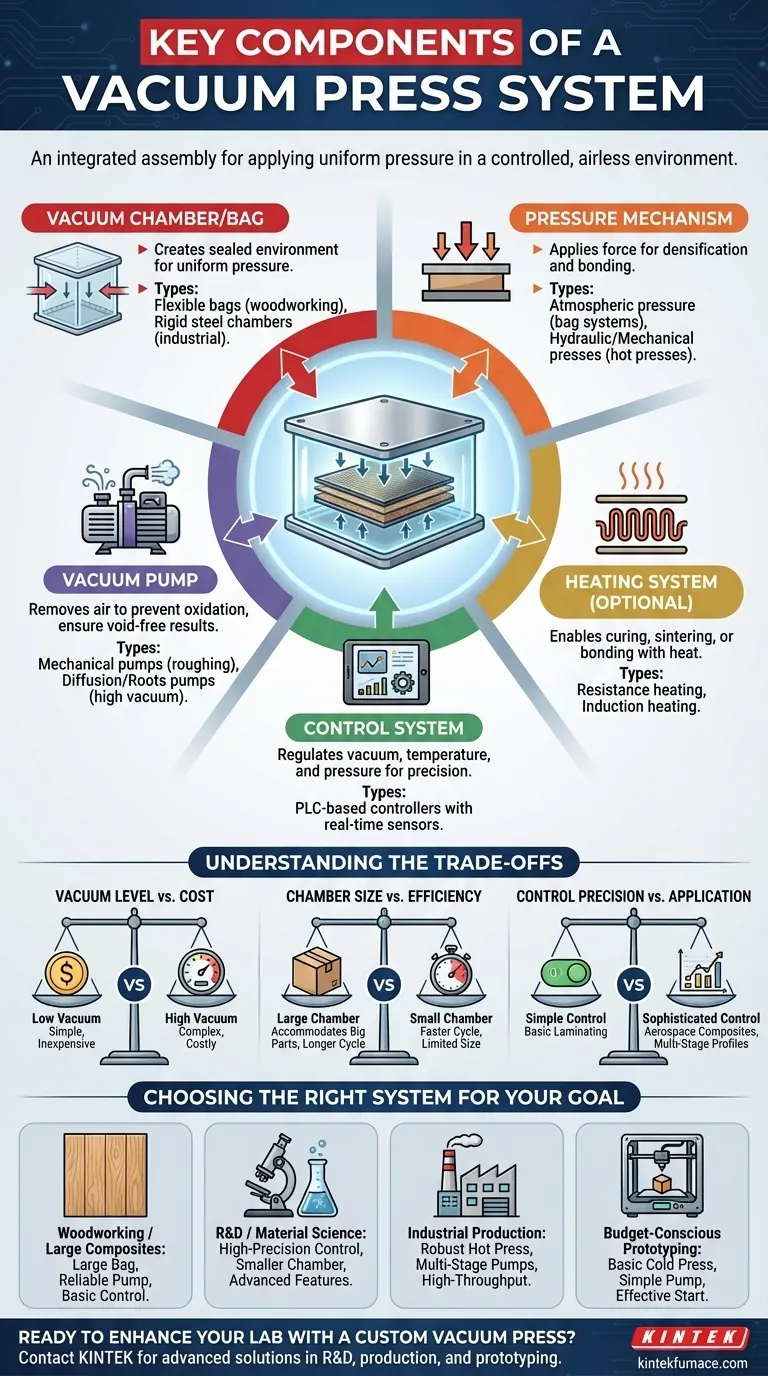

At its core, a vacuum press system is an integrated assembly designed to apply uniform pressure to materials within a controlled, airless environment. The key components that work in concert to achieve this are a vacuum chamber or bag, a vacuum generator (pump), a pressure mechanism, a heating system for hot pressing applications, and a control system to regulate the entire process.

A vacuum press is not simply a collection of parts, but a controlled environment designed to achieve a single goal: applying uniform pressure in a vacuum. Understanding how each component contributes to creating and maintaining this environment is the key to achieving predictable, high-quality results.

The Core Environment: Chamber and Pressure

The primary function of a vacuum press is to create a sealed space where pressure can be applied evenly across a workpiece. This is accomplished by the chamber and the pressure mechanism itself.

The Vacuum Chamber or Bag

This component is the sealed enclosure where the work takes place. Its form depends entirely on the application.

For woodworking or large composite layups, a flexible vinyl or polyurethane bag is used. The workpiece is placed inside, and the bag is sealed around the edges.

For industrial processes like sintering or diffusion bonding, a rigid, heavy-duty steel vacuum chamber is required to withstand high temperatures and pressures.

The Pressure Mechanism

In many systems, particularly those using a vacuum bag, the "press" is simply atmospheric pressure. By removing the air from inside the bag, the ~14.7 psi of the atmosphere exerts a powerful and perfectly uniform clamping force on the workpiece.

For hot presses used in materials science and industrial production, an integrated hydraulic or mechanical press applies additional, controlled force for densification and bonding.

Creating the Vacuum: The Pumping System

The vacuum generator is the heart of the system, responsible for removing air and other gasses from the sealed chamber or bag.

The Role of the Vacuum Generator

The primary job of the vacuum pump is to evacuate the chamber, preventing oxidation and removing trapped air or volatiles from the material. This ensures that laminations are void-free and that reactive materials are not contaminated during heating.

Types of Vacuum Pumps

The type of pump determines the ultimate vacuum level that can be achieved.

Systems are often staged. A mechanical pump (or "roughing pump") removes the bulk of the air. For higher vacuum requirements, a diffusion pump or Roots pump then takes over to achieve much lower pressures, down to levels like 7×10-3 Pa for advanced applications.

The Thermal Component: Heating Systems

For applications that require curing, bonding, or sintering, a heating system is integrated directly into the press. This is the defining feature of a "vacuum hot press."

Why Heat Is Used

Heat acts as a catalyst. It's used to cure resins in composites, sinter powdered metals or ceramics into a solid mass, or facilitate diffusion bonding between two dissimilar materials.

Common Heating Methods

The two most common methods are resistance heating, where electrical current passes through heating elements surrounding the workpiece, and induction heating, which uses electromagnetic fields to heat a conductive susceptor or the material itself.

Precision and Regulation: The Control System

The control system is the brain of the operation, ensuring the entire process is repeatable and precise.

What It Manages

This system monitors and adjusts all critical parameters in real time. Using a network of sensors and a central controller (often a PLC), it manages the vacuum level, the rate of heating and cooling, and the applied pressure.

Ensuring Process Integrity

For advanced materials, the process is not static. The control system is programmed to follow a specific profile, ramping temperature and pressure up and down in precise stages to achieve the desired material properties.

Understanding the Trade-offs

Choosing or designing a vacuum press system involves balancing capability, complexity, and cost.

Vacuum Level vs. Cost

Achieving a basic vacuum for clamping is relatively simple and inexpensive. Reaching a high vacuum for metallurgical processes requires multi-stage pumping systems that are significantly more complex and costly to purchase and maintain.

Chamber Size vs. Efficiency

A larger chamber can accommodate bigger parts, but it also requires a more powerful pump and takes longer to evacuate. This increases both the initial investment and the cycle time for each operation.

Control Precision vs. Application

A simple on/off switch for a pump may be sufficient for laminating a wood veneer. However, producing aerospace-grade composites requires a sophisticated, programmable control system that can execute precise, multi-stage thermal and pressure profiles.

Choosing the Right System for Your Goal

Your final configuration depends entirely on your end goal. Focus on the capabilities that matter most for your specific application.

- If your primary focus is woodworking or large-scale composites: A large vacuum bag system with a reliable mechanical pump is your priority; precise temperature control is often secondary.

- If your primary focus is R&D or material science: Prioritize a system with high-precision control over temperature, pressure, and vacuum levels, even if the chamber size is smaller.

- If your primary focus is industrial production of metals or ceramics: Your system will require a robust hot press design with advanced heating and high-vacuum capabilities from multi-stage pumps.

- If your primary focus is budget-conscious prototyping: A basic cold press setup using a vacuum bag and a simple venturi or diaphragm pump can be a highly effective starting point.

By aligning the capabilities of each component with your specific material and process requirements, you can ensure your vacuum press is a powerful tool for innovation and production.

Summary Table:

| Component | Key Function | Common Types |

|---|---|---|

| Vacuum Chamber/Bag | Creates sealed environment for uniform pressure | Flexible bags, Rigid steel chambers |

| Vacuum Pump | Removes air to prevent oxidation and ensure void-free results | Mechanical pumps, Diffusion pumps |

| Pressure Mechanism | Applies force for densification and bonding | Atmospheric pressure, Hydraulic/mechanical presses |

| Heating System | Enables curing, sintering, or bonding with heat | Resistance heating, Induction heating |

| Control System | Regulates vacuum, temperature, and pressure for precision | PLC-based controllers with sensors |

Ready to enhance your lab's capabilities with a custom vacuum press system? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization to meet unique experimental requirements. Whether you're in R&D, industrial production, or prototyping, we can help you achieve precise, high-quality results. Contact us today to discuss how we can support your innovation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance