In short, a vacuum press offers significant advantages by creating a controlled, atmosphere-free environment for material processing. This prevents oxidation, ensures perfectly uniform pressure distribution, and enables thermal processes like sintering that produce materials with superior density, strength, and purity compared to conventional methods.

A vacuum press is more than just a tool for applying pressure; it is a system for fundamentally altering a material’s environment. By removing air and other gases, it unlocks processing capabilities and material properties that are simply unattainable at atmospheric pressure.

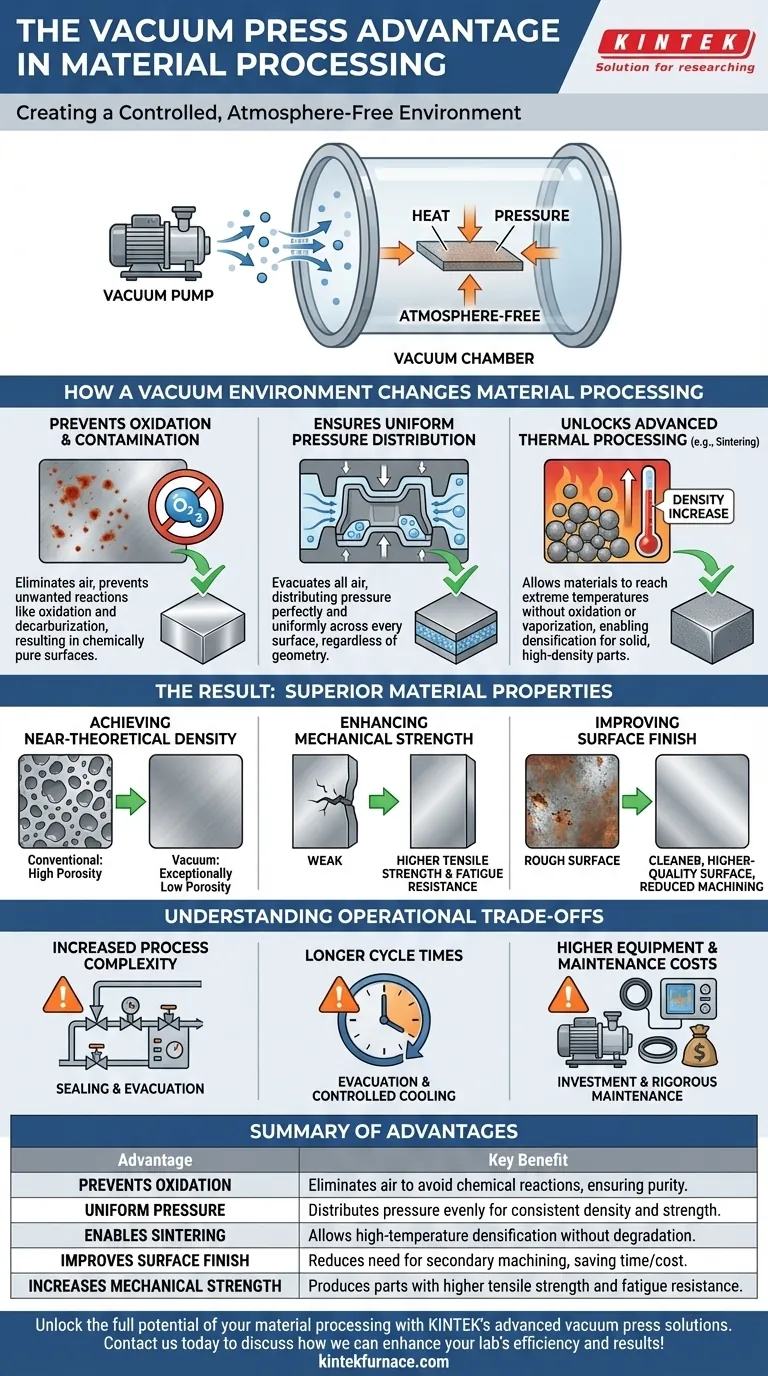

How a Vacuum Environment Changes Material Processing

The core value of a vacuum press comes from removing one variable: the atmosphere. This seemingly simple step has profound effects on how materials respond to heat and pressure.

Prevents Oxidation and Contamination

In a standard press, the air trapped with the material—primarily oxygen and nitrogen—reacts with the workpiece, especially when heated. A vacuum press eliminates this issue.

By removing the air, you prevent unwanted chemical reactions like oxidation (rusting) and decarburization on metals. This results in a chemically pure surface and preserves the material's intrinsic properties.

Ensures Uniform Pressure Distribution

Air pockets trapped between a mold and a complex part can resist compression, creating areas of lower pressure. This leads to inconsistent density and potential weak spots.

A vacuum press evacuates all air, ensuring that the applied mechanical pressure is distributed perfectly and uniformly across every surface of the part, regardless of its geometry.

Unlocks Advanced Thermal Processing

Many advanced processes, like sintering, require high temperatures. In a normal atmosphere, materials can oxidize or even vaporize before they reach the ideal processing temperature.

Under vacuum, the boiling point of materials increases. This allows them to be heated to extreme temperatures where they can soften and densify under pressure without being destroyed, forming a solid, high-density final part.

The Result: Superior Material Properties

The controlled environment directly translates to finished parts with demonstrably better characteristics, making vacuum presses essential for high-performance applications.

Achieving Near-Theoretical Density

Porosity is a critical failure point in many components. The combination of uniform pressure and the elimination of trapped gases allows a vacuum press to create parts with exceptionally low porosity and greater density.

This high density is crucial for applications in aerospace, medical implants, and advanced electronics where internal voids are not an option.

Enhancing Mechanical Strength

A denser, purer material with a more uniform internal structure is inherently stronger.

Parts processed in a vacuum exhibit optimized mechanical properties, including higher tensile strength and greater fatigue resistance, because common points of failure have been engineered out from the start.

Improving Surface Finish

Because oxidation and other surface reactions are prevented, the final part emerges from the press with a cleaner, higher-quality surface. This significantly reduces or eliminates the need for secondary machining or finishing, saving time and cost.

Understanding the Operational Trade-offs

While powerful, this technology is not a universal solution. The advantages come with specific operational considerations that make it a deliberate choice.

Increased Process Complexity

Operating a vacuum press involves more than just applying pressure. The process requires careful sealing of the chamber and a dedicated evacuation phase to remove air, which adds steps and requires skilled operation.

Longer Cycle Times

The evacuation and, often, the controlled cooling phases add significant time to each production cycle. This makes it less suitable for high-volume, low-cost manufacturing where speed is the primary driver.

Higher Equipment and Maintenance Costs

Vacuum pumps, seals, and control systems represent a significant capital investment. These systems also demand rigorous maintenance to ensure the integrity of the vacuum, adding to the overall cost of operation.

Making the Right Choice for Your Application

Choosing to use a vacuum press depends entirely on the required properties of your final component.

- If your primary focus is processing reactive metals or alloys: A vacuum press is essential to prevent oxidation and ensure material purity.

- If your primary focus is creating complex parts with uniform density: The even pressure distribution of a vacuum press is critical for eliminating weak spots.

- If your primary focus is achieving maximum performance and strength: A vacuum press is the definitive tool for producing high-density, low-porosity components for critical applications.

By understanding the fundamental principles of a vacuum press, you can make an informed decision to achieve your specific material goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevents Oxidation | Eliminates air to avoid chemical reactions, ensuring material purity |

| Uniform Pressure | Distributes pressure evenly for consistent density and strength |

| Enables Sintering | Allows high-temperature densification without material degradation |

| Improves Surface Finish | Reduces need for secondary machining, saving time and costs |

| Increases Mechanical Strength | Produces parts with higher tensile strength and fatigue resistance |

Unlock the full potential of your material processing with KINTEK's advanced vacuum press solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior density, purity, and performance. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production