At their core, vacuum hot press furnaces have transformed material processing by combining three critical elements—high temperature, high pressure, and a controlled vacuum—into a single, synergistic process. This unique capability allows for the fabrication of advanced materials with near-perfect density and superior mechanical properties, which is impossible to achieve with conventional heating or pressing methods alone.

The true innovation of a vacuum hot press is not just the application of heat or pressure, but the simultaneous control of both in an environment free of atmospheric contaminants. This synergy overcomes fundamental material limitations, enabling the creation of stronger, purer, and more complex components.

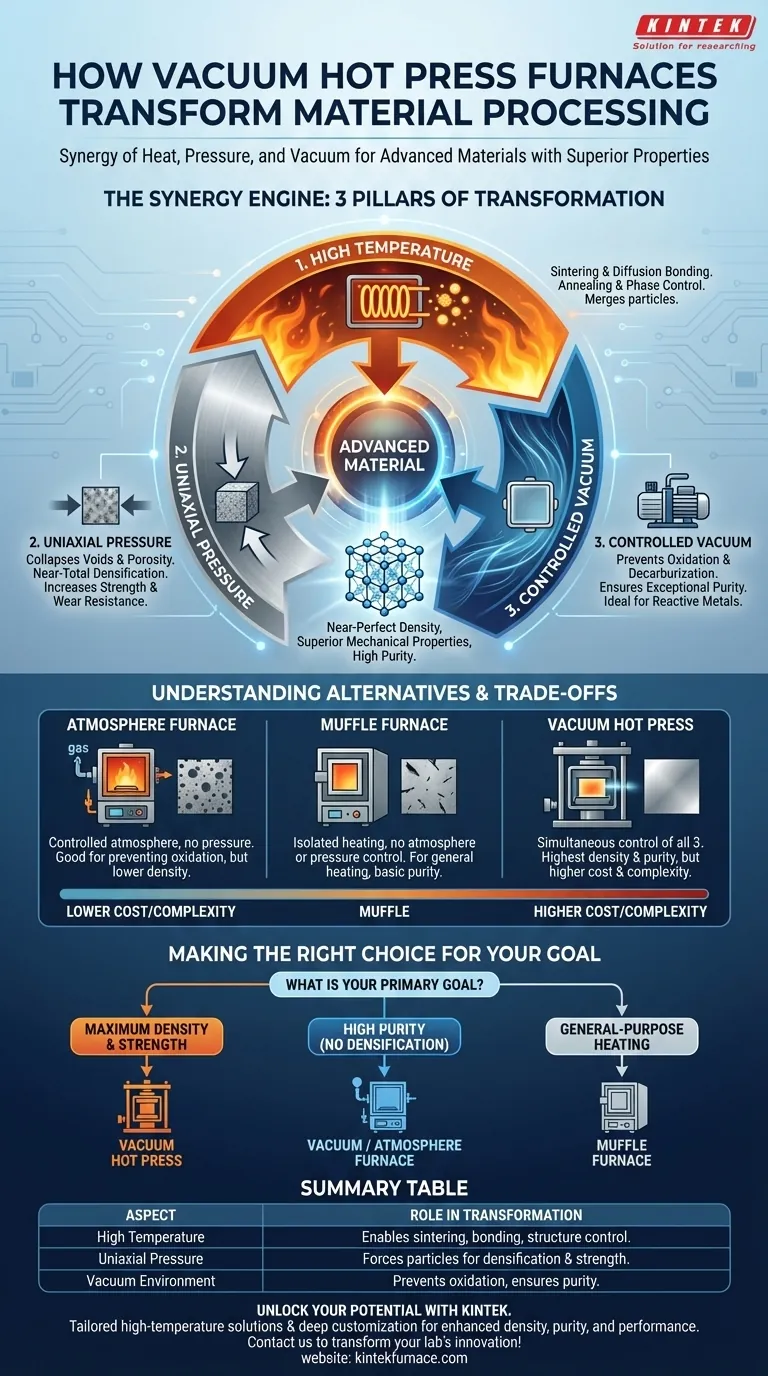

The Pillars of Transformation: Heat, Pressure, and Vacuum

The revolutionary impact of vacuum hot pressing stems from how it precisely manipulates three physical factors. Each plays a distinct and crucial role in altering a material's fundamental structure.

The Role of High Temperature

High temperature provides the necessary thermal energy to initiate critical processes like sintering and diffusion bonding. This allows individual material particles to merge and bond, reducing internal gaps.

Temperature control is also essential for annealing and managing phase transformations within the material, allowing engineers to fine-tune its final crystal structure and properties.

The Force of Uniaxial Pressure

While heat encourages particles to bond, high pressure physically forces them together. This mechanical force is critical for collapsing internal voids and porosity that heat alone cannot eliminate.

The result is a material with near-total densification. This is the primary mechanism for dramatically increasing a material's hardness, wear resistance, and overall mechanical strength.

The Power of Vacuum

The vacuum environment is the unsung hero of the process. By removing air and other gases, it completely prevents oxidation and decarburization, especially when working with reactive metals and alloys.

This ensures the final product has exceptional purity, which is vital for applications in electronics, medical implants, and advanced research where even minor contamination can cause catastrophic failure.

Understanding the Trade-offs and Alternatives

While powerful, a vacuum hot press is a specialized tool. Understanding its place among other thermal processing technologies is key to appreciating its specific advantages.

Versus Atmosphere Furnaces

Atmosphere furnaces also provide a controlled, oxygen-free environment for heat treatment. However, they lack the integrated high-pressure system.

They are excellent for preventing oxidation during sintering or annealing but cannot achieve the same level of densification as a hot press. They are a suitable choice when density is not the primary concern.

Versus Muffle Furnaces

Muffle furnaces are simpler devices that isolate the material from heating elements, preventing direct contamination from combustion byproducts. They offer good temperature uniformity for general heat-treating.

However, they provide no control over the atmosphere (unless purged with a gas) and offer no pressure capabilities. They are best suited for basic applications where atmospheric purity and densification are non-critical.

The Primary Trade-off: Cost and Complexity

The main drawback of vacuum hot press technology is its significant cost and operational complexity compared to simpler furnaces. The systems required to generate and maintain high vacuum, high pressure, and high temperature simultaneously are inherently sophisticated and expensive.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on the desired properties of your final material. Your decision should be driven by the specific engineering problem you need to solve.

- If your primary focus is achieving maximum density and mechanical strength: A vacuum hot press is unparalleled, as the combination of pressure and heat is essential for eliminating porosity.

- If your primary focus is high-purity heat treatment without densification: A standard vacuum furnace or a controlled atmosphere furnace provides the necessary protection from oxidation at a lower cost.

- If your primary focus is general-purpose heating or ashing: A muffle furnace offers a reliable and cost-effective solution when precise atmospheric control is not a requirement.

Ultimately, understanding the unique interplay of heat, pressure, and vacuum is the key to leveraging this technology for next-generation material innovation.

Summary Table:

| Aspect | Role in Transformation |

|---|---|

| High Temperature | Enables sintering, diffusion bonding, and phase transformations for material bonding and structure control. |

| Uniaxial Pressure | Forces particles together to eliminate voids, achieving near-total densification and enhanced mechanical strength. |

| Vacuum Environment | Prevents oxidation and decarburization, ensuring high material purity for sensitive applications. |

| Key Advantages | Superior density, mechanical properties, and purity compared to conventional methods. |

Unlock the full potential of your material processing with KINTEK's advanced vacuum hot press furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering enhanced density, purity, and performance. Contact us today to discuss how our expertise can transform your projects and drive innovation in your lab!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction