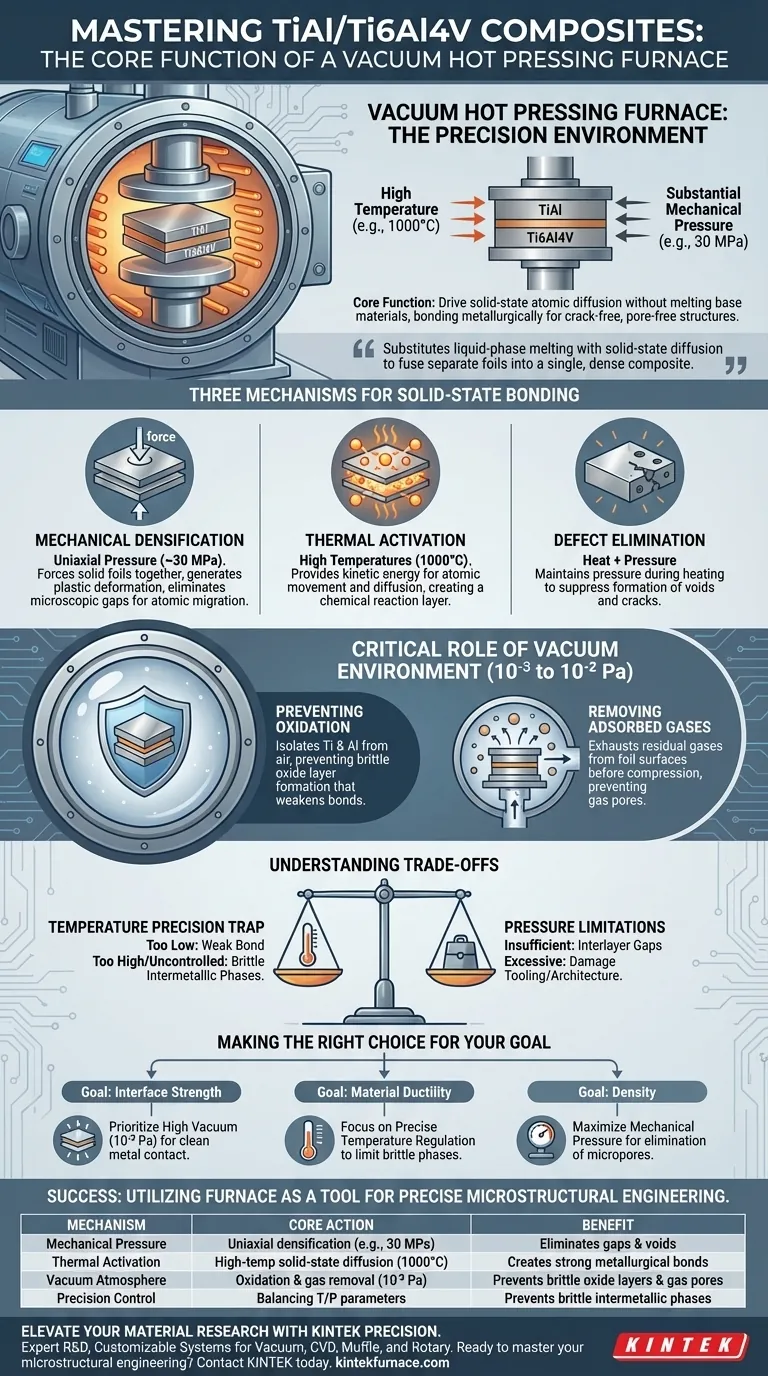

The core function of a vacuum hot pressing furnace is to drive solid-state atomic diffusion between metal layers without melting the base materials. By simultaneously applying high temperature (e.g., 1000°C) and substantial mechanical pressure (e.g., 30 MPa), the equipment forces the Titanium and Aluminum alloy layers to bond metallurgically. This process is essential for creating high-performance layered structures that remain free of cracks and pores.

The furnace acts as a precision environment that substitutes liquid-phase melting with solid-state diffusion. It overcomes the natural barriers of oxidation and surface roughness to fuse separate foils into a single, dense composite material.

Facilitating Solid-State Bonding

The primary challenge in creating TiAl/Ti6Al4V composites is joining distinct layers without compromising their structural integrity. The vacuum hot pressing furnace addresses this through three specific mechanisms.

Mechanical Densification

The application of uniaxial pressure (often around 30 MPa) is critical for physical contact.

It forces the solid metal foils together, generating plastic deformation at the interface.

This pressure eliminates microscopic gaps between layers, ensuring the tight contact required for atoms to migrate between materials.

Thermal Activation

High temperatures, such as 1000°C, provide the kinetic energy necessary for atomic movement.

Heat activates the atoms within the Titanium and Aluminum layers, allowing them to diffuse across the interface boundaries.

This diffusion creates a reaction layer that bonds the materials chemically, not just mechanically.

Defect Elimination

The combination of heat and pressure prevents the formation of common defects.

By maintaining pressure during the heating cycle, the furnace suppresses the formation of voids and cracks that typically occur during material shrinkage or expansion.

The Critical Role of the Vacuum Environment

Beyond heat and pressure, the "vacuum" aspect of the furnace is the enabling factor for processing reactive metals like Titanium and Aluminum.

Preventing Oxidation

Titanium and Aluminum are highly reactive and will oxidize instantly in the presence of air at high temperatures.

The high vacuum environment (e.g., $10^{-3}$ to $10^{-2}$ Pa) isolates the metals from oxygen.

This prevents the formation of brittle oxide layers (scales) on the surface, which would otherwise act as a barrier to diffusion and weaken the final bond.

Removing Adsorbed Gases

Metal foils often have residual gases adsorbed on their surfaces.

The vacuum environment exhausts these gases before the layers are fully compressed.

This effectively prevents the formation of gas pores within the composite, ensuring the final material achieves high density and structural soundness.

Understanding the Trade-offs

While vacuum hot pressing is effective, it requires a delicate balance of operational parameters. It is not simply a matter of "higher is better."

The Temperature Precision Trap

Precise temperature control is the most critical variable in the process.

If the temperature is too low, diffusion will be insufficient, resulting in a weak mechanical bond.

However, if the temperature is too high or uncontrolled, it can lead to the formation of brittle intermetallic phases (such as excessive $Al_3Ti$). These phases destroy the plasticity of the composite and lead to cracking.

Pressure Limitations

Pressure must be high enough to deform the surface asperities (roughness) but controlled enough to avoid distorting the macroscopic shape of the component.

Insufficient pressure leaves interlayer gaps, while excessive pressure can damage the tooling or the composite architecture itself.

Making the Right Choice for Your Goal

When configuring a vacuum hot pressing cycle for TiAl/Ti6Al4V composites, your specific objectives should dictate your parameter settings.

- If your primary focus is Interface Strength: Prioritize establishing a high vacuum ($10^{-3}$ Pa) to ensure the complete removal of oxide film barriers, allowing for direct, virgin metal-to-metal contact.

- If your primary focus is Material Ductility: Focus on precise temperature regulation to facilitate bonding while strictly limiting the growth of brittle intermetallic compound phases.

- If your primary focus is Density: Maximize the application of mechanical pressure during the hold time to ensure the total elimination of micropores and voids.

Success in this process relies on utilizing the furnace not just as a heater, but as a tool for precise microstructural engineering.

Summary Table:

| Mechanism | Core Action | Benefit to Composite |

|---|---|---|

| Mechanical Pressure | Uniaxial densification (e.g., 30 MPa) | Eliminates microscopic gaps and voids |

| Thermal Activation | High-temp solid-state diffusion (1000°C) | Creates strong metallurgical chemical bonds |

| Vacuum Atmosphere | Oxidation & gas removal (10⁻³ Pa) | Prevents brittle oxide layers and gas pores |

| Precision Control | Balancing T/P parameters | Prevents formation of brittle intermetallic phases |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect bond in TiAl/Ti6Al4V layered composites requires more than just heat—it requires total environmental control. KINTEK provides industry-leading Vacuum, CVD, Muffle, and Rotary systems designed for the rigors of high-performance metallurgy.

Backed by expert R&D and precision manufacturing, our lab high-temperature furnaces are fully customizable to meet your specific pressure and vacuum requirements. Whether you are aiming for maximum interface strength or superior material ductility, our engineers are ready to help you optimize your results.

Ready to master your microstructural engineering? Contact KINTEK today for a custom furnace solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the role of a high-strength graphite die in the vacuum hot press sintering of SiC ceramics? Essential Functions

- What functions do graphite molds serve in the vacuum hot pressing of copper-carbon nanotube composites?

- Why is a hot pressing furnace equipped with a vacuum system necessary for sintering high-entropy alloy coatings? Ensure Purity, Density, and Superior Performance

- What core role does a vacuum hot press furnace play in the densification process of copper-carbon nanotube composites? Achieve High-Performance Cu-CNT Materials

- What are the key components of a vacuum press system? Essential Parts for Uniform Pressure and Precision

- How does multi-station continuous vacuum hot pressing sintering equipment affect the production efficiency of diamond products? Boost Yields with Pipeline Sintering

- What are the advantages of using a vacuum hot press sintering furnace for preparing high-density carbon nanotube reinforced copper matrix composites? Achieve Maximum Density and Purity for Superior Performance

- Why is adjustable temperature important in a vacuum hot press furnace? Unlock Precision for Superior Materials Processing