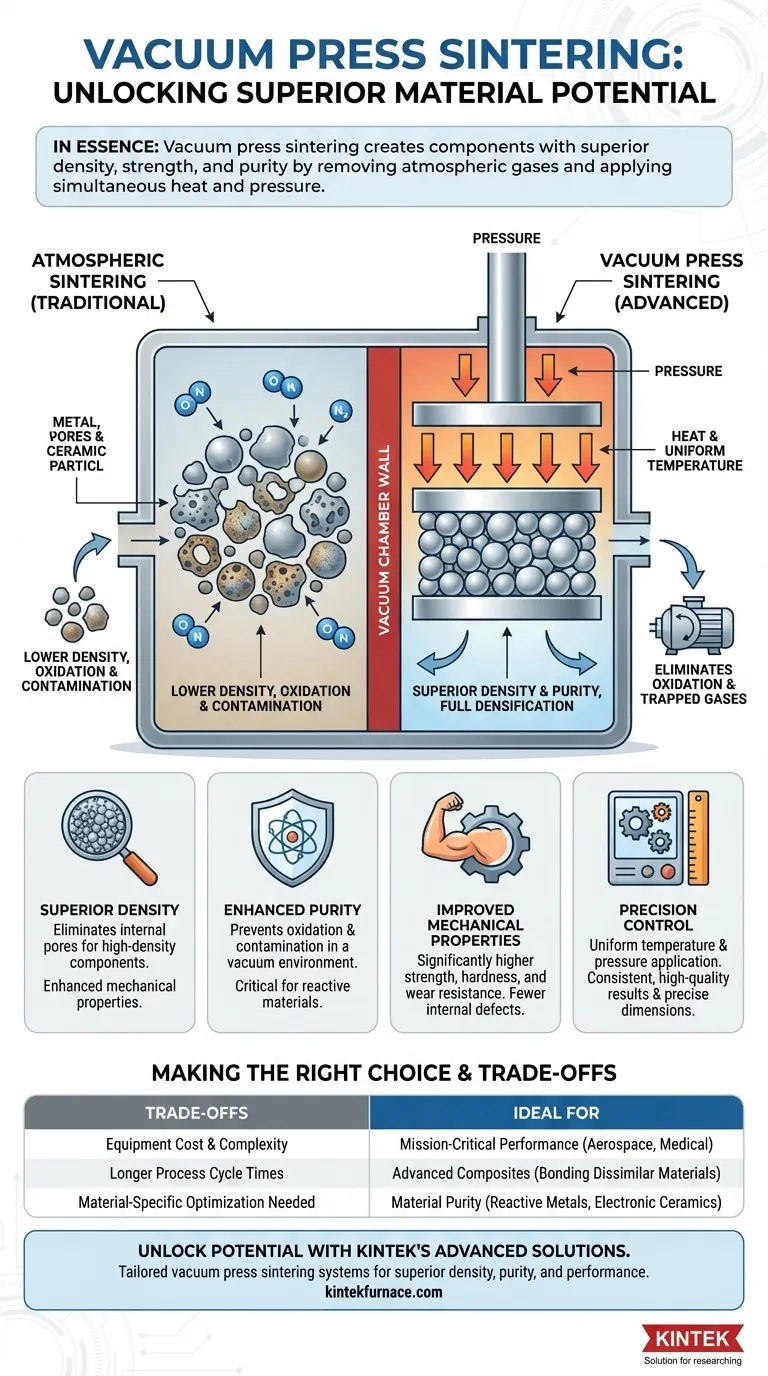

In essence, using a vacuum press for sintering creates components with superior density, strength, and purity. By removing atmospheric gases, the process prevents oxidation and contamination while simultaneously applying heat and pressure, which eliminates internal pores and enhances the material's final mechanical properties and dimensional accuracy.

The decision to use vacuum press sintering is not just about manufacturing a part; it's about engineering a material to its maximum potential. It creates an ideal environment where particles can bond perfectly, free from the impurities and structural flaws that compromise performance in less controlled processes.

Why a Vacuum Environment is Transformative

The core benefits of this technology stem directly from creating a tightly controlled environment free from atmospheric interference. This fundamentally changes how material particles bond together.

Eliminating Oxidation and Contamination

Atmospheric air contains oxygen, nitrogen, and water vapor, all of which can react with metal and ceramic powders at high temperatures. These reactions create unwanted oxides and nitrides that contaminate the material.

A vacuum environment removes these reactive gases. This preserves the purity of the material, which is critical for reactive metals and advanced ceramics used in high-performance applications.

Promoting Full Densification

During sintering, trapped gases can create tiny voids or pores within the final component. These pores are structural weak points that reduce the overall density and strength of the material.

The vacuum actively helps pull these trapped gases out of the powder mass as it compacts. This facilitates superior atomic diffusion, allowing material particles to bond more intimately and form a solid, high-density structure with minimal porosity.

Achieving Superior Mechanical Properties

The direct results of high purity and high density are dramatic improvements in performance. With fewer internal defects and no brittle oxide layers, components exhibit significantly higher strength, hardness, and wear resistance. This is why the process is essential for parts that must endure extreme stress or friction.

The Advantage of Precision Control

Modern vacuum hot presses are highly sophisticated systems that offer unparalleled control over every variable in the sintering process. This precision is key to producing consistent, high-quality results.

Uniform Temperature Distribution

These systems use optimized heating elements and high-quality insulation (like graphite layers) to ensure the temperature is uniform throughout the entire component. This prevents hot spots or cool spots, which could otherwise lead to inconsistent density and internal stresses, creating weak points in the final part.

Precise Pressure Application

The simultaneous application of high pressure alongside heat accelerates the densification process. This combination allows for sintering to occur at lower temperatures or in shorter times than pressureless methods, which can help prevent unwanted grain growth and preserve a fine-grained microstructure, further enhancing strength.

Superior Surface Finish and Dimensional Accuracy

Because the process is so controlled and results in a fully dense part, the final component emerges with a high-quality surface finish and extremely precise dimensions. This significantly reduces or even eliminates the need for costly and time-consuming secondary machining operations.

Understanding the Trade-offs

While the benefits are substantial, a vacuum press is a specialized tool, not a universal solution. Understanding its limitations is key to making an informed decision.

Equipment Cost and Complexity

Vacuum hot presses are complex, highly automated machines. The initial investment is significant, and they require specialized knowledge for operation and maintenance. Features like water-cooled chambers, advanced safety interlocks, and precise controls contribute to this cost.

Process Cycle Times

Achieving a deep vacuum, heating, pressing, and then safely cooling the component under controlled conditions takes time. For many materials, the cycle time in a vacuum press will be longer than for conventional atmospheric sintering, impacting overall throughput.

Material-Specific Optimization

The process is not "plug-and-play." Each material—whether a metal alloy, a ceramic, or a composite—requires a unique set of optimized parameters for temperature, pressure, and vacuum level. Developing this process recipe requires significant expertise and testing.

Making the Right Choice for Your Application

Your choice should be driven by the non-negotiable performance requirements of your final component.

- If your primary focus is maximum performance and reliability: Vacuum sintering is the superior choice for mission-critical aerospace, medical, or defense components where failure is not an option.

- If your primary focus is creating advanced composites: This process is ideal for bonding dissimilar materials, like metals and ceramics, to create parts with unique combinations of hardness and toughness.

- If your primary focus is material purity: For reactive metals or sensitive electronic ceramics, the vacuum environment is non-negotiable to prevent performance-degrading contamination.

- If your primary focus is high-volume, lower-cost production: For components where good-enough performance is acceptable, conventional atmospheric sintering may be a more cost-effective approach.

Ultimately, investing in vacuum press sintering is a strategic decision to prioritize material integrity over production speed or initial cost.

Summary Table:

| Benefit | Description |

|---|---|

| Superior Density | Eliminates pores for high-density components with improved mechanical properties. |

| Enhanced Purity | Prevents oxidation and contamination in a vacuum environment. |

| Precise Control | Uniform temperature and pressure application for consistent results. |

| Improved Mechanical Properties | Higher strength, hardness, and wear resistance in final parts. |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored vacuum press sintering systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior density, purity, and performance for metal and ceramic powders. Contact us today to discuss how our solutions can elevate your sintering processes and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%