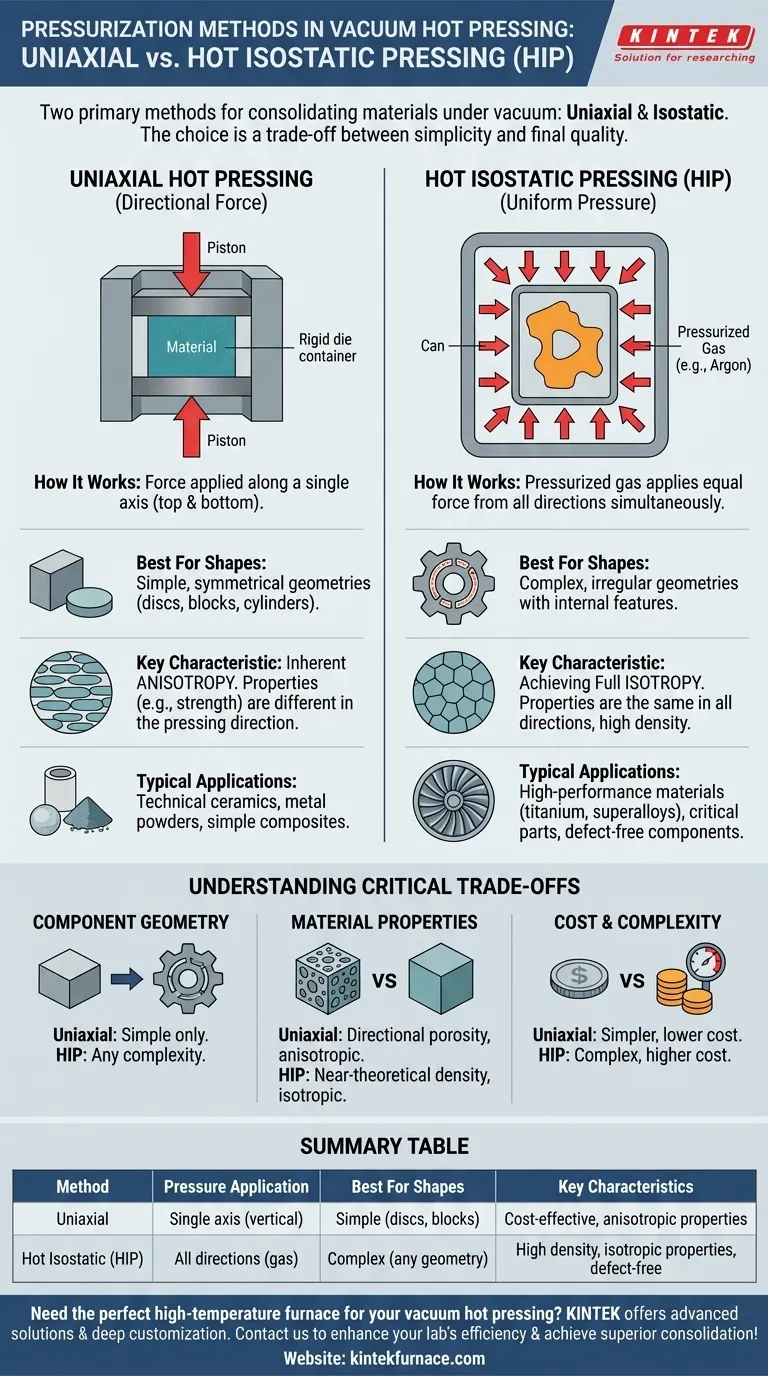

In vacuum hot pressing, there are two primary methods for applying pressure to consolidate materials: uniaxial and isostatic. Uniaxial pressing applies force along a single axis, which is ideal for creating simple shapes like discs or blocks. In contrast, hot isostatic pressing (HIP) uses a pressurized gas to apply equal force from all directions, which is essential for densifying complex shapes and achieving perfectly uniform material properties.

The fundamental choice between pressurization methods is a trade-off between process simplicity and final component quality. Your decision hinges on the required geometry of the part and the necessity for uniform, defect-free material properties.

The Fundamentals of Uniaxial Hot Pressing

Uniaxial hot pressing is the most straightforward method of applying pressure and heat simultaneously in a vacuum environment.

How It Works: The Concept of Directional Force

In this process, a powder or pre-formed part is placed inside a rigid die, typically made of graphite. A ram or piston then compresses the material along a single vertical axis while the system is heated.

The pressure is direct and directional, squeezing the material from the top and bottom. This simplicity makes it a widely used and cost-effective technique.

Typical Applications and Materials

This method is best suited for producing simple, symmetrical geometries such as cylinders, discs, and rectangular blocks.

It is commonly used for densifying a wide range of materials, including many technical ceramics (like silicon carbide), metal powders, and composite materials where the final shape is not complex.

Key Characteristic: Inherent Anisotropy

Because the force is applied along only one axis, the resulting material grains may align preferentially. This can lead to anisotropy, where the material's mechanical and physical properties (like strength or thermal conductivity) are different in the pressing direction compared to the perpendicular directions.

The Principles of Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing, or HIP, is a more advanced technique that provides uniform consolidation, eliminating the directional limitations of uniaxial pressing.

How It Works: Uniform Pressure from All Sides

In a HIP system, the component is hermetically sealed in a metal container or "can." The canned part is then placed inside a high-pressure vessel.

The vessel is heated and simultaneously filled with an inert gas, typically argon, to very high pressures. This gas applies uniform, isostatic pressure to the component from every direction at once.

Typical Applications and Materials

HIP is the gold standard for applications demanding the highest possible density and perfectly uniform properties. It is essential for fabricating parts with complex or irregular geometries that cannot be made in a simple die.

This process is critical for high-performance materials like titanium alloys, superalloys for aerospace, and advanced ceramics used in medical implants or cutting tools, where internal defects cannot be tolerated.

Key Characteristic: Achieving Full Isotropy and Density

The all-directional pressure is exceptionally effective at closing internal voids and porosity within a material. This results in components that reach nearly 100% of their theoretical maximum density.

Furthermore, because the pressure is uniform, the final part is fully isotropic, meaning its properties are the same in all directions.

Understanding the Critical Trade-offs

Choosing the right method requires balancing your technical requirements with process constraints.

Component Geometry and Complexity

Uniaxial pressing is limited to simple shapes that can be ejected from a rigid die. HIP can produce parts of almost any complexity, including those with internal channels or concave features, as the pressure conforms perfectly to the component's surface.

Final Material Properties (Density and Uniformity)

While uniaxial pressing produces dense parts, it may leave residual directional porosity and will likely result in anisotropic properties. HIP is superior for achieving the highest possible density and guaranteeing isotropic, uniform properties throughout the component.

Equipment Cost and Process Complexity

Uniaxial hot presses are generally simpler, smaller, and less expensive to acquire and operate. HIP systems are highly complex, require specialized infrastructure for handling high-pressure gas, and involve a more intensive process (e.g., canning and de-canning the part), making them significantly more costly.

Making the Right Choice for Your Goal

Your selection should be driven by the end-use requirements of the component you are fabricating.

- If your primary focus is cost-effective production of simple shapes: Uniaxial hot pressing is the most direct and economical solution.

- If your primary focus is achieving maximum density in a complex geometry: Hot Isostatic Pressing (HIP) is the necessary and superior method.

- If your primary focus is eliminating all internal defects for a critical, high-reliability part: You must use HIP to ensure complete consolidation and material integrity.

Ultimately, the right pressurization method is the one that meets the engineering demands of your final product.

Summary Table:

| Method | Pressure Application | Best For Shapes | Key Characteristics |

|---|---|---|---|

| Uniaxial | Single axis (vertical) | Simple (discs, blocks) | Cost-effective, anisotropic properties |

| Hot Isostatic (HIP) | All directions (gas) | Complex (any geometry) | High density, isotropic properties, defect-free |

Need the perfect high-temperature furnace for your vacuum hot pressing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your lab's efficiency and achieve superior material consolidation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy