The hot pressing mechanism enhances density by applying external mechanical pressure simultaneously with high-temperature heating. This combination acts directly on the powder particles to significantly increase the sintering driving force. It mechanically compels particle rearrangement and induces plastic flow, effectively eliminating internal pores and micro-cracks that thermal energy alone cannot resolve.

Core Takeaway TiB2 and TiN are ceramic materials characterized by strong covalent bonds and low self-diffusion coefficients, making them notoriously difficult to densify using heat alone. Vacuum hot pressing overcomes this inherent resistance by physically forcing particles to fill voids, achieving near-theoretical density and superior hardness where standard pressureless sintering fails.

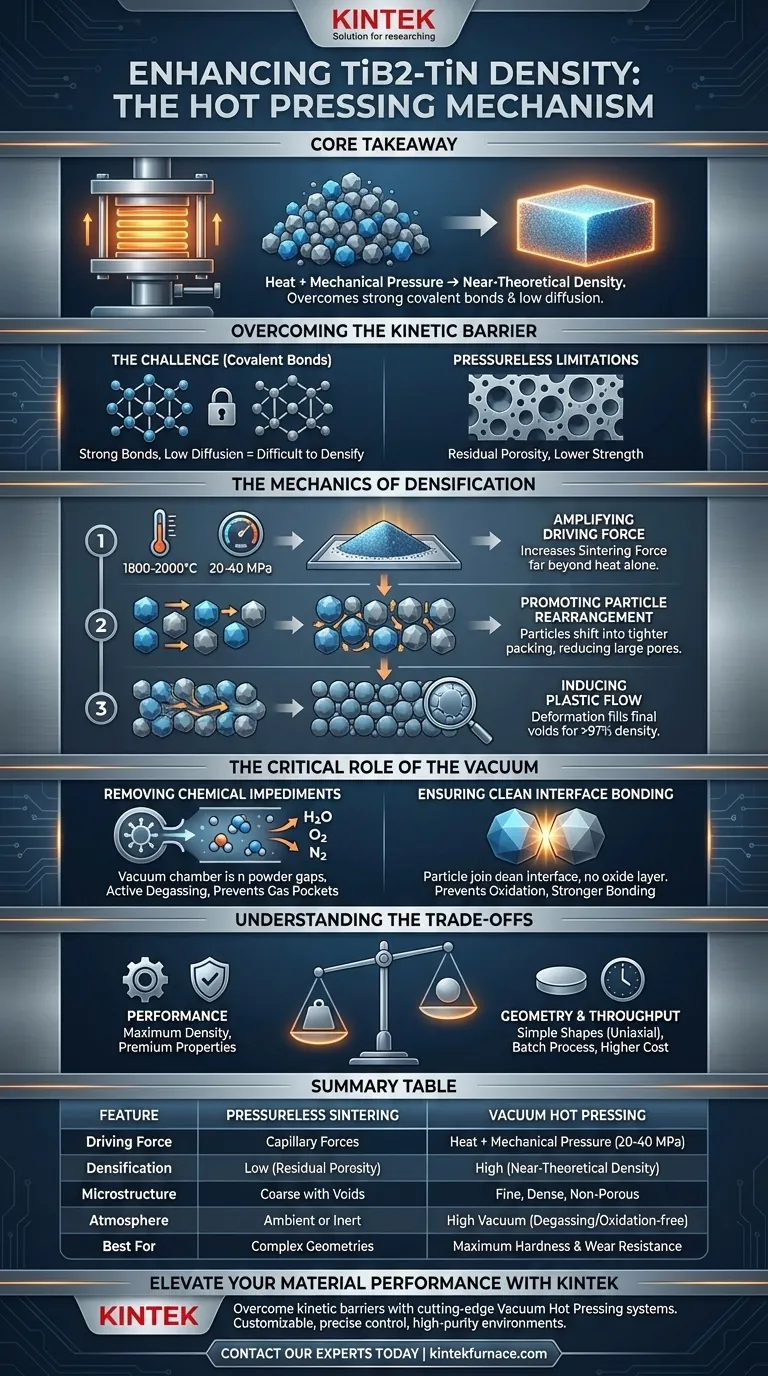

Overcoming the Kinetic Barrier

The Challenge of Covalent Bonds

TiB2 (Titanium Diboride) and TiN (Titanium Nitride) possess extremely strong covalent bonds. This atomic structure results in low diffusion coefficients, meaning atoms do not easily move or bond across particle boundaries even at high temperatures.

Limitations of Pressureless Sintering

In standard sintering, densification relies solely on surface energy reduction and capillary forces. Due to the low diffusion rates of these materials, pressureless methods often leave residual porosity, resulting in lower density and compromised mechanical strength.

The Mechanics of Densification

Amplifying the Driving Force

The vacuum hot press furnace introduces a critical variable: external mechanical pressure (often 20–40 MPa). This pressure acts alongside heat (1800–2000°C) to dramatically increase the sintering driving force, accelerating the consolidation process far beyond what temperature can achieve alone.

Promoting Particle Rearrangement

As the mechanical pressure is applied, powder particles are physically forced to slide past one another. They shift into tighter packing configurations, filling the gaps between larger particles and significantly reducing the volume of large pores early in the cycle.

Inducing Plastic Flow

At peak temperatures, the material softens slightly, allowing the applied pressure to deform the particles. This plastic flow forces material into the remaining microscopic voids and closed pores, eliminating the final traces of porosity to achieve densities often exceeding 97%.

The Critical Role of the Vacuum

Removing Chemical Impediments

The vacuum environment (e.g., 0.01 MPa) is essential for removing harmful gases like water vapor, oxygen, and nitrogen trapped in the powder gaps. This promotes active degassing, preventing gas pockets from becoming trapped inside the material as it densifies.

Ensuring Clean Interface Bonding

By preventing oxidation and carburization, the vacuum ensures the surfaces of the metal and ceramic particles remain clean. This purity facilitates a stronger microscopic interface bond between particles, directly contributing to the tool's final hardness and fracture toughness.

Understanding the Trade-offs

Geometry Limitations

Vacuum hot pressing typically applies uniaxial pressure (force from one direction). This generally limits the production of parts to simple geometric shapes, such as plates or discs, requiring additional machining for complex tool geometries.

Throughput vs. Performance

This is a batch process that cannot match the speed of continuous sintering methods. The high cost of operation and longer cycle times are justified only when the application demands maximum density and premium mechanical properties.

Making the Right Choice for Your Goal

- If your primary focus is maximum hardness and wear resistance: Rely on vacuum hot pressing to eliminate micro-cracks and achieve the near-theoretical density required for high-performance cutting tools.

- If your primary focus is complex part geometry: Acknowledge that hot pressing produces simple shapes; you must account for the cost of post-sintering machining (EDM or grinding) to achieve the final tool shape.

Ultimately, the synergy of heat and pressure turns the inherent stubbornness of TiB2-TiN materials into a dense, non-porous microstructure capable of withstanding extreme industrial demands.

Summary Table:

| Feature | Pressureless Sintering | Vacuum Hot Pressing |

|---|---|---|

| Driving Force | Capillary forces only | Heat + Mechanical Pressure (20-40 MPa) |

| Densification | Low (Residual Porosity) | High (Near-Theoretical Density) |

| Microstructure | Coarse with voids | Fine, dense, non-porous |

| Atmosphere | Ambient or inert gas | High Vacuum (Degassing/Oxidation-free) |

| Best For | Complex geometries | Maximum hardness & wear resistance |

Elevate Your Material Performance with KINTEK

Are you struggling to densify stubborn ceramic composites like TiB2-TiN? KINTEK provides the cutting-edge technology required to overcome kinetic barriers and achieve superior material properties.

Backed by expert R&D and world-class manufacturing, we offer high-performance Vacuum Hot Pressing systems, alongside Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to meet your unique laboratory or industrial needs. Our systems ensure precise pressure control and high-purity vacuum environments to eliminate porosity and maximize the fracture toughness of your tools.

Ready to optimize your sintering process? Contact our experts today to find the perfect high-temperature solution for your application.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What functions do graphite molds perform during vacuum hot press sintering? Discover their active role in densification

- What role does a vacuum hot press furnace play in the densification of nanocomposites? Achieve Near-Theoretical Density

- How does a Vacuum Hot Press (VHP) furnace facilitate the fabrication of bulk nanostructured Al-4Cu alloys?

- What is the role of HIP equipment in the diffusion bonding of 6061 aluminum alloy? Achieve High-Integrity Metallurgy

- What are the advantages of using a vacuum hot press sintering furnace for preparing high-density carbon nanotube reinforced copper matrix composites? Achieve Maximum Density and Purity for Superior Performance

- What role do vacuum hot press furnaces play in research and development laboratories? Unlock Next-Gen Material Innovations

- How does vacuum hot press sintering compare to SPS for Fe-Cu composites? Achieve Superior Industrial Quality

- What are the main advantages of hot pressing in powder metallurgy? Achieve High-Density, Fine-Grained Components