A vacuum press is essential for fabricating a range of high-performance materials that cannot be created using conventional atmospheric methods. The primary categories include ceramic/metal composites (cermets), intermetallic compounds, and advanced technical ceramics. These materials are defined by their exceptional density, purity, and tailored properties.

The true value of a vacuum press lies in the controlled environment it creates. By combining high temperature and pressure in an oxygen-free vacuum, the process eliminates porosity and prevents unwanted chemical reactions, resulting in materials with superior density, strength, and thermal stability.

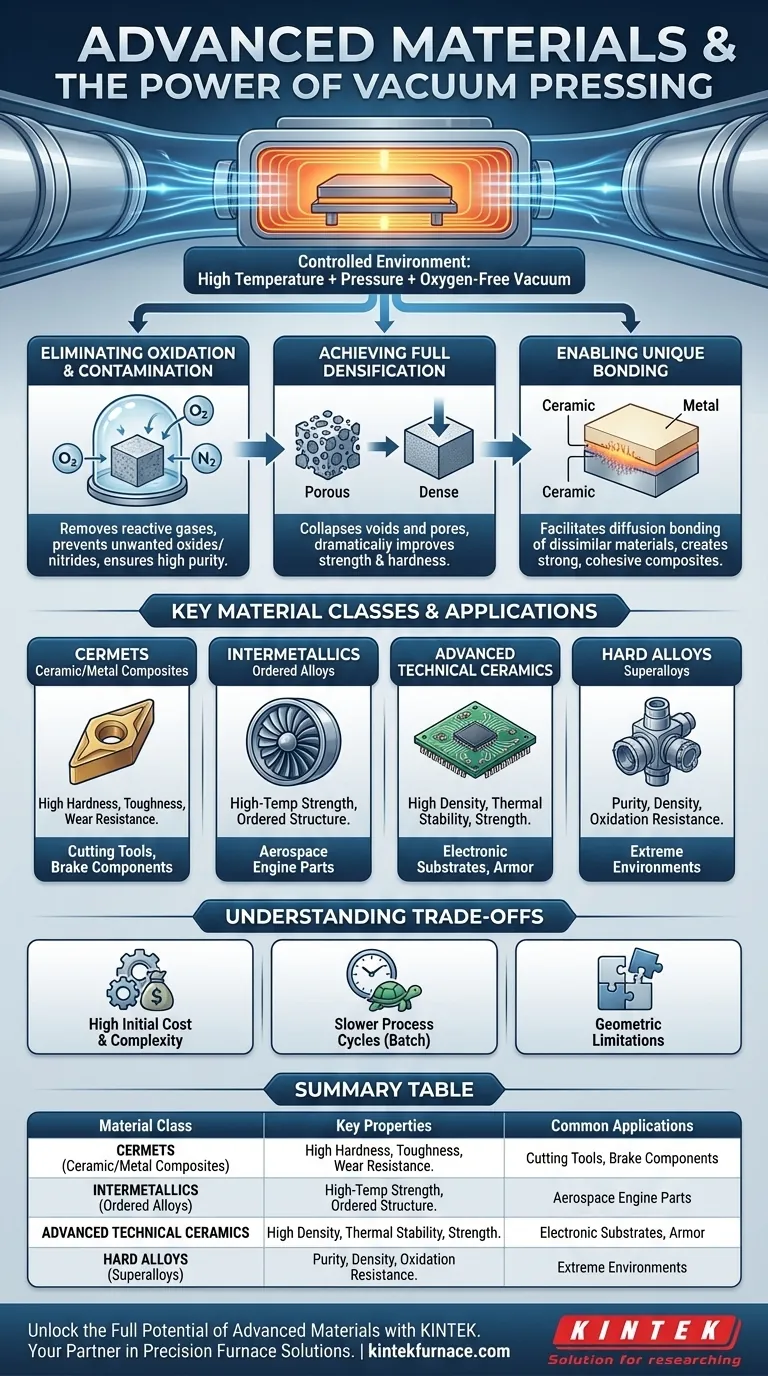

Why a Vacuum Environment is Critical

The unique capabilities of a vacuum press, also known as a vacuum hot press or sintering furnace, stem from its ability to manipulate three variables simultaneously: temperature, pressure, and atmosphere. This control is the key to producing advanced materials.

Eliminating Oxidation and Contamination

At the high temperatures required for sintering, most advanced materials are highly reactive with oxygen and nitrogen in the air. A vacuum removes these reactive gases.

This prevents the formation of undesirable oxides or nitrides that would compromise the material's final mechanical and thermal properties. The result is a material of much higher purity.

Achieving Full Densification

The combination of external pressure and a vacuum environment works to collapse internal voids and pores within the material.

This process, known as densification, is critical for improving mechanical properties like strength and hardness. A fully dense part has significantly higher performance and reliability than a porous one.

Enabling Unique Bonding Mechanisms

A vacuum press allows for the bonding of dissimilar materials, like ceramics and metals, which would otherwise be incompatible.

The controlled pressure and heat facilitate diffusion bonding at the interface, creating a strong, cohesive composite structure that combines the properties of each constituent.

Key Material Classes and Their Applications

The controlled environment of a vacuum press makes it uniquely suited for several classes of advanced materials.

Ceramic/Metal Composites (Cermets)

Cermets are composite materials that combine the high-temperature resistance and hardness of a ceramic with the toughness and ductility of a metal.

The vacuum press is essential for bonding these materials into a dense, uniform structure. Key applications include industrial cutting tools, wear-resistant coatings, and high-performance brake components.

Intermetallic Compounds

Intermetallics are highly ordered alloys with a defined crystal structure, distinct from a simple metal alloy. They often exhibit excellent strength at high temperatures but can be very brittle.

The vacuum press allows for their synthesis with precise stoichiometry and minimal impurities, which is critical for their performance in aerospace applications like turbine blades and engine components.

Advanced Technical Ceramics

While ceramics can be sintered in air, a vacuum hot press is used when maximum performance is required. This applies to materials like silicon carbide, boron nitride, and alumina.

The process eliminates residual porosity, dramatically increasing the material's density, strength, and thermal conductivity. This makes them suitable for demanding applications like electronic substrates, armor, and high-wear industrial parts.

Hard Alloys

Similar to advanced ceramics, many hard alloys and superalloys benefit from vacuum processing. The process ensures a pure, dense final product free from oxide inclusions that could act as failure points.

Understanding the Trade-offs

While powerful, vacuum press technology is not a universal solution. It involves specific challenges and limitations that must be considered.

High Initial Cost and Complexity

Vacuum hot press furnaces are sophisticated pieces of equipment that represent a significant capital investment. They require skilled operators and rigorous maintenance schedules.

Slower Process Cycles

Achieving a deep vacuum, ramping up to temperature, applying pressure, and cooling down is an inherently slow, batch-oriented process. This makes it less suitable for high-volume, low-cost manufacturing compared to conventional pressing and sintering.

Geometric Limitations

The need to apply uniform pressure often limits the complexity of the part geometries that can be produced. While advanced tooling is improving this, highly intricate shapes remain a challenge.

Making the Right Choice for Your Goal

The decision to use a vacuum press depends entirely on the performance requirements of the final material.

- If your primary focus is creating novel composite materials with superior wear resistance: A vacuum hot press is the ideal tool for bonding dissimilar materials like ceramics and metals into a fully dense cermet.

- If your primary focus is developing materials for extreme high-temperature environments: The vacuum press enables the formation of pure intermetallic compounds and non-oxide ceramics by preventing oxidation during synthesis.

- If your primary focus is maximizing the mechanical properties of a monolithic ceramic or alloy: The key advantage is the ability to eliminate porosity, which significantly increases density, hardness, and fracture toughness.

Ultimately, leveraging a vacuum press is about deliberately controlling the processing environment to unlock the full performance potential of advanced materials.

Summary Table:

| Material Class | Key Properties | Common Applications |

|---|---|---|

| Ceramic/Metal Composites (Cermets) | High hardness, toughness, wear resistance | Cutting tools, brake components, wear coatings |

| Intermetallic Compounds | High-temperature strength, ordered structure | Turbine blades, aerospace engine parts |

| Advanced Technical Ceramics | High density, thermal stability, strength | Electronic substrates, armor, industrial parts |

| Hard Alloys | Purity, density, resistance to oxidation | Superalloys for extreme environments |

Ready to enhance your material fabrication with precision? KINTEK specializes in advanced high-temperature furnace solutions, including vacuum hot presses. Leveraging exceptional R&D and in-house manufacturing, we offer products like Vacuum & Atmosphere Furnaces with deep customization to meet your unique experimental needs. Whether you're developing cermets, intermetallics, or ceramics, our expertise ensures superior density, purity, and performance. Contact us today to discuss how we can support your innovative projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure