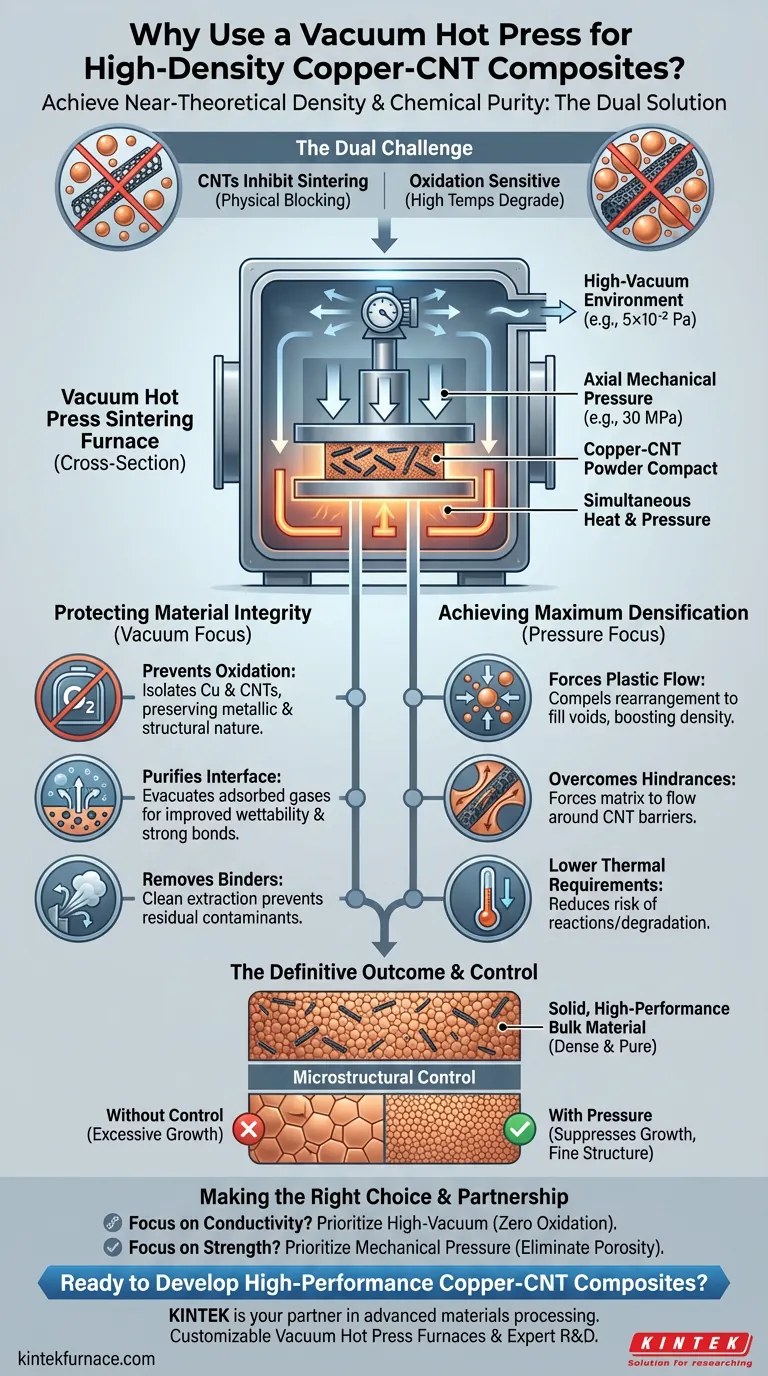

The primary advantage of using a vacuum hot press sintering furnace for Carbon Nanotube (CNT) reinforced copper composites is the ability to achieve near-theoretical density while maintaining chemical purity. By applying uniaxial mechanical pressure simultaneously with heat in a high-vacuum environment, this method overcomes the natural tendency of CNTs to inhibit sintering, forcing particle contact and preventing the oxidation that destroys electrical and mechanical performance.

Core Takeaway

Preparing copper-CNT composites presents a dual challenge: the reinforcements physically block densification, and the constituents are highly sensitive to oxidation. Vacuum hot pressing solves both simultaneously by using mechanical force to crush voids and a vacuum atmosphere to ensure the interface between the copper and the nanotube remains clean and bonded.

Protecting Material Integrity

The chemical stability of both the matrix (copper) and the reinforcement (CNTs) is the foundation of high-performance composites. The vacuum environment is not merely a feature; it is a chemical necessity.

Prevention of Oxidation

High temperatures usually trigger rapid oxidation in copper. Similarly, carbon nanotubes can degrade or "burn off" in oxygen-rich environments. The high-vacuum environment (e.g., 5×10⁻² Pa) completely isolates the materials from oxygen, preserving the metallic nature of the copper and the structural integrity of the CNTs.

