At its core, a vacuum hot press furnace is a specialized system designed to create exceptionally dense, high-performance materials. It uniquely combines three critical elements—intense heat, high mechanical pressure, and a vacuum environment—to consolidate powders or bond components into a solid form with superior properties that are often impossible to achieve through conventional heating or pressing alone.

The primary purpose of a vacuum hot press is not just to heat material, but to simultaneously squeeze it in a controlled, oxygen-free environment. This process eliminates internal porosity, prevents contamination, and enables the fabrication of advanced ceramics, composites, and metal components for the most demanding industries.

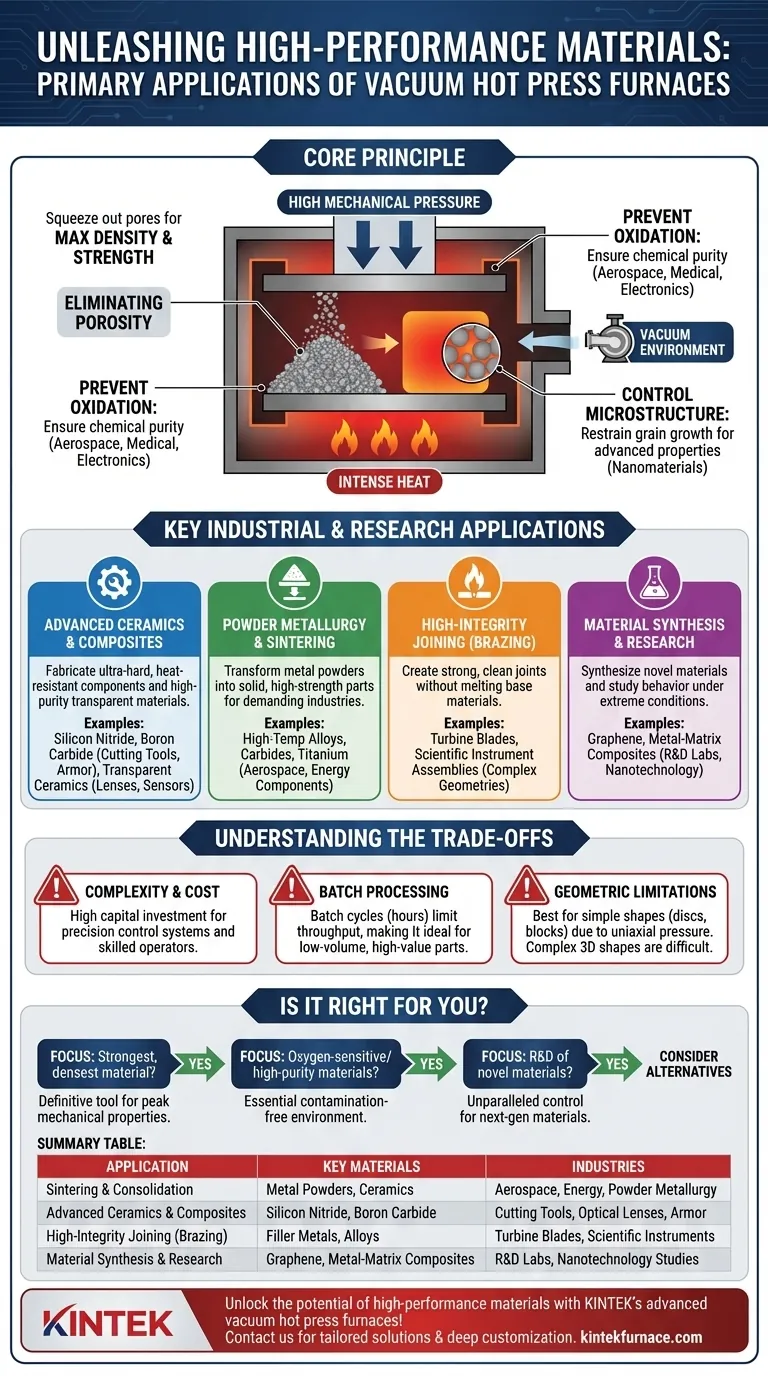

The Core Principle: Why Combine Heat, Pressure, and Vacuum?

Understanding the function of a vacuum hot press requires looking at how each of its three core functions—heat, pressure, and vacuum—work together to manipulate a material at the microscopic level.

Eliminating Porosity for Maximum Density

The defining application is sintering and consolidation. Heat makes the material particles malleable, while the applied mechanical pressure physically forces them together, squeezing out the empty spaces or pores between them.

This results in a final product with near-total density, which is directly linked to improved mechanical strength, hardness, and thermal and electrical conductivity.

Preventing Oxidation and Contamination

Performing this process in a vacuum is critical when working with reactive materials. The vacuum removes oxygen and other atmospheric gases that would otherwise cause unwanted chemical reactions, like oxidation, at high temperatures.

This ensures the chemical purity of the final material, which is essential for applications in aerospace, medical implants, and electronics.

Controlling Microstructure and Grain Growth

For advanced materials, especially nanomaterials, controlling the size of the crystal grains is crucial. The combination of heat and pressure can accelerate the consolidation process at lower temperatures or for shorter times than conventional sintering.

This rapid processing helps restrain the growth of crystal grains, preserving the unique and desirable properties of the nanoscale structure in the final, solid component.

Key Industrial and Research Applications

The unique capabilities of vacuum hot pressing make it indispensable for creating materials that push the boundaries of performance.

Advanced Ceramics and Composites

This is a primary application area. The process is used to fabricate ultra-hard and temperature-resistant components from materials like silicon nitride and boron carbide for cutting tools and wear-resistant parts.

It is also used to produce high-purity transparent ceramics for optical lenses, electronic sensors, and transparent armor.

Powder Metallurgy and Sintering

Vacuum hot pressing is a cornerstone of powder metallurgy. It transforms metal powders—including high-temperature alloys, carbides, and titanium—into solid, high-strength parts.

These components are vital for the aerospace and energy industries, where materials must withstand extreme conditions without failure.

High-Integrity Joining (Brazing)

The furnace can be used for high-reliability vacuum brazing. By heating components and a filler metal in a vacuum, extremely strong and clean joints are created without melting the base materials.

This is essential for joining complex assemblies, such as turbine blades or components for scientific instruments, where joint integrity is non-negotiable.

Material Synthesis and Research

In research and development, these furnaces are invaluable tools for creating and testing novel materials. They are used in the synthesis of graphene, the development of new metal-matrix composites, and the fundamental study of material behavior under extreme conditions.

Understanding the Trade-offs

While powerful, vacuum hot pressing is a specialized process with specific limitations that make it suitable for high-value, not high-volume, applications.

Complexity and Cost

These are complex and expensive systems to purchase, operate, and maintain. The precision controls for vacuum, temperature, and pressure require significant capital investment and skilled operators.

Batch Processing and Cycle Times

Vacuum hot pressing is a batch process, not a continuous one. Each cycle of loading, pumping down the vacuum, heating, pressing, and cooling can take several hours, limiting throughput.

This makes it unsuitable for mass production but ideal for low-volume, high-performance components where quality is more important than quantity.

Geometric Limitations

The process is best suited for relatively simple geometries, such as discs, blocks, or cylinders, due to the nature of applying uniaxial (single-direction) pressure. Complex, three-dimensional shapes are difficult to produce directly.

Is a Vacuum Hot Press Right for Your Application?

Choosing this technology depends entirely on your material and performance goals.

- If your primary focus is producing the strongest, densest material possible: A vacuum hot press is the definitive tool for eliminating porosity and achieving peak mechanical properties in ceramics and powdered metals.

- If your primary focus is working with oxygen-sensitive or high-purity materials: The integrated vacuum system provides an essential, contamination-free environment that other furnace types cannot match.

- If your primary focus is research and development of novel materials: This technology offers unparalleled control over processing parameters, making it an indispensable instrument for creating the next generation of composites and nanostructured materials.

Ultimately, a vacuum hot press is the technology of choice when the absolute performance and purity of a material are the most critical engineering requirements.

Summary Table:

| Application | Key Materials | Industries/Fields |

|---|---|---|

| Sintering & Consolidation | Metal powders, ceramics | Aerospace, energy, powder metallurgy |

| Advanced Ceramics & Composites | Silicon nitride, boron carbide | Cutting tools, optical lenses, armor |

| High-Integrity Joining (Brazing) | Filler metals, alloys | Turbine blades, scientific instruments |

| Material Synthesis & Research | Graphene, metal-matrix composites | R&D labs, nanotechnology studies |

Unlock the potential of high-performance materials with KINTEK's advanced vacuum hot press furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether you're developing advanced ceramics, composites, or conducting cutting-edge research. Contact us today to discuss how our expertise can enhance your material processing and drive innovation in your projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results