High-intensity mechanical pressure is the critical differentiator in nano-copper sintering because thermal energy alone cannot eliminate the complex pore structures inherent in the material. While temperature initiates atomic diffusion, continuous mechanical pressure is required to physically force the evolution of pores from connected networks into isolated states, ensuring complete densification.

Core Takeaway Relying solely on temperature-driven diffusion leaves structural voids in nano-copper materials. High-intensity pressure is essential to activate specific dislocation mechanisms that mechanically close these gaps, bridging the divide between partial bonding and a fully dense, high-performance material.

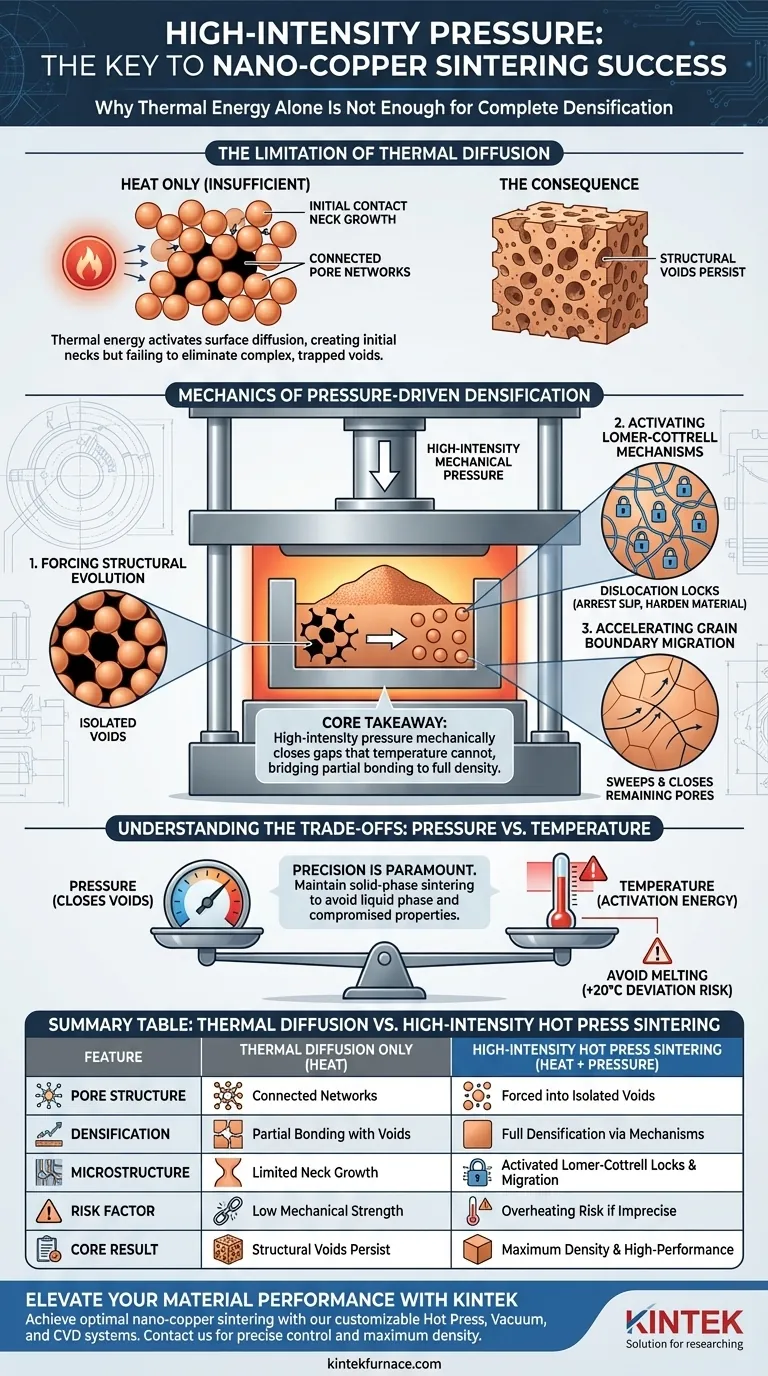

The Limitation of Thermal Diffusion

Why Heat Is Not Enough

In standard sintering, high temperatures provide the activation energy for atomic surface diffusion. However, for nano-copper powder, this mechanism is insufficient to eliminate complex pores trapped between particles.

The Problem of Connected Pores

Without external pressure, pores often remain as connected networks rather than shrinking into oblivion. Thermal diffusion facilitates the initial growth of contact "necks" between particles, but it lacks the physical force required to resolve large, misorientation-type voids.

The Mechanics of Pressure-Driven Densification

Forcing Structural Evolution

Hot press sintering equipment applies continuous mechanical pressure to the powder matrix. This force actively drives the transition of pore structures, converting them from problematic connected states into isolated, manageable voids that can be eliminated.

Activating Lomer-Cottrell Mechanisms

The application of high-intensity pressure induces specific microstructural mechanisms, notably Lomer-Cottrell dislocation locks. These dislocation structures are critical for arresting slip and hardening the material during the densification phase.

Accelerating Grain Boundary Migration

Pressure does not just compress the material; it accelerates grain boundary migration. This movement effectively "sweeps" through the material, facilitating the closure and filling of the remaining large pores that thermal diffusion could not resolve.

Understanding the Trade-offs: Pressure vs. Temperature

The Role of Thermal Precision

While pressure drives the final closing of voids, high-precision temperature control remains the prerequisite foundation. It supplies the activation energy needed to form Shockley partial dislocations and stacking faults, which dominate the initial contact area expansion.

The Risk of Overheating

You cannot simply substitute pressure for temperature accuracy. A deviation of as little as 20°C can push the nano-copper matrix past its melting point.

Avoiding The Liquid Phase

If the material melts and overflows the mold, the density drops sharply, and the mechanical properties are compromised. The goal is strictly solid-phase sintering, where pressure acts on a heated, solid structure—not a liquid one.

Making the Right Choice for Your Goal

To achieve optimal results in nano-copper sintering, you must balance mechanical force with thermal stability.

- If your primary focus is Maximum Density: Prioritize equipment with high-intensity pressure capabilities to actively close misorientation-type pores via Lomer-Cottrell mechanisms.

- If your primary focus is Structural Integrity: Ensure your equipment offers programmable, multi-segment process control to synchronize pressure application with specific stages of dislocation evolution.

- If your primary focus is Process Safety: Verify that the furnace maintains tight thermal precision (avoiding +20°C deviations) to prevent melting while applying the necessary pressure.

True high-performance sintering occurs only when mechanical pressure forces the densification that thermal energy starts.

Summary Table:

| Feature | Thermal Diffusion Only | High-Intensity Hot Press Sintering |

|---|---|---|

| Pore Structure | Remains as connected networks | Forced into isolated, manageable voids |

| Densification | Partial bonding with voids | Full densification via dislocation mechanisms |

| Microstructure | Limited neck growth | Activated Lomer-Cottrell locks & migration |

| Risk Factor | Low mechanical strength | Overheating risk if temperature isn't precise |

| Core Result | Structural voids persist | Maximum density & high-performance material |

Elevate Your Material Performance with KINTEK

Achieve the perfect balance of mechanical force and thermal stability for your nano-copper sintering projects. Backed by expert R&D and manufacturing, KINTEK offers advanced Hot Press, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet your unique densification needs. Whether you require precise Lomer-Cottrell dislocation activation or multi-segment process control, our solutions ensure maximum density without compromising structural integrity. Contact us today to optimize your sintering process!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the basic principle of how a vacuum press works? Harness Atmospheric Pressure for Uniform Clamping

- What is the effect of extended holding time during Vacuum Hot Pressing (VHP)? Enhance Al3Ti Phase Purity and Density

- What physical conditions does a vacuum hot-pressing furnace provide? Optimize GNPs-Cu/Ti6Al4V Composite Preparation

- How does the high-precision temperature control system of a sintering furnace influence nano-copper microstructure?

- What role do vacuum hot press furnaces play in research and development laboratories? Unlock Next-Gen Material Innovations

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What key role does a vacuum hot pressing furnace play in ADSC alloys? Achieve Near-Theoretical Density & Purity

- What is the significance of the rapid heating capability of a hot press furnace? Unlock Nanoscale Sintering Precision