precise control of the vacuum level is required to balance purification against material stability.

Making the Right Choice for Your Goal

To optimize your SiC sintering process, align your atmospheric control with your specific objectives:

- If your primary focus is Maximum Density: Prioritize a high vacuum during the early and intermediate stages to ensure complete evacuation of micro-pores and adsorbed gases.

- If your primary focus is Purity and Mold Life: Ensure the vacuum system is engaged before heating begins to strictly prevent oxygen exposure to the graphite tooling and SiC powder.

Ultimately, the vacuum environment is the invisible tool that transforms loose powder into a solid, high-performance engineering ceramic.

Summary Table:

| Factor | Benefit of High Vacuum | Impact on SiC Quality |

|---|---|---|

| Oxidation Control | Eliminates oxygen in the chamber | Preserves chemical purity & prevents oxide layers |

| Tooling Protection | Prevents graphite mold oxidation | Extends mold life & ensures dimensional accuracy |

| Densification | Evacuates air from micro-pores | Achieves density near theoretical limits |

| Impurity Removal | Extracts volatiles & adsorbed gases | Purifies grain boundaries for stronger bonding |

| Material Integrity | Promotes surface layer reduction | Enhances hardness and thermal conductivity |

Elevate Your Advanced Material Research with KINTEK

Precision sintering of Silicon Carbide requires absolute control over atmospheric conditions. KINTEK provides industry-leading Spark Plasma Sintering (SPS) systems, including Vacuum, CVD, Muffle, and Tube furnaces, all engineered to deliver the high-vacuum environments necessary for superior ceramic densification.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to meet your unique laboratory or production needs. Don't let oxidation or porosity compromise your results.

Ready to optimize your sintering process? Contact us today to consult with our experts!

Visual Guide

References

- Zipeng Li, Zhiqing Liang. Preparation of Aluminum Matrix Composites Reinforced with Hybrid MAX–MXene Particles for Enhancing Mechanical Properties and Tribological Performance. DOI: 10.3390/jcs9100552

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does the uniaxial pressure applied by a vacuum hot press furnace affect the microstructure of ZrC-SiC materials?

- How do graphite molds function during the SPS of Ti-6Al-4Zr-4Nb alloys? Mastering Dual-Action Sintering

- How does the hot pressing mechanism enhance TiB2-TiN density? Achieve Superior Hardness in Tool Materials

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What is the primary function of the vacuum environment in a vacuum hot press furnace during titanium alloy processing? Prevent Embrittlement for Superior Ductility

- Why is a high-vacuum sintering system necessary for SPS of Al2O3-TiC? Unlock Maximum Density & Hardness

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the role of sacrificial inserts in the Spark Plasma Sintering (SPS) process? Master Complex Geometry Design