In the medical field, Vacuum Hot Press technology is instrumental for manufacturing high-performance components that demand exceptional purity, density, and strength. Its primary applications include creating high-density ceramic dental implants, sintering advanced titanium alloys for orthopedic prosthetics, and fabricating highly durable surgical tools from specialized metals.

The core value of this technology isn't just forming a shape; it's about creating materials with superior integrity in a controlled environment. For medical devices intended for use inside the human body, the combination of vacuum, heat, and pressure is non-negotiable for ensuring biocompatibility and long-term structural reliability.

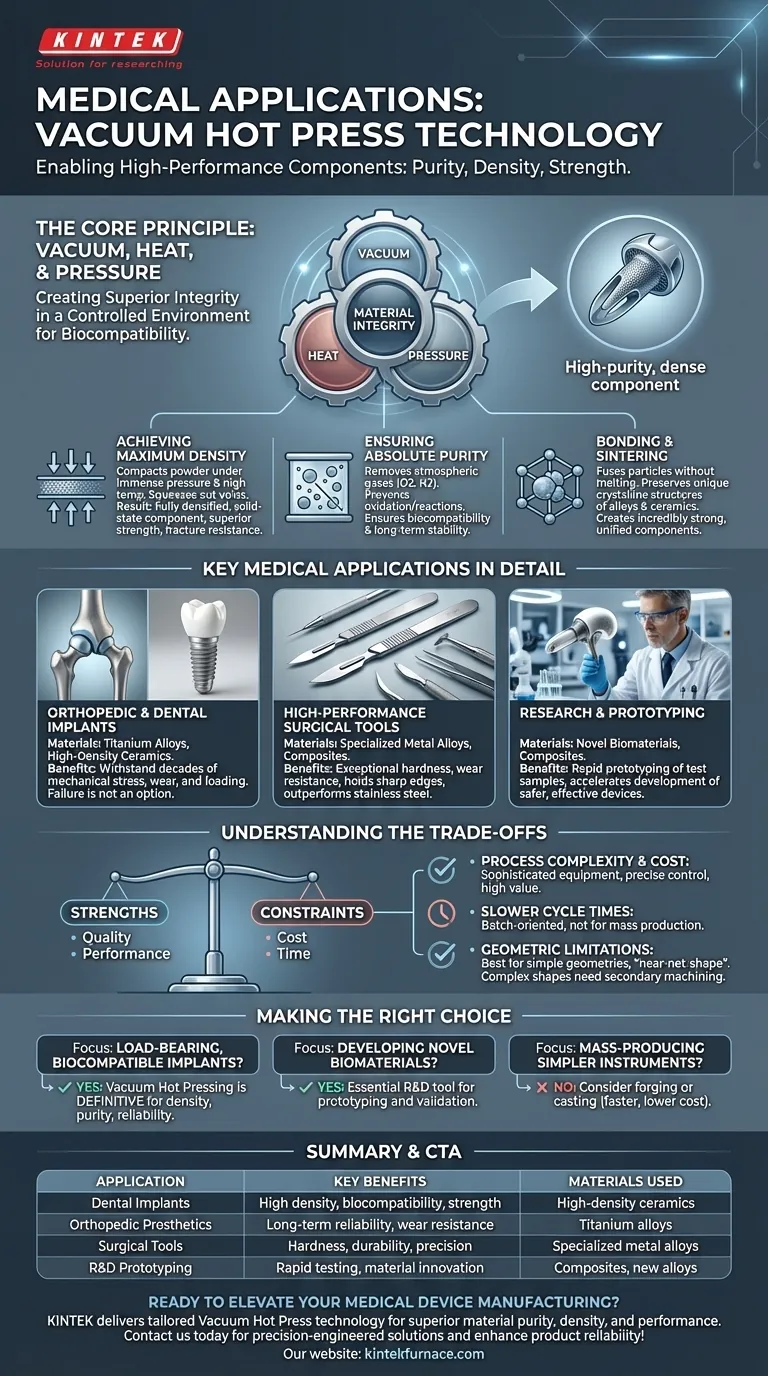

The Core Principle: Why Vacuum, Heat, and Pressure Matter

The unique capabilities of a Vacuum Hot Press stem from its ability to precisely control the manufacturing environment. This control directly translates to a material's final properties, which is critical for medical applications.

Achieving Maximum Density

The process compacts powdered materials, such as ceramics or metal alloys, under immense pressure and high temperature. This force effectively squeezes out voids and porosity between the particles. The result is a fully densified, solid-state component with superior mechanical strength and resistance to fracture, essential for load-bearing implants.

Ensuring Absolute Material Purity

The vacuum environment is the key to biocompatibility. By removing atmospheric gases like oxygen and nitrogen, the process prevents unwanted chemical reactions and oxidation during heating. This ensures the final material is free from contaminants that could cause an adverse reaction or degrade within the body.

Bonding and Sintering Advanced Materials

Hot pressing enables sintering, a process where material particles are fused together into a solid mass without melting them completely. This is vital for materials like titanium alloys and technical ceramics, as it preserves their unique crystalline structures and inherent properties while creating an incredibly strong, unified component.

Key Medical Applications in Detail

The principles of density, purity, and strength are directly applied to produce some of the most critical medical devices.

Orthopedic and Dental Implants

For orthopedic prosthetics like hip and knee joints or ceramic dental implants, failure is not an option. Vacuum hot pressing is used to produce these components from titanium alloys and high-density ceramics because the resulting material can withstand decades of mechanical stress and wear without breaking down.

High-Performance Surgical Tools

Surgical tools require exceptional hardness, wear resistance, and the ability to hold a sharp edge. The technology allows for the creation of specialized metal alloys and composites that far exceed the performance of conventional stainless steel, leading to more precise and durable instruments.

Research and Prototyping

In R&D settings, vacuum hot presses are used to create and test the next generation of biomaterials. The process allows material scientists to rapidly prototype test samples of new composites and alloys, accelerating the development of safer and more effective medical devices.

Understanding the Trade-offs

While powerful, Vacuum Hot Press technology is a specialized solution with specific constraints. Understanding these is key to its proper application.

Process Complexity and Cost

This is not a simple or inexpensive manufacturing method. It requires sophisticated equipment, precise control systems, and significant technical expertise, making it best suited for high-value components where performance justifies the investment.

Slower Cycle Times

Compared to mass-production techniques like casting or injection molding, hot pressing is a batch-oriented process with longer cycle times. Its value lies in quality and material properties, not volume.

Geometric Limitations

The technology is ideal for producing components with relatively simple geometries, often referred to as "near-net-shape" parts. Highly complex or intricate shapes may require secondary machining after the pressing process, which adds time and cost.

Making the Right Choice for Your Goal

To determine if this technology fits your needs, consider the ultimate requirement of the component you are producing.

- If your primary focus is creating load-bearing, biocompatible implants: Vacuum hot pressing is the definitive choice for achieving the required density, purity, and long-term reliability.

- If your primary focus is developing novel biomaterials: This technology is an essential R&D tool for prototyping and validating the properties of new material compositions.

- If your primary focus is mass-producing simpler instruments: Consider alternative, higher-volume methods like forging or casting, as hot pressing may be too slow and costly for your needs.

Ultimately, mastering this technology allows you to engineer materials that meet the highest standards of safety and performance for medical use.

Summary Table:

| Application | Key Benefits | Materials Used |

|---|---|---|

| Dental Implants | High density, biocompatibility, strength | High-density ceramics |

| Orthopedic Prosthetics | Long-term reliability, wear resistance | Titanium alloys |

| Surgical Tools | Hardness, durability, precision | Specialized metal alloys |

| R&D Prototyping | Rapid testing, material innovation | Composites, new alloys |

Ready to elevate your medical device manufacturing with precision-engineered solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing biocompatible implants or durable surgical tools, we deliver tailored Vacuum Hot Press technology to ensure superior material purity, density, and performance. Contact us today to discuss how we can support your innovation and enhance your product reliability!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What is a vacuum hot press furnace? Unlock Superior Material Performance