Purification of the Interface

To achieve strength, the copper must bond tightly to the CNTs. Vacuum sintering effectively evacuates adsorbed gases and volatile impurities from the powder interstices. This "cleaning" of the surface improves wettability, ensuring a strong interfacial bond free from brittle oxide inclusions or reaction products.

Removal of Binders

If the powder mixture utilizes wax binders for shaping, the vacuum facilitates their effective extraction during the initial heating stages. This prevents residual carbon or contaminants from becoming trapped inside the final composite, which would otherwise weaken the material.

Achieving Maximum Densification

Carbon nanotubes have a high aspect ratio and rigidity, which naturally hinders the sintering process by stopping copper grains from growing together (a phenomenon known as "pinning"). Thermal energy alone is often insufficient to overcome this.

Forcing Plastic Flow

The furnace applies axial mechanical pressure (often around 30 MPa) directly to the powder. This external force compels the copper particles to undergo plastic flow and rearrangement. This forcibly fills the voids between particles that thermal diffusion alone cannot eliminate.

Overcoming Sintering Hindrances

CNTs typically act as barriers to the growth of "sintering necks" (the bridges between particles). The application of simultaneous pressure allows the material to overcome this hindrance, forcing the copper matrix to flow around the CNTs and achieve high density.

Lowering Thermal Requirements

Because mechanical pressure assists the densification, the process can often be completed at relatively lower temperatures compared to pressureless sintering. This is critical because lower temperatures reduce the risk of excessive chemical reactions that could degrade the CNTs.

Microstructural Control

The physical properties of the composite are defined by its microstructure. Vacuum hot pressing offers precise control over grain dynamics.

Suppression of Grain Growth

High temperatures held for long periods can cause copper grains to grow excessively large, which reduces material strength. The pressure-assisted mechanism accelerates densification, effectively suppressing excessive grain growth. This preserves a finer grain structure, which contributes to superior mechanical properties.

Understanding the Trade-offs

While vacuum hot pressing is highly effective for density and purity, it is important to recognize its operational context compared to other technologies.

Process Speed vs. Field-Assisted Methods

While hot pressing is efficient, technologies like SPS (Spark Plasma Sintering) utilize pulsed current to generate internal Joule heat for even faster heating rates. Consequently, standard vacuum hot pressing may have longer cycle times than SPS, potentially exposing materials to high temperatures for longer durations, which requires careful parameter control to avoid interface reactions.

Geometric Limitations

The application of uniaxial mechanical pressure generally limits the geometry of the final product to simple shapes (discs, cylinders, or plates). Unlike pressureless sintering or casting, this method is not suitable for creating complex, net-shape components without subsequent machining.

Making the Right Choice for Your Goal

To maximize the potential of your copper-CNT composite, align your processing parameters with your specific performance targets:

- If your primary focus is Electrical Conductivity: Prioritize the high-vacuum capability to ensure zero oxidation of the copper matrix, as even minor oxides act as insulators.

- If your primary focus is Mechanical Strength: Rely on the axial mechanical pressure to eliminate porosity, as voids are the primary initiation points for structural failure.

The vacuum hot press sintering furnace remains the definitive tool for converting loose copper-CNT powders into a solid, high-performance bulk material where density and purity are non-negotiable.

Summary Table:

| Key Advantage | Primary Benefit |

|---|---|

| High-Vacuum Environment | Prevents oxidation, removes impurities, and ensures a clean, strong interface between copper and CNTs. |

| Axial Mechanical Pressure | Forces plastic flow and particle rearrangement to achieve near-theoretical density, overcoming CNT hindrance. |

| Lower Sintering Temperature | Reduces thermal exposure, minimizing the risk of CNT degradation and excessive grain growth. |

| Microstructural Control | Suppresses excessive grain growth, preserving a fine grain structure for superior mechanical strength. |

Ready to Develop High-Performance Copper-CNT Composites?

Achieving maximum density and chemical purity is critical for the electrical and mechanical performance of your advanced composites. The challenges of CNT reinforcement and oxidation sensitivity require a precise and controlled sintering process.

KINTEK is your partner in advanced materials processing. Backed by expert R&D and manufacturing, KINTEK offers Vacuum Hot Press Sintering Furnaces and other lab high-temp systems, all customizable for your unique research and production needs.

Let us help you unlock the full potential of your materials.

Contact our experts today to discuss how our solutions can enhance your composite development.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the primary application fields for box furnaces and vacuum furnaces? Choose the Right Furnace for Your Process

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing