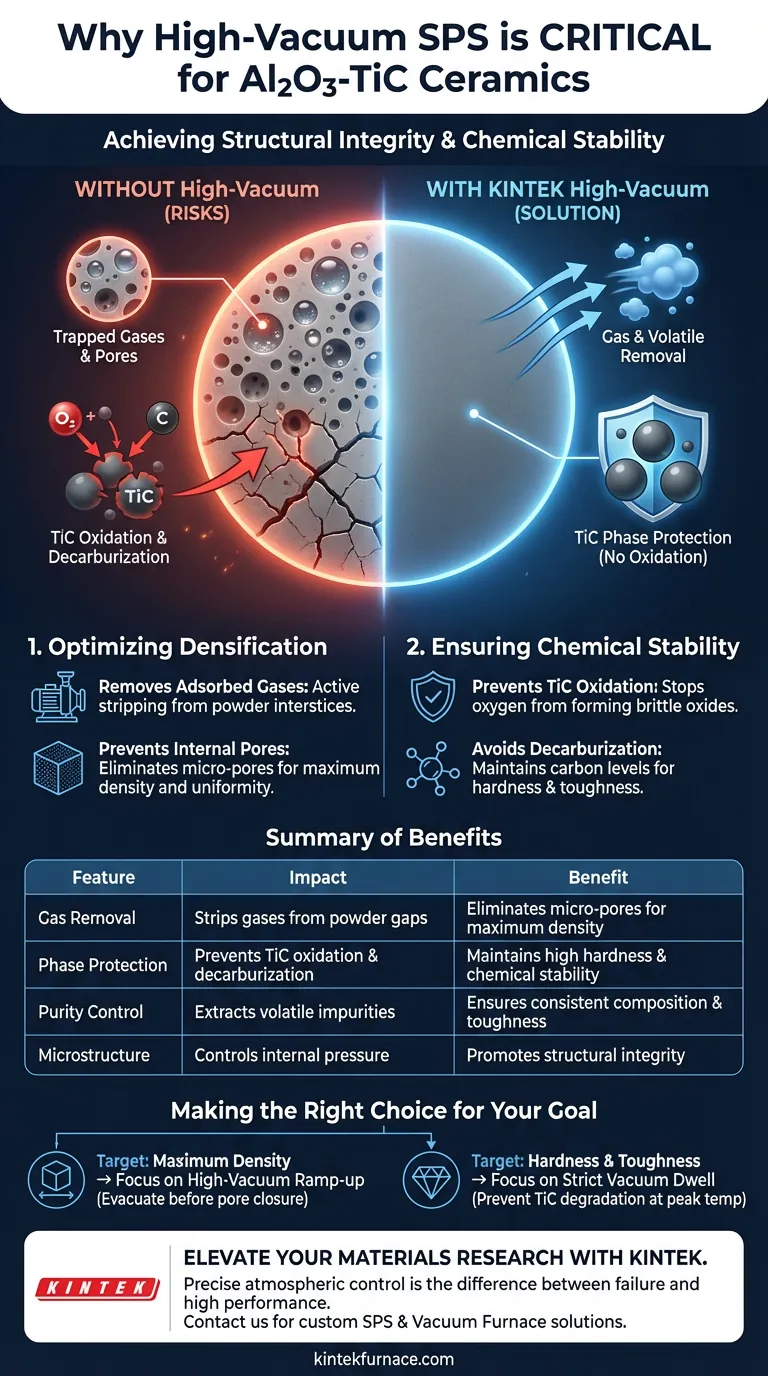

Achieving structural integrity in Al2O3-TiC ceramics requires a high-vacuum sintering system. This environment is critical for extracting adsorbed gases and volatile impurities from the powder interstices, which is necessary to prevent internal pore formation. Additionally, the vacuum protects the Titanium Carbide (TiC) phase from oxidation and decarburization, preserving the composite's chemical stability and mechanical performance.

The vacuum environment serves a dual purpose: it acts as a purification mechanism by removing trapped gases to minimize porosity, and as a protective shield that preserves the chemical integrity of the titanium carbide phase against high-temperature degradation.

Optimizing Densification and Microstructure

To achieve a dense ceramic body, you must address the physical barriers inherent in the powder compact.

Removing Adsorbed Gases

Raw ceramic powders naturally hold adsorbed gases on their surfaces. A high-vacuum environment actively strips these gases from the powder gaps before and during the heating process. Failure to remove these gases would result in trapped pockets of air within the material.

Preventing Internal Pores

The presence of volatile impurities creates internal pressure that opposes densification. By maintaining a low-pressure environment, you facilitate the extraction of these volatiles. This results in a significant reduction of micro-pores, ensuring the final product achieves high density and structural uniformity.

Ensuring Chemical Stability

While Aluminum Oxide (Al2O3) is relatively stable, the Titanium Carbide (TiC) component introduces specific chemical vulnerabilities at sintering temperatures.

Preventing TiC Oxidation

Titanium Carbide is highly susceptible to oxidation when exposed to high temperatures. Even trace amounts of residual oxygen can react with TiC to form titanium oxides. The vacuum system eliminates oxygen from the chamber, ensuring the TiC remains in its hard, non-oxide phase.

Avoiding Decarburization

High temperatures can lead to the loss of carbon from the TiC structure, a process known as decarburization. This reaction alters the stoichiometry of the ceramic, weakening its mechanical properties. A controlled vacuum environment suppresses this reaction, maintaining the hardness and toughness required for high-performance applications.

The Risks of Inadequate Vacuum Control

While a vacuum system adds complexity, operating without one or with insufficient vacuum levels introduces severe performance penalties.

Compromised Mechanical Properties

If oxidation occurs, the formation of oxide impurities will degrade the material's hardness. Instead of a robust Al2O3-TiC composite, you risk creating a material with brittle oxide inclusions that act as failure points.

Inconsistent Phase Composition

Without precise atmospheric control, chemical reactions become unpredictable. The final sintered body may not match the intended phase composition. This leads to variability in performance, making the ceramic unsuitable for precision tooling or structural applications.

Making the Right Choice for Your Goal

The level of vacuum control you implement should align with the specific properties you need to maximize in your final product.

- If your primary focus is Maximum Density: Prioritize a high-vacuum ramp-up stage to ensure all adsorbed gases are evacuated from powder gaps before pore closure occurs.

- If your primary focus is Hardness and Toughness: Maintain a strict high-vacuum or oxygen-free environment throughout the peak temperature dwell to prevent the degradation of the TiC phase.

Success in SPS processing relies on viewing the vacuum not just as an absence of air, but as an active tool for chemical and structural control.

Summary Table:

| Feature | Impact of High Vacuum | Benefit to Al2O3-TiC Composite |

|---|---|---|

| Gas Removal | Strips adsorbed gases from powder gaps | Eliminates micro-pores for maximum density |

| Phase Protection | Prevents TiC oxidation & decarburization | Maintains high hardness and chemical stability |

| Purity Control | Facilitates extraction of volatile impurities | Ensures consistent phase composition and toughness |

| Microstructure | Controls internal pressure during heating | Promotes structural integrity and uniform densification |

Elevate Your Materials Research with KINTEK

Precise atmospheric control is the difference between a brittle failure and a high-performance ceramic. Backed by expert R&D and manufacturing, KINTEK offers specialized Spark Plasma Sintering (SPS) support and high-temperature vacuum systems, including Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to your unique sintering requirements.

Don't let oxidation or porosity compromise your results. Partner with KINTEK to achieve the structural integrity and mechanical excellence your Al2O3-TiC composites demand.

Contact our technical experts today to find your custom sintering solution.

Visual Guide

References

- Huda F. Khalil, Mervette El-Batouti. Zn-Al Ferrite/Polypyrrole Nanocomposites: Structure and Dielectric and Magnetic Properties for Microwave Applications. DOI: 10.3390/polym16172432

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the technical advantages of Vacuum SPS systems for large transparent ceramics? Achieve Peak Optical Clarity

- What are the advantages of a high-pressure vacuum induction hot press furnace? Boost SiGe Thermoelectric Performance

- What role does a Spark Plasma Sintering (SPS) system play in the preparation of Al0.3CoCrFeNiMo0.75 bulk materials?

- Why is a high vacuum environment crucial when preparing copper-carbon nanotube composites in a vacuum hot press furnace? Achieve Superior Composite Integrity

- How have vacuum hot press furnaces transformed material processing? Achieve Superior Density and Purity

- What is the role of the vacuum environment in SiC/ZTA sintering? Enhance Densification & Material Purity

- What role does a vacuum hot press play in the consolidation of metallic glass powders? Expert Consolidation Insights

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision