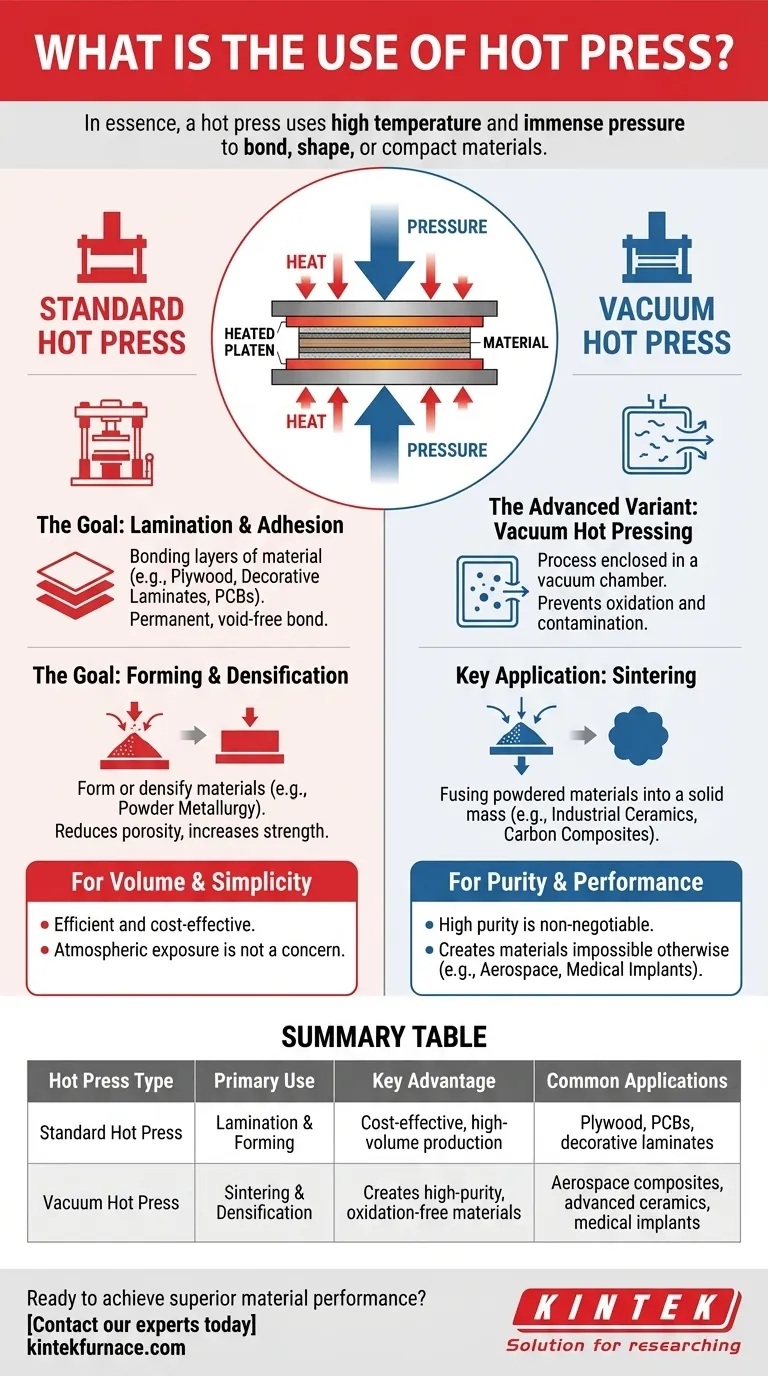

In essence, a hot press is a machine that uses high temperature and immense pressure to bond, shape, or compact materials. It is a fundamental tool for manufacturing composite materials, laminates, and densified powders, with applications ranging from common wood products to advanced aerospace components.

A hot press is not a single tool but a category of equipment defined by its core function: applying heat and pressure. The key distinction lies in its operating environment—a standard press is for lamination and forming, while a vacuum hot press is for creating high-purity, advanced materials free from atmospheric contamination.

