At its core, vacuum hot pressing is a high-performance manufacturing process that uses simultaneous high temperature and mechanical pressure in a vacuum environment. Its purpose is to consolidate powders or bond materials together, creating an final product that is exceptionally dense, pure, and free of internal voids. This method is specifically chosen when conventional sintering or pressing fails to achieve the required material properties.

The true purpose of vacuum hot pressing is not simply to form a part, but to fundamentally engineer a material's microstructure. It overcomes the natural limitations of difficult-to-process materials to achieve near-perfect density and purity, unlocking performance characteristics that are otherwise unattainable.

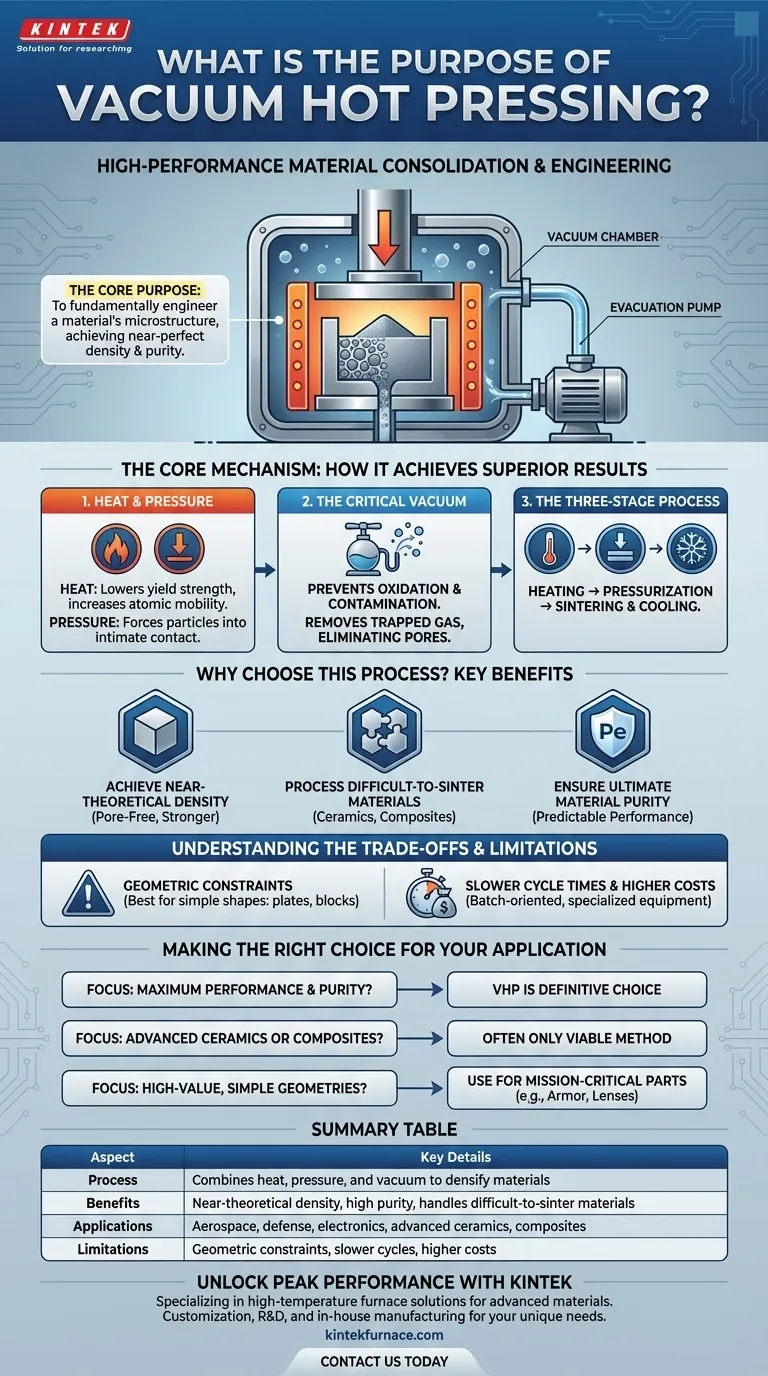

The Core Mechanism: How It Achieves Superior Results

Vacuum hot pressing operates on a simple principle: applying heat softens a material and makes it easier to deform, while pressure forces the material particles together, eliminating the gaps between them. The vacuum environment is the critical third element that makes this process uniquely effective for advanced materials.

Combining Heat and Pressure

Heat provides the thermal energy needed to lower the material's yield strength and increase atomic mobility. Simultaneously, the press applies mechanical energy, which physically forces particles into intimate contact, accelerating the process of densification.

The Critical Role of the Vacuum

Removing air from the chamber serves two vital functions. First, it prevents oxidation and contamination, which is crucial for reactive materials like certain metals, alloys, and non-oxide ceramics. Second, it removes gas that would otherwise become trapped between particles, creating pores that weaken the final part.

The Three-Stage Process

The process is meticulously controlled and consists of three main stages:

- Heating: The material and mold are heated to a specific temperature in the vacuum chamber.

- Pressurization: Once the target temperature is reached, uniaxial pressure is applied and held for a set duration.

- Sintering & Cooling: The combined heat and pressure cause the material particles to bond and densify into a solid mass before a controlled cooling cycle begins.

Why Choose This Process? Key Benefits

Engineers and material scientists turn to vacuum hot pressing when the end-application demands performance levels that standard fabrication methods cannot deliver.

Achieving Near-Theoretical Density

The primary benefit is the ability to create a pore-free structure. Pores are internal defects that can initiate cracks, block thermal paths, and scatter light. By eliminating them, vacuum hot pressing drastically improves a material's mechanical strength, thermal conductivity, and optical clarity.

Processing Difficult-to-Sinter Materials

Many advanced ceramics, composites, and refractory metals have very low diffusion coefficients. This means their atoms do not move and bond easily with heat alone. The addition of high pressure provides the necessary driving force to achieve full densification where conventional sintering would fail.

Ensuring Ultimate Material Purity

For applications in aerospace, defense, or high-performance electronics, even minimal contamination can lead to catastrophic failure. The vacuum environment ensures that the material's intrinsic properties are preserved, resulting in a finished product with predictable and reliable performance.

Understanding the Trade-offs and Limitations

While powerful, vacuum hot pressing is a specialized tool with specific constraints. It is not a one-size-fits-all solution.

Geometric Constraints

The process is best suited for producing simple shapes like plates, blocks, and cylinders. While more complex shapes are possible, they require highly sophisticated and expensive pressing dies made from materials (like graphite) that can withstand extreme temperature and pressure.

Slower Cycle Times

Compared to processes like casting or powder injection molding, vacuum hot pressing is a relatively slow, batch-oriented process. The need to create a vacuum, precisely control heating and cooling rates, and apply pressure over time limits its throughput.

Higher Operational Costs

The equipment—a vacuum chamber, a high-temperature furnace, a hydraulic press, and a sophisticated control system—is expensive to acquire and operate. This cost is justified only when the performance requirements of the final component are non-negotiable.

Making the Right Choice for Your Application

Selecting vacuum hot pressing depends entirely on your end goal and whether the trade-offs are acceptable for your project.

- If your primary focus is maximum performance and purity: This process is the definitive choice for creating components with the highest possible strength, thermal conductivity, or optical transparency.

- If your primary focus is processing advanced ceramics or composites: This is often the only viable method for fully densifying materials that resist conventional sintering techniques.

- If your primary focus is producing high-value, simple geometries: Use this process for mission-critical parts like sputtering targets, armor plates, or specialty lenses where material integrity is far more important than shape complexity or production volume.

Ultimately, vacuum hot pressing is the solution for when you must push a material to the absolute limit of its potential.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Combines heat, pressure, and vacuum to densify materials |

| Benefits | Near-theoretical density, high purity, handles difficult-to-sinter materials |

| Applications | Aerospace, defense, electronics, advanced ceramics, composites |

| Limitations | Geometric constraints, slower cycles, higher costs |

Unlock Peak Performance for Your Materials with KINTEK

Are you working with advanced ceramics, composites, or other hard-to-process materials that demand exceptional density and purity? KINTEK specializes in high-temperature furnace solutions tailored to your unique needs. Leveraging our strong R&D and in-house manufacturing, we offer a diverse product line—including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems—all backed by deep customization capabilities to precisely meet your experimental and production requirements.

Don't let material limitations hold you back. Contact us today to discuss how our vacuum hot pressing and other advanced furnace technologies can help you achieve superior results in aerospace, electronics, and beyond!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy