In the world of advanced materials processing, a vacuum hot press is a specialized system that simultaneously applies high temperature and high pressure to a material within a controlled vacuum. Its primary function is to bond, densify, or form materials like ceramics, metals, and composites. By operating in a vacuum, it eliminates atmospheric gases like oxygen, preventing contamination and oxidation during the high-temperature process.

The true value of a vacuum hot press lies not just in applying heat and pressure, but in doing so within a pristine vacuum environment. This eliminates atmospheric interference, allowing for the creation of advanced materials with exceptional purity, density, and strength that would be impossible to achieve otherwise.

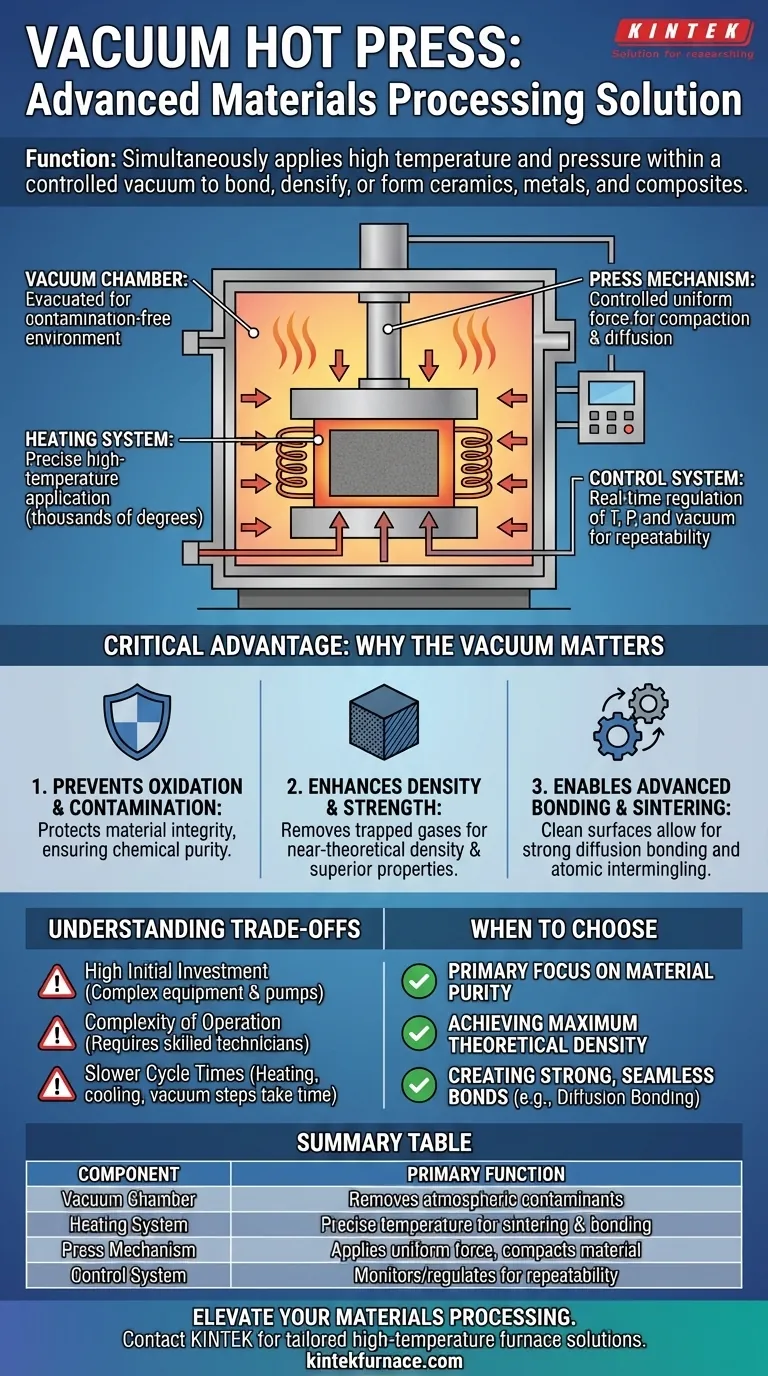

How a Vacuum Hot Press Works: The Core Components

To understand its function, you must first understand its key systems. Each component plays a critical role in achieving the final material properties.

The Vacuum Chamber

The entire process takes place inside a sealed chamber. This robust steel vessel is evacuated by a system of pumps to create a low-pressure, or vacuum, environment. Its sole purpose is to remove atmospheric contaminants that could react with the material at high temperatures.

The Heating System

Inside the chamber, a high-power heating system raises the material's temperature with extreme precision. This is typically done through resistance or induction heating elements that can reach thousands of degrees, enabling processes like sintering and diffusion bonding.

The Press Mechanism

A hydraulic or mechanical press applies a controlled, uniform force onto the material. This pressure compacts the material, eliminates internal voids, and encourages atomic diffusion between particles or layers, leading to a dense and robust final product.

The Control System

This is the brain of the operation. A sophisticated control system monitors and regulates temperature, pressure, and vacuum levels in real-time. This ensures the process is highly repeatable and precise, which is critical for both scientific research and industrial production.

The Critical Advantage: Why the Vacuum Matters

Removing the air from the chamber is what separates a vacuum hot press from a standard furnace or press. This single factor provides three distinct and powerful advantages.

Preventing Oxidation and Contamination

Many advanced materials, especially metals and certain ceramics, will rapidly oxidize or become contaminated when heated in the presence of air. The vacuum environment protects the material's integrity, ensuring its chemical purity and intended properties are preserved.

Enhancing Material Density and Strength

As the material is heated and pressed, any trapped gases can inhibit full densification, leaving microscopic voids that weaken the final part. The vacuum removes these trapped gases, allowing the pressure to create a component with near-theoretical density, significantly improving its mechanical strength and thermal conductivity.

Enabling Advanced Bonding and Sintering

Processes like diffusion bonding, where two separate parts are joined into a single piece at an atomic level, are only possible in a vacuum. The clean, oxide-free surfaces allow atoms to intermingle freely under heat and pressure, creating a bond as strong as the parent material itself. This same principle enhances the sintering of powdered materials.

Understanding the Trade-offs

While powerful, this technology is not a universal solution. Its specialized nature comes with important considerations.

High Initial Investment

Vacuum hot press systems are complex and expensive pieces of equipment. The cost of the vacuum pumps, precision controls, and robust chamber represents a significant capital investment compared to standard atmosphere furnaces.

Complexity of Operation

Proper operation requires a skilled technician who understands vacuum technology, material science, and process control. The setup, programming, and maintenance are more involved than with simpler thermal processing equipment.

Slower Cycle Times

Achieving a deep vacuum and executing a precise heating and cooling profile takes time. As a result, the cycle time per part is often longer than for processes run in an open atmosphere, making it better suited for high-value components rather than mass production.

When to Choose a Vacuum Hot Press

Your decision should be based on the non-negotiable requirements of your final material.

- If your primary focus is material purity: This technology is essential for processing reactive metals, non-oxide ceramics, or any material where preventing even slight oxidation is critical.

- If your primary focus is achieving maximum theoretical density: The combination of pressure and vacuum to remove trapped gases is necessary for creating fully dense, void-free components with superior mechanical properties.

- If your primary focus is creating strong, seamless bonds: For diffusion bonding dissimilar materials or producing high-performance composites, the vacuum hot press provides an unparalleled environment for success.

Ultimately, a vacuum hot press is an enabling tool for innovation, allowing you to create materials and components that simply cannot be made any other way.

Summary Table:

| Component | Primary Function |

|---|---|

| Vacuum Chamber | Removes atmospheric contaminants to prevent oxidation and contamination |

| Heating System | Raises material temperature precisely for sintering and bonding |

| Press Mechanism | Applies uniform force to compact material and eliminate voids |

| Control System | Monitors and regulates temperature, pressure, and vacuum for repeatability |

Ready to elevate your materials processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your lab. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Whether you're working with ceramics, metals, or composites, our vacuum hot press systems ensure contamination-free, high-density results. Contact us today to discuss how we can help you achieve superior material properties and innovation in your research or production!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What is the process of hot pressing? A Guide to Achieving Superior Material Density