The Fundamental Principle: Combining Heat and Pressure

A hot press operates on a straightforward yet powerful principle. Understanding this is key to seeing its versatility across different industries.

How It Works

At its core, a hot press consists of two heated plates, known as platens. Material is placed between these platens, which are then brought together by a hydraulic system to apply a specific, controlled amount of force.

The combination of heat softens the material or activates bonding agents, while the pressure ensures uniform contact, eliminates voids, and forces the material into its final shape or density.

The Goal: Lamination and Adhesion

One of the most common uses is lamination. This involves bonding layers of material together.

Applications include creating plywood from wood veneers, manufacturing decorative laminates for furniture, and producing the copper-clad laminates that form the base of printed circuit boards (PCBs). The heat and pressure ensure a permanent, void-free bond.

The Goal: Forming and Densification

A hot press can also be used to form or densify materials. This is common in powder metallurgy, where metal powders are pressed into a solid, dense part. The process reduces porosity and increases the strength of the final component.

The Advanced Variant: Vacuum Hot Pressing

For many advanced applications, performing this process in open air is not an option. This is where vacuum hot pressing becomes essential.

Why Introduce a Vacuum?

Many advanced materials, like refractory metals or certain ceramics, will oxidize or become contaminated when heated in the presence of air. This compromises their structural integrity and performance.

A vacuum hot press encloses the entire process in a chamber where the atmosphere is removed. This protective environment is critical for achieving high purity and desired material properties.

Key Application: Sintering

Vacuum hot pressing is ideal for sintering. This is a process where powdered materials are fused together into a solid mass using heat and pressure, but without melting them completely.

This technique is used to create industrial ceramics, carbon composites, and other advanced materials with exceptional hardness, heat resistance, and specific electrical properties.

Creating High-Performance Components

The result of vacuum hot pressing is the ability to produce lightweight, high-strength parts for demanding industries.

These include components for aerospace, biocompatible materials for medical implants, and substrates for high-performance electronics.

Understanding the Trade-offs

Choosing the right type of hot press depends entirely on the material and the desired outcome. The primary trade-off is between process simplicity and material purity.

Standard Hot Press: For Volume and Simplicity

A standard, non-vacuum hot press is a workhorse for industries like woodworking and basic electronics manufacturing.

It is highly efficient and cost-effective for bonding materials where atmospheric exposure during the process is not a concern. Its focus is on adhesion and forming, not on preventing chemical reactions like oxidation.

Vacuum Hot Press: For Purity and Performance

A vacuum hot press is a specialized, higher-cost instrument essential for research, development, and advanced manufacturing.

It is chosen when material purity is non-negotiable. The complexity of the vacuum system is a direct trade-off for the ability to produce materials that would otherwise be impossible to create, such as transparent ceramics or oxygen-sensitive metal alloys.

Making the Right Choice for Your Goal

The decision to use a hot press, and which type, is driven by the final properties your material must possess.

- If your primary focus is bonding sheets or laminates: A standard hot press provides the most efficient and cost-effective solution for applications like plywood and decorative surfaces.

- If your primary focus is creating high-purity, high-performance materials: A vacuum hot press is essential for processes like sintering advanced ceramics, composites, and refractory metals where oxidation must be prevented.

- If your primary focus is research and development: A vacuum hot press offers the versatility to experiment with a wide range of sensitive materials and pioneer new composite structures.

Understanding this technology empowers you to select the precise manufacturing process required to achieve your material performance goals.

Summary Table:

| Hot Press Type | Primary Use | Key Advantage | Common Applications |

|---|---|---|---|

| Standard Hot Press | Lamination & Forming | Cost-effective, high-volume production | Plywood, PCBs, decorative laminates |

| Vacuum Hot Press | Sintering & Densification | Creates high-purity, oxidation-free materials | Aerospace composites, advanced ceramics, medical implants |

Ready to achieve superior material performance?

Whether your goal is high-volume lamination or pioneering R&D with sensitive materials, KINTEK's expertise is your solution. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions.

Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Contact our experts today to discuss how our hot press solutions can empower your research and production.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance