In short, vacuum hot press furnaces are indispensable tools in research and development for creating and testing next-generation materials. By simultaneously applying precise heat and mechanical pressure within a controlled vacuum, they allow scientists to synthesize novel materials like advanced ceramics, alloys, and composites that would be impossible to create under normal atmospheric conditions.

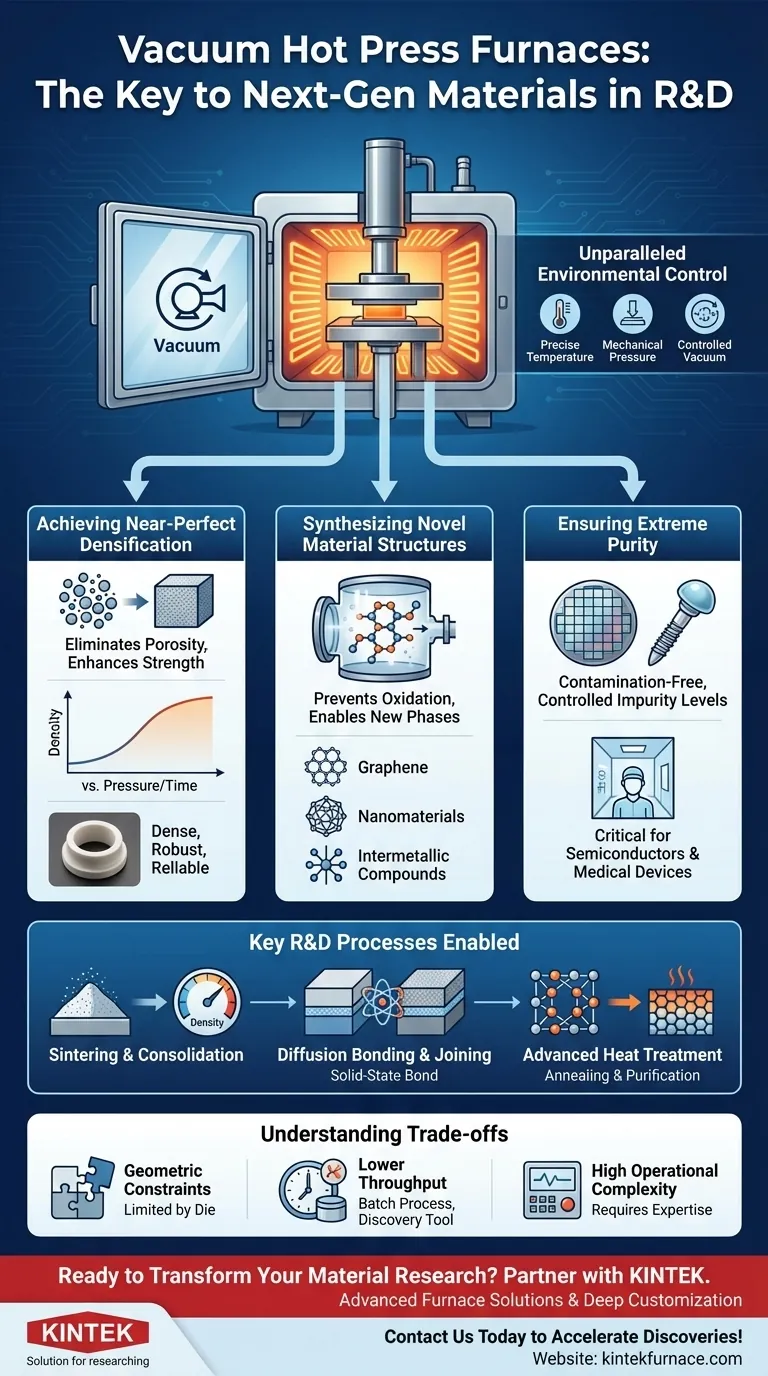

The core value of a vacuum hot press in an R&D setting is not just heating and pressing; it is the unparalleled environmental control it provides. This control over temperature, pressure, and atmosphere is the key to unlocking new material properties and enabling fundamental scientific discovery.

Why Control Is the Cornerstone of Material Innovation

In materials science, the final properties of a material are dictated by its microscopic structure. Vacuum hot press furnaces give researchers direct command over the variables that shape this structure, allowing them to move beyond theoretical models and create physical prototypes.

Achieving Near-Perfect Densification

Most advanced ceramics and powdered metals are formed by consolidating powders into a solid mass. A vacuum hot press excels at this by using pressure to physically force particles together, eliminating porosity that weakens the final material.

This process, known as sintering, results in a dense, robust component with superior mechanical strength and reliability, which is critical for high-performance applications.

Synthesizing Novel Material Structures

The combination of a vacuum environment and high temperature allows for the creation of entirely new material phases and structures. The vacuum prevents unwanted chemical reactions, like oxidation, that would occur in the air.

This is essential for the R&D of sensitive materials like graphene, nanomaterials, and certain intermetallic compounds, where even minor contamination can drastically alter the desired properties.

Ensuring Extreme Purity

For industries like semiconductors and medical devices, material purity is non-negotiable. Vacuum furnaces create a contamination-free environment that is essential for producing materials with precisely controlled impurity levels.

This precision ensures the reliability of highly sensitive electronic components and the biocompatibility of medical implants.

Key R&D Processes Enabled by Vacuum Hot Pressing

A vacuum hot press is not a single-function tool but a versatile platform for a range of advanced material processing techniques.

Sintering and Consolidation

This is the primary application. Researchers use the furnace to determine the optimal temperature, pressure, and time needed to bond powders into a dense solid without melting them, forming the basis for new ceramic and metal matrix composites.

Diffusion Bonding and Joining

The furnace can join dissimilar materials that cannot be welded. By applying heat and pressure, atoms from each material are encouraged to migrate across the boundary, creating a solid-state bond that is often as strong as the parent materials. This is vital for prototyping complex, multi-material components.

Advanced Heat Treatment

Researchers use the furnace for processes like annealing and purification. Annealing modifies a material's microstructure to improve ductility or reduce internal stresses, while high-temperature vacuum processing can be used to purify materials by "boiling off" volatile impurities.

Understanding the Trade-offs and Limitations

While powerful, vacuum hot press technology is not a universal solution. Understanding its limitations is key to using it effectively.

Geometric Constraints

The shape and size of the final part are limited by the die used within the press. This makes it ideal for producing simple geometries like pucks, discs, and blocks for material testing, but less suitable for creating complex, near-net-shape components in a single step.

Lower Throughput and Cycle Times

Vacuum hot pressing is a batch process. The time required to load the sample, pump down to a deep vacuum, run the heating and pressing cycle, and cool down can be significant. It is therefore a tool for discovery and prototyping, not mass production.

High Operational Complexity

These furnaces are sophisticated pieces of equipment that require significant operator expertise. Managing the interplay between high temperatures, high pressures, and deep vacuum systems demands careful training to ensure both successful experiments and operational safety.

Making the Right Choice for Your Research Goal

A vacuum hot press is a strategic asset. How you leverage it depends entirely on your R&D objective.

- If your primary focus is novel material discovery: Use the furnace as your core synthesis tool to explore new compositions and phases of advanced ceramics, alloys, and composites.

- If your primary focus is property optimization: Employ the furnace to run systematic studies on sintering and annealing to enhance the density, strength, and performance of existing materials.

- If your primary focus is advanced joining: Leverage diffusion bonding capabilities to prototype and test new methods for joining dissimilar or non-weldable materials for complex assemblies.

Ultimately, the vacuum hot press furnace serves as a gateway, transforming theoretical material concepts into tangible reality.

Summary Table:

| Key Aspect | Role in R&D |

|---|---|

| Environmental Control | Provides precise temperature, pressure, and vacuum for contamination-free synthesis. |

| Densification | Achieves near-perfect density in materials like ceramics and alloys, enhancing strength. |

| Novel Synthesis | Enables creation of new material phases, e.g., graphene and nanomaterials, without oxidation. |

| Purity Assurance | Ensures high purity for sensitive applications in semiconductors and medical devices. |

| Process Versatility | Supports sintering, diffusion bonding, and heat treatment for diverse material development. |

Ready to transform your material research with precision and innovation? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your lab. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Whether you're developing advanced ceramics, alloys, or composites, our vacuum hot press furnaces can help you achieve unparalleled control and purity. Contact us today to discuss how we can enhance your R&D outcomes and accelerate your discoveries!